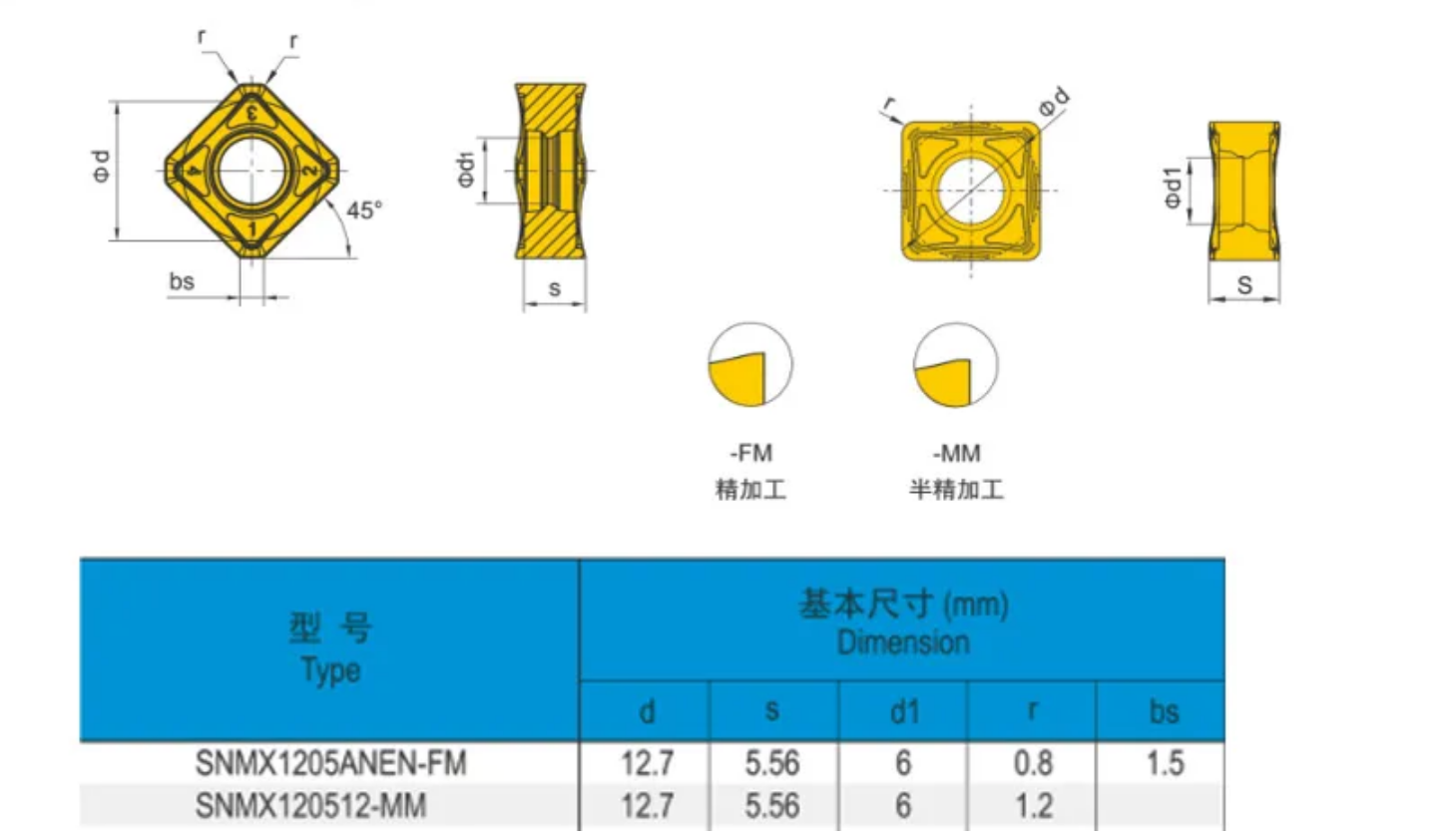

Carbide Indexable Inserts SNMX1205ANN Face Milling Cutter Fast Feed Inserts

Basic Information

Features of carbide insert SNMX

1:Used for continuously and discontinuously cutting for reflectal, birmasil(Si<12%)

2:It can minimize built-up edge and get a good finished surface in a wide range of cutting speed with little cutting resistance.

3:We can also provide carbide inserts which are not in our catalogues machining aluminum,steel and stainless, cast iron materials as well as other metal cutting inserts according to your samples and drawings.

4. Superfine particle substrate to ensure the wear resistance and micro crack resistance of the blade,uncoated grade,Surface polishing treatment which can reduce built-up edge to obtain good surface quality of workpiece.

Product Specifications

Coating Display

Package and Delivery

100% anti-water package.One plastic pipe pack one piece,10 pcs per group. Put goods enclosed with air bubble paper into box. Other package is accepted according to customer's requirement.

1.If the quantity of order is not very big,we could send them to you by express delivery. such as TNT,DHL,UPS or EMS etc.

2.If order is big ,we will suggest you use Air Shipping or Sea Shipping through your designated Freight forwarder agent. our long-term cooperated agents ate also available.

3.About shipping time ups: about 7-10 working days FedEx: about 4-8 working days DHL: about 3-5 working days By sea: about 30 working days.

Certificates

Production Equipment

QC Equipments

Advantage

1.Tungsten carbide material

2.Large stock can deliver fast

3.High wear and abrasive resistance

4.Attractive price and high quality with good service

5.Precision ground and polished

6.High hardness and PVD/CVD coating

7.Dimensionally accurate, durable and reliable performance

8.Widely used in industry of metalworking machinery

Why choose us

1.Advanced Equipment: Our workshop is fully equipped with spray tower, ball mill, automatic press, low pressure sintering furnace, tool grinder, CNC grinder and other equipment.

2. Cost-effective price: Cooperate with LONBOND and OERLIKON coating companies to ensure that your products are beautiful and have a longer tool life.

3.Advanced testing equipment: include hardness tester, density meter, high-power microscope, magnetic tester, metallographic tester, etc.

4.Clean and tidy environment: Managed in strict accordance with ISO9001 and 6S standard systems, scientifically and comprehensively control every link in the production process, guarantee product quality while efficient production, and provide customers with high-quality products.

5. Competitive shipping charge: Have cooperated with our shipping agent for more than 10 years. They can give us competitive price to save your money.