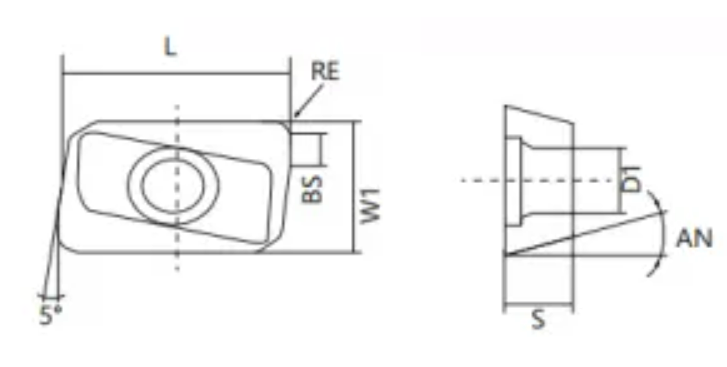

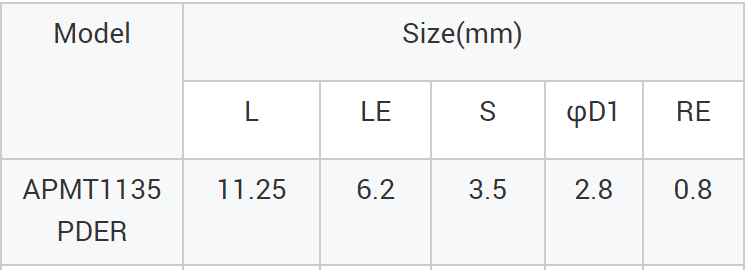

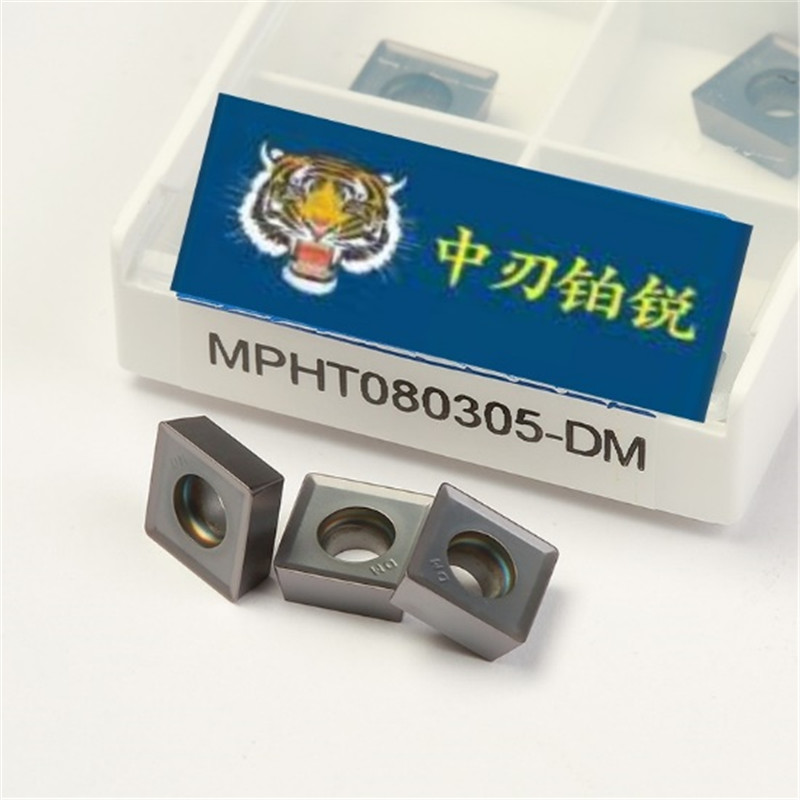

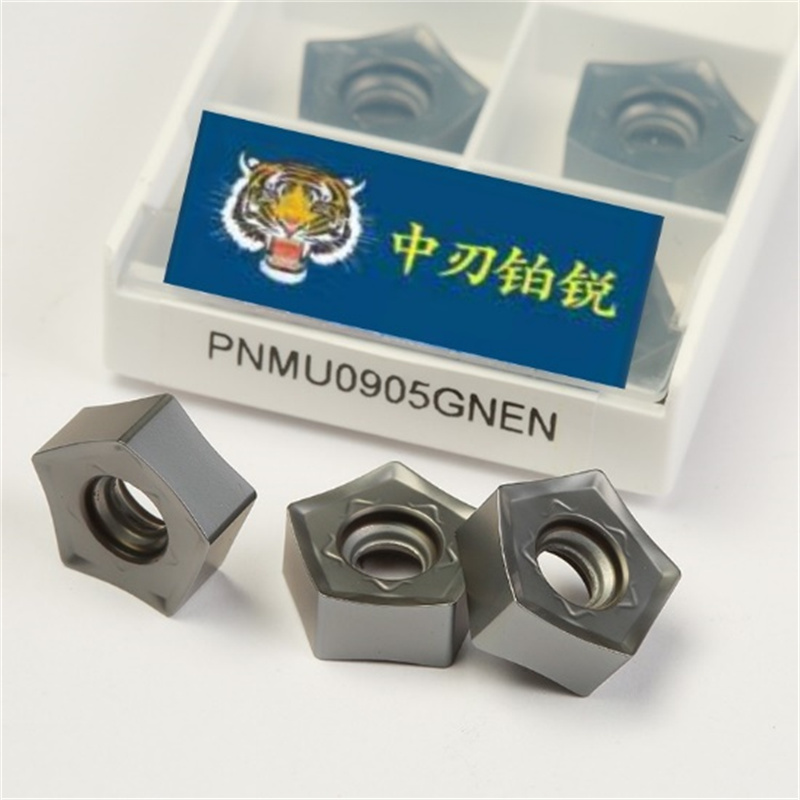

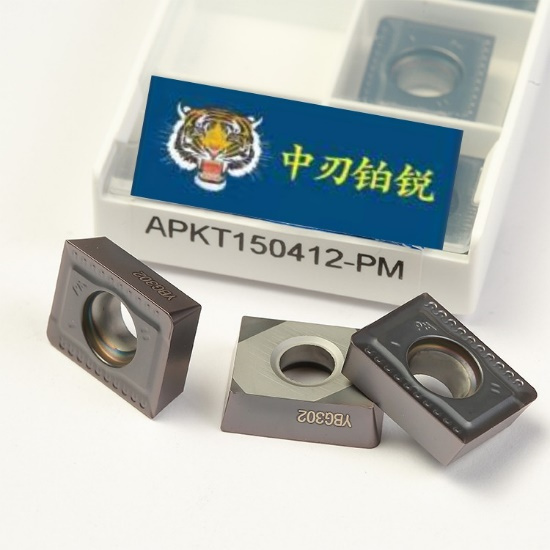

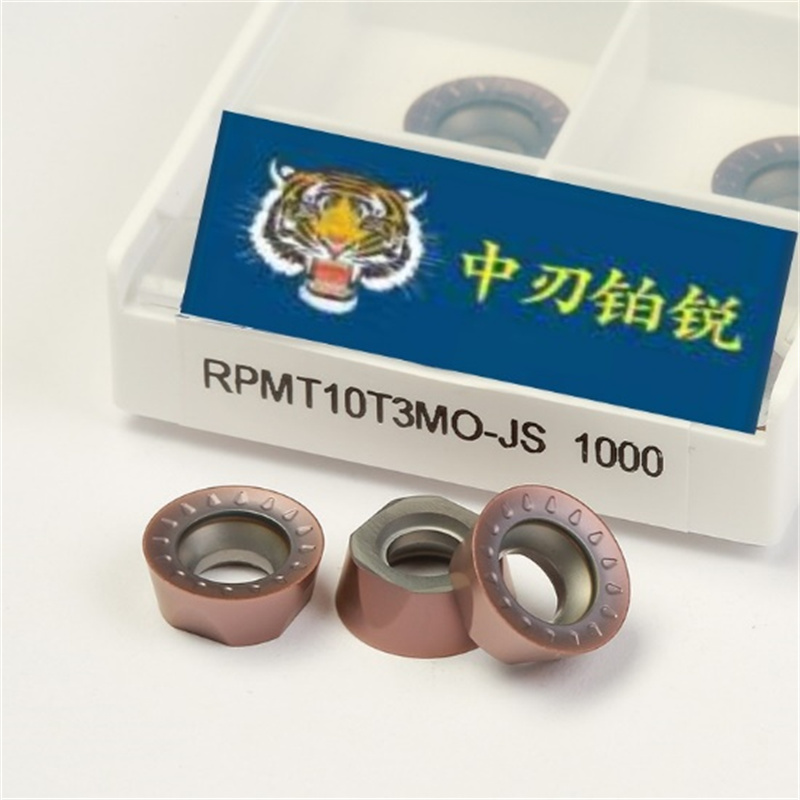

Tungsten Carbide Turning Indexable Insert APMT1135 for amuninum/stainless steel/Cast Iron

Basic Information

APMT1135 is belong to square shoulder milling, which generates two faces at the same time, which requires a combination of peripheral milling and face milling. Shoulder face mills of conventional designs are often capable of milling “true”, 90-degree shallow shoulders. Many shoulder face mills are universal cutters, and can be used advantageously for making holes. Shoulder milling can be done with traditional shoulder milling cutters, end mills, long edge milling cutters, side milling cutters and face milling cutters can also be used.

Main Application:

For processing carbon steel, cast iron, stainless steel

Industry of application:

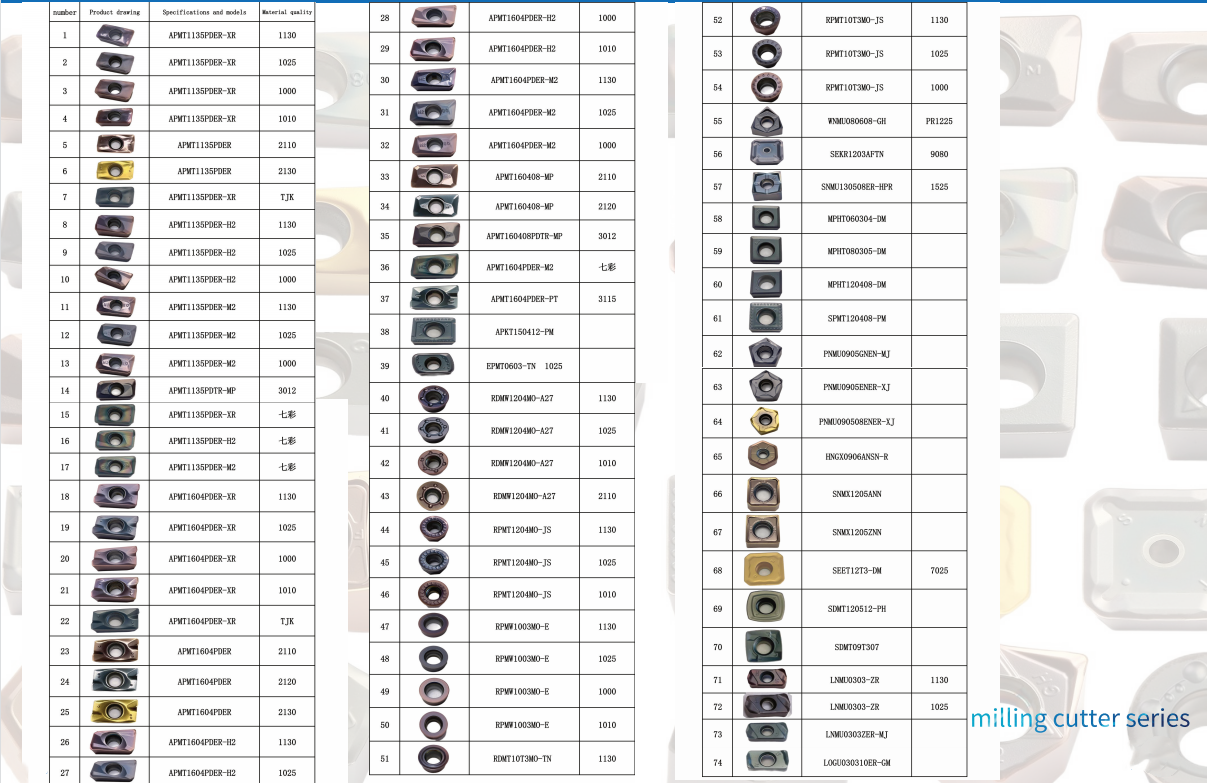

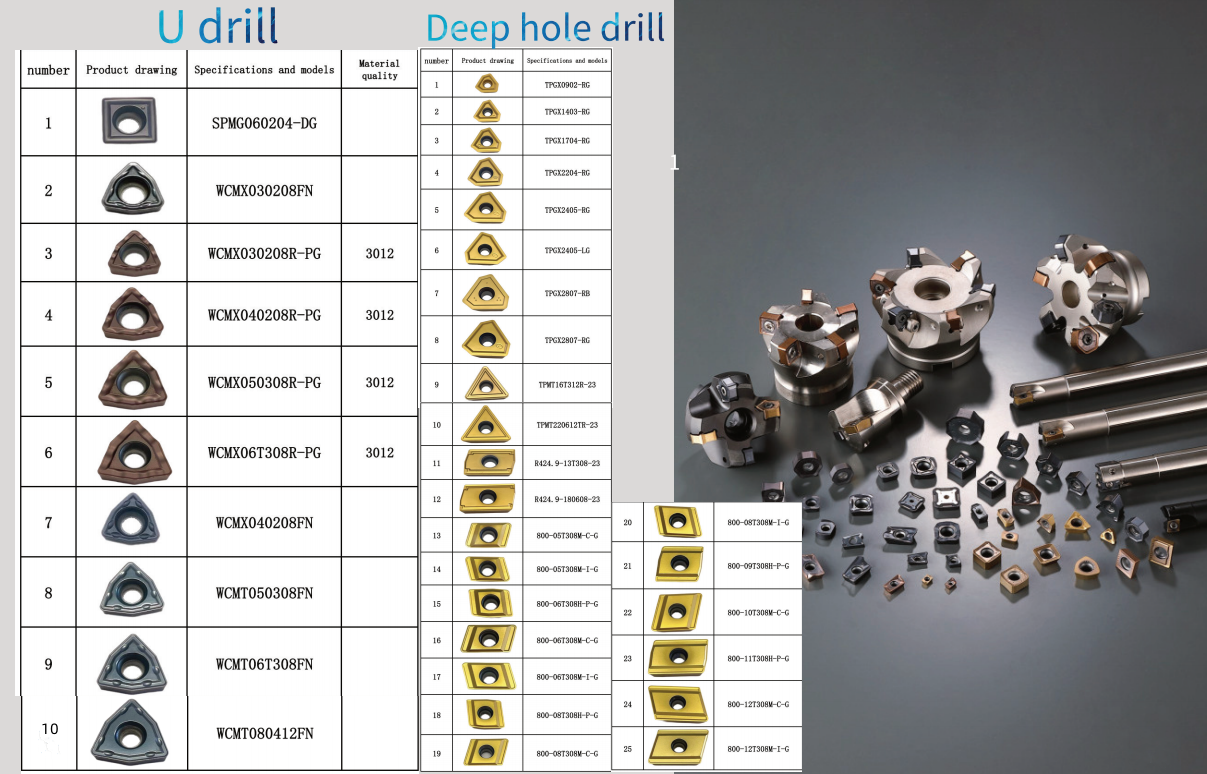

CNC turning and milling tungsten carbide tools products inserts are widely used in: Automotive manufacturing industry, Mold manufacturing industry, Aviation industry, Defense industry, Heavy processing industry and many other field.

we can produce various types tungsten carbide cutting tools insert according to different customized drawings.

we can provide the overall supporting solutions for the machining field.

Production Equipment

QC Equipments

Certificates

Advantages

1. Efficiently solved build up edge work hardening and other machining problems.

2. Cutting edge inclination designation is good to control chip flow direction and obtains excellent surface quality.

3. Sharp cutting edge, small cutting force.

4. Good machining surface quality.

5. Special chip breaker design to keep cutting edge sharp and safe.

6. Good anti impact resistance.

7. Excellent tool life time.

Features

1.special surface treatment with coating.

2.suit for high precision processing.

3.fast delivery and top-quality service.

4. High quality with competitive price.

5. Widely used in industry of metalworking machinery

6. High precision, easy replacement, general use.