Fine Polished Good Quality Cvd Coating Rough Milling Insert Lathe Carbide Apmt1135pder 1120 Carbide Inserts Factory Wholesale

Short Description

ungsten Carbide Cutting Insert with different shapes and material for different cutting purpose and with high wear impact resistance which is a good substitution of ceramic insert, coating insert and alloy insert. It is suitable for hot process composite material for surface refurbishing and making capable to provide comprehensive coatings to enhance the wear resistance, thermal resistance, corrosion resistance and impact resistance of protect surface and special coatings of sealing, insulation and super-conduction.

Basic Information

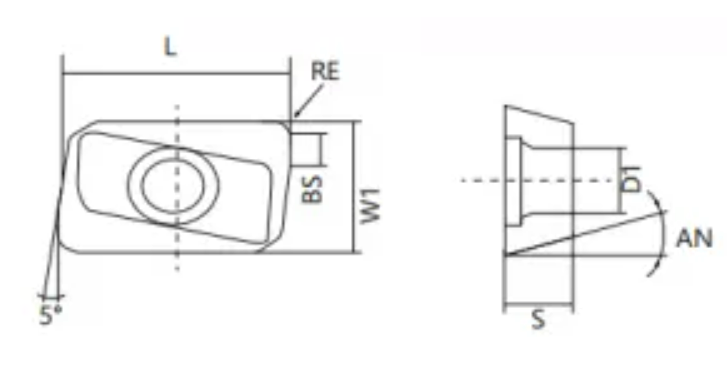

Carbide APMT PVD Coated inserts are commonly used for indexable square shoulder end milling cutters and face milling cutters. The APMT inserts are with precision-molded I.C., positive molded chip breaker. They have a sharp and honed cutting edge and 11° relief angle. They are with screw holes created in compliance with ISO. Typically, it is viewed as with 2 cutting edges. However, they actually have 4 cutting edges. when they are installed on 90° indexable milling cutters and both edges become dull, they can be installed on 75° indexable milling cutters  and continue other milling applications with the other two edges.APMT will be a great choice for end users, since it can significantly improve productivity.

Our carbide inerts has very high chemical stability,cutting process, the friction of coefficient is small,low cutting temperature,can prevent the process of cuttib the inter-atomic diffusion of materials, anti-stick knife and wear resistance is also much higher than the hard alloy.but also has better red hardness and anti-crescent crater wear performance.

Industry of application:

CNC turning and milling tungsten carbide tools products inserts are widely used in: Automotive manufacturing industry, Mold manufacturing industry, Aviation industry, Defense industry, Heavy processing industry and many other field.

we can produce various types tungsten carbide cutting tools insert according to different customized drawings.

we can provide the overall supporting solutions for the machining field.

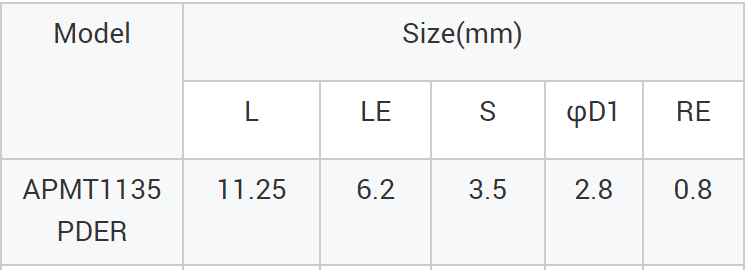

Product Specifications

QC Equipments

Production Equipment

QC Equipments

Certificates

Advantages

1. Efficiently solved build up edge work hardening and other machining problems.

2. Cutting edge inclination designation is good to control chip flow direction and obtains excellent surface quality.

3. Sharp cutting edge, small cutting force.

4. Good machining surface quality.

5. Special chip breaker design to keep cutting edge sharp and safe.

6. Good anti impact resistance.

7. Excellent tool life time.

Features

1.special surface treatment with coating.

2.suit for high precision processing.

3.fast delivery and top-quality service.

4. High quality with competitive price.

5. Widely used in industry of metalworking machinery

6. High precision, easy replacement, general use.