Tungsten Carbide Milling Inserts Apmt1135pder 1130 cutting tools

Short Description

Tungsten Carbide Cutting Insert with different shapes and material for different cutting purpose and with high wear impact resistance which is a good substitution of ceramic insert, coating insert and alloy insert. It is suitable for hot process composite material for surface refurbishing and making capable to provide comprehensive coatings to enhance the wear resistance, thermal resistance, corrosion resistance and impact resistance of protect surface and special coatings of sealing, insulation and super-conduction.

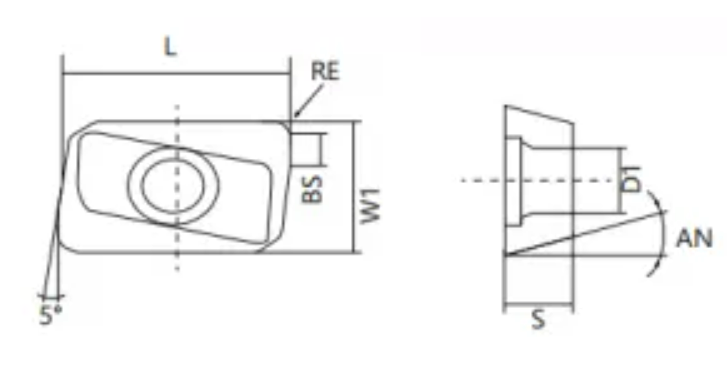

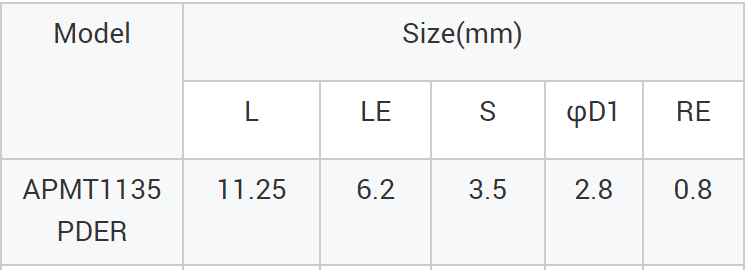

Product Specifications

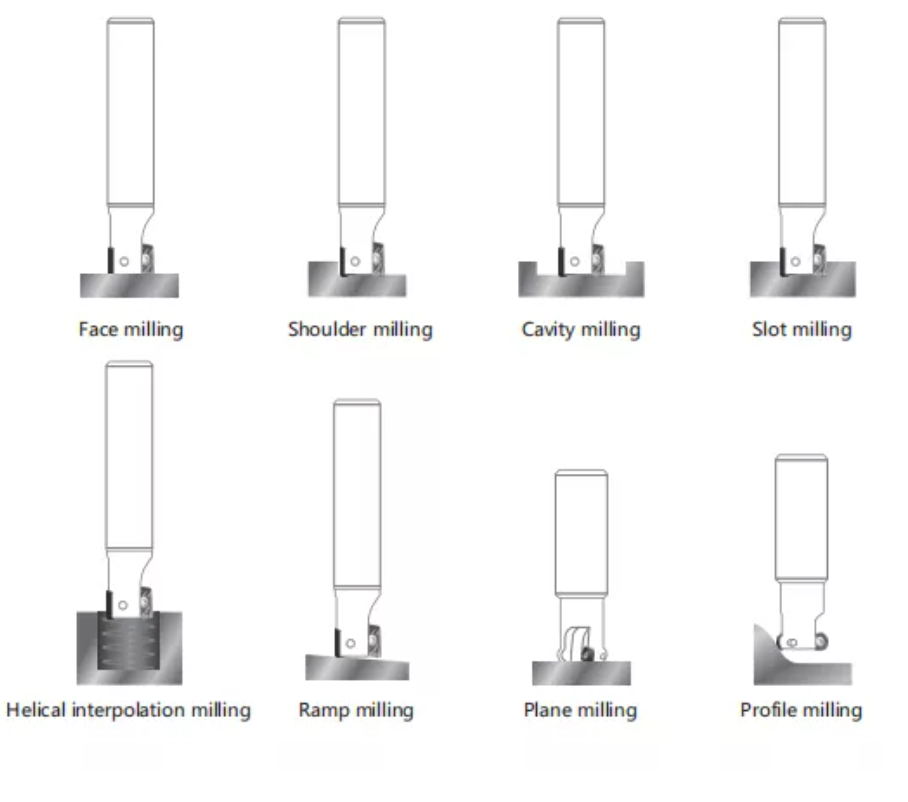

Whether you need a general milling or heavy milling inserts for face milling, shoulder milling, slot milling, profile milling, or ramp milling, or even milling higher requirements of surface smoothness, Our engineer can turn your design into a milling insert in just days.

Production Equipment

QC Equipments

Certificates

Advantages

1. Efficiently solved build up edge work hardening and other machining problems.

2. Sharp cutting edge, small cutting force.

3. Good machining surface quality.

4. Excellent tool life time.

5. Small orders are acceptable for quick delivery and to help you reduce stock cost.

Features

1. Efficiently solved build up edge work hardening and other machining problems.

2. Sharp cutting edge, small cutting force.

3. Good machining surface quality.

4. Excellent tool life time.

5. Small orders are acceptable for quick delivery and to help you reduce stock cost.