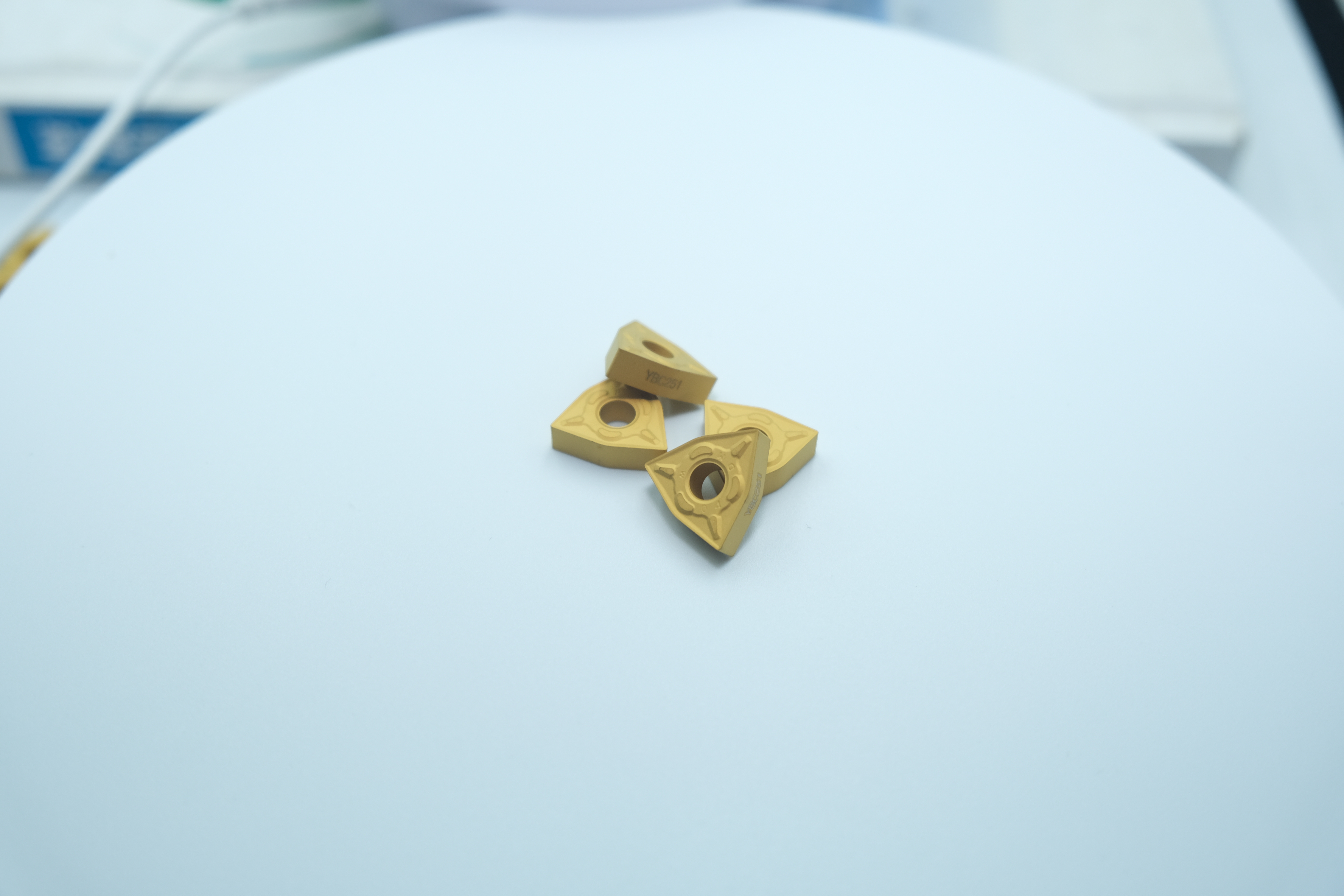

Tool tip wear refers to the wear of the back tool face of the tool tip arc and the adjacent secondary back tool face, which is the continuation of the wear of the back tool face on the tool. Because the heat dissipation conditions here are poor and the stress is concentrated, the wear speed is faster than the back tool surface, and sometimes a series of small trenches with spacing equal to the feed amount will be formed on the back tool surface, which is called groove wear. They are mainly caused by the hardened layer of the machined surface and the cut lines. Grooving wear is most likely to be caused when cutting difficult-to-cut materials with large work-hardening tendency. Tool tip wear has the greatest influence on workpiece surface roughness and machining accuracy.

Post time: Mar-06-2024