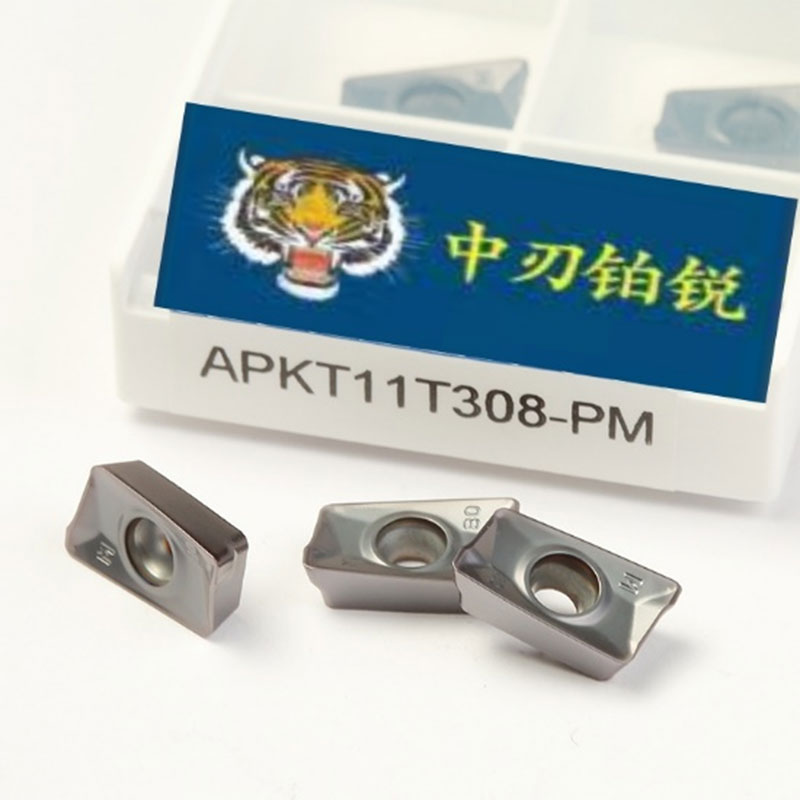

Tungsten Carbide Insert APKT160408 for Milling Cutting Tools CNC Machining

Basic Information

APKT for helical milling is quadrilateral shape of turning insert (85°). Insert with clearance under main cutting edge. Hole through insert and single sided chip breaker. The 3D helical cutting edge can deal with less cutting force. As such most face milling, shoulder milling cutters are using indexable inserts with wedge type clamping or screw-on type clamping to achieve high-quality machining. Our APKT inserts will be your premium choice for helical milling.

Application

- Main Application: For steel, stainless steel, Cast iron, Aluminum processing

- Industry of application: CNC turning and milling tungsten carbide tools products inserts are widely used in: Automotive manufacturing industry, Mold manufacturing industry, Aviation industry, Defense industry, Heavy processing industry and many other field.

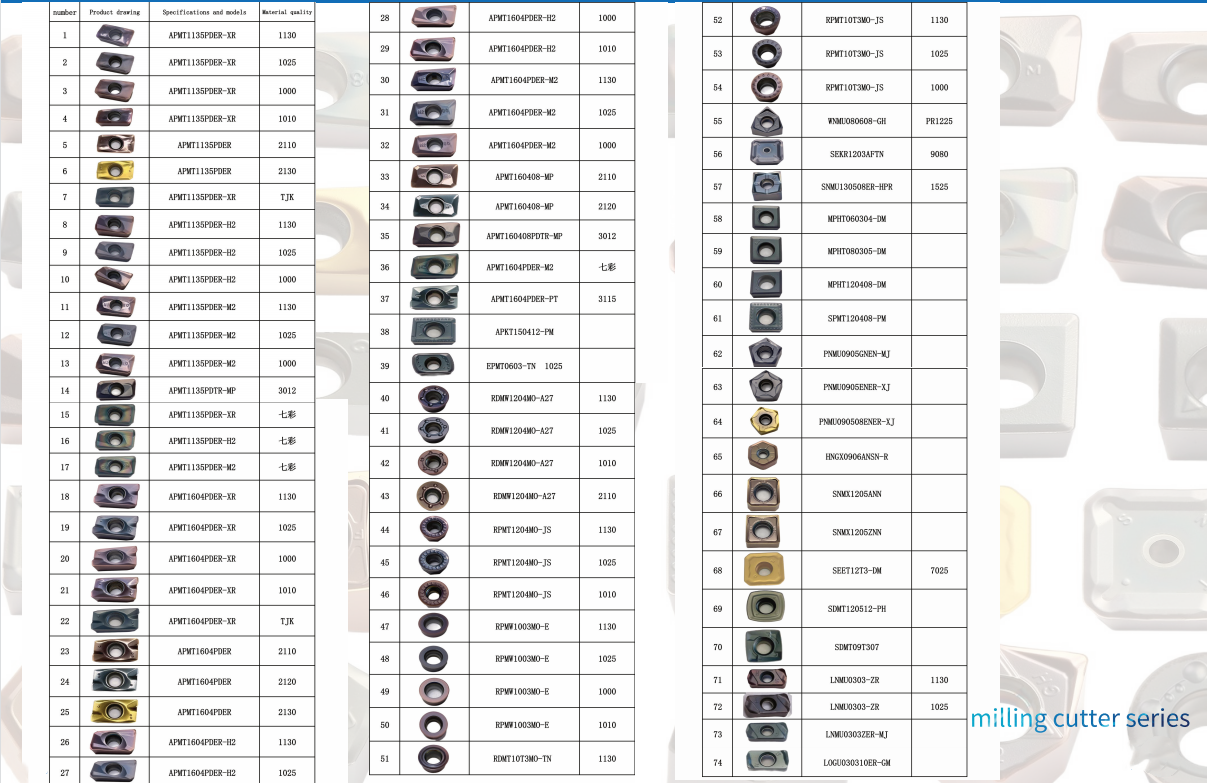

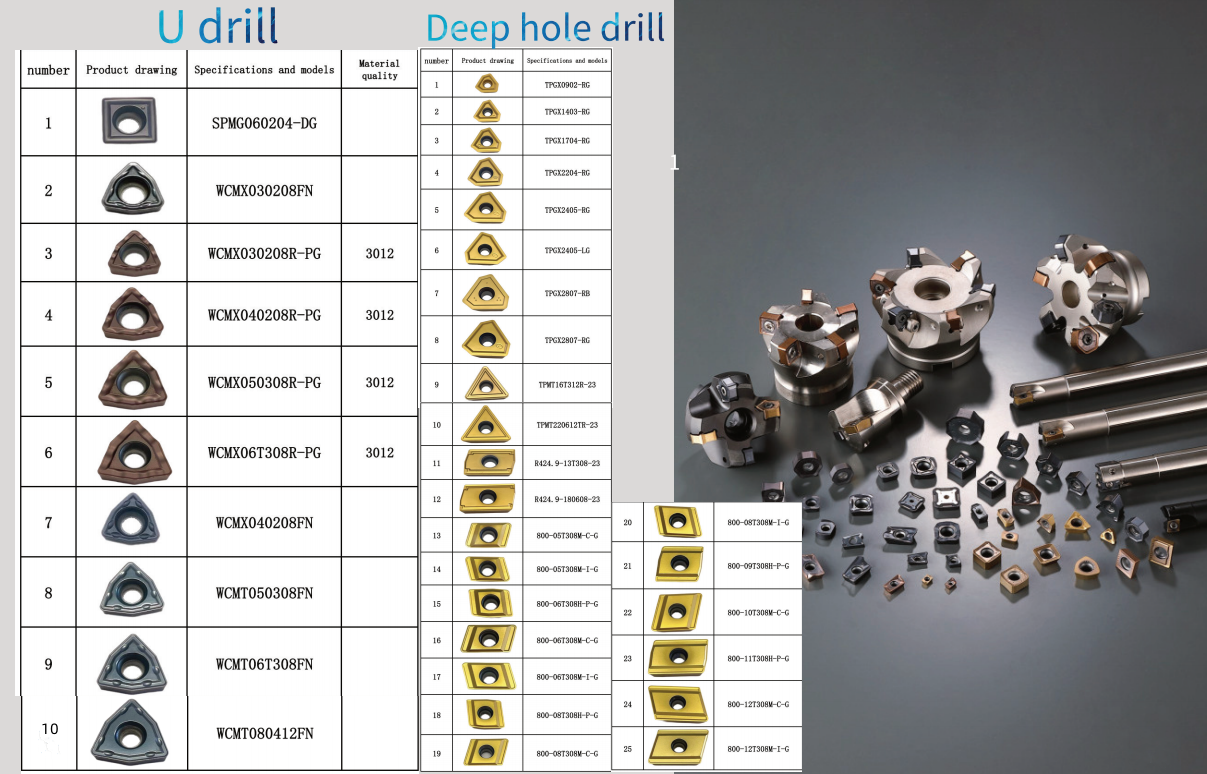

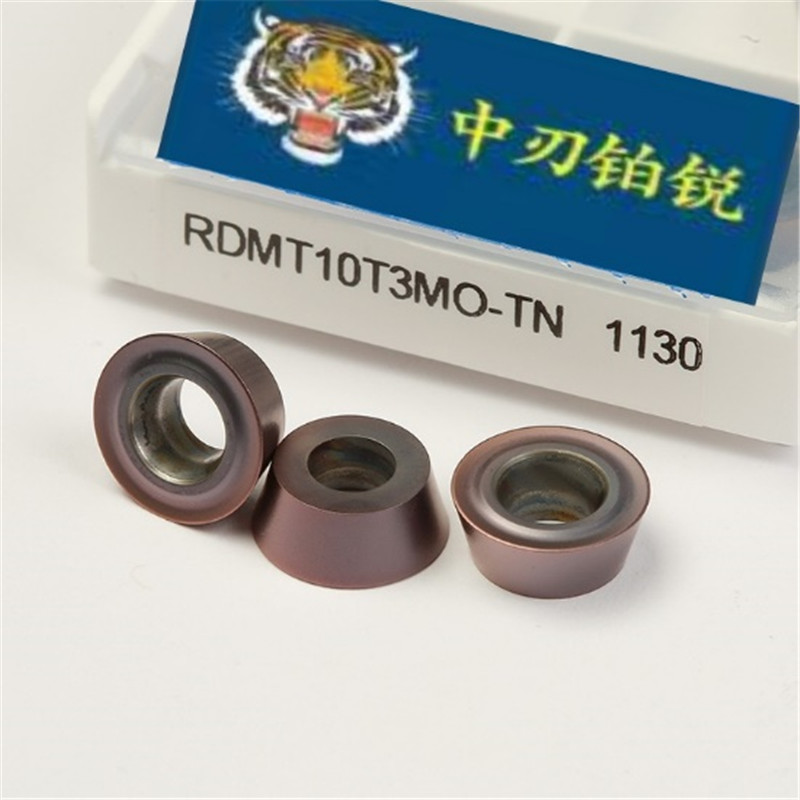

we can produce various types tungsten carbide cutting tools insert according to different customized drawings.

we can provide the overall supporting solutions for the machining field.

Certificates

Production Equipment

QC Equipments

Advantages

1. Efficiently solved build up edge work hardening and other machining problems.

2. Cutting edge inclination designation is good to control chip flow direction and obtains excellent surface quality.

3. Sharp cutting edge, small cutting force.

4. Good machining surface quality.

5. Special chip breaker design to keep cutting edge sharp and safe.

6. Good anti impact resistance.

7. Excellent tool life time.

Features

1. Dimensionally accurate, durable and reliable performance,reduce processing costs

2. High quality with competitive price.

3. Widely used in industry of metalworking machinery

4. High precision, easy replacement, general use.

5.Various types and also can be made as per client's request.