High quality Indexable Carbide Milling Inserts PVD Coating APMT1604PDER-M2 Direct supply from manufacturer

Basic Information

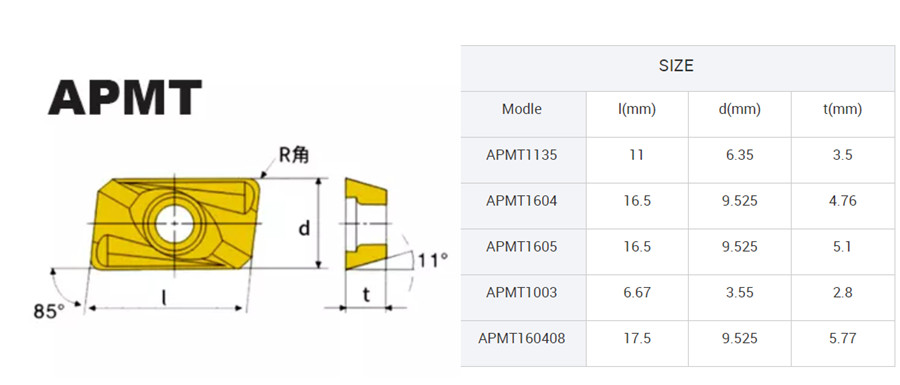

Carbide APMT PVD Coated inserts are commonly used for indexable square shoulder end milling cutters and face milling cutters. The APMT inserts are with precision-molded I.C., positive molded chip breaker. They have a sharp and honed cutting edge and 11° relief angle. They are with screw holes created in compliance with ISO. Typically, it is viewed as with 2 cutting edges. However, they actually have 4 cutting edges. when they are installed on 90° indexable milling cutters and both edges become dull, they can be installed on 75° indexable milling cutters  and continue other milling applications with the other two edges.APMT will be a great choice for end users, since it can significantly improve productivity.

1.Type: APMT1604PDER-M2

2.Material:100% raw new material of tungsten carbide

3.Coating: PVD/CVD

4.Place of Origin:Shandong, China

5.Brand Name:Zhongbian Brite

6.Usage:External Turning Tool

7.Application:Machining steel, stainless steel

8.Package Type:10 piece in one plastic box

Application

Main Application: For processing carbon steel, cast iron, stainless steel

Product Specifications

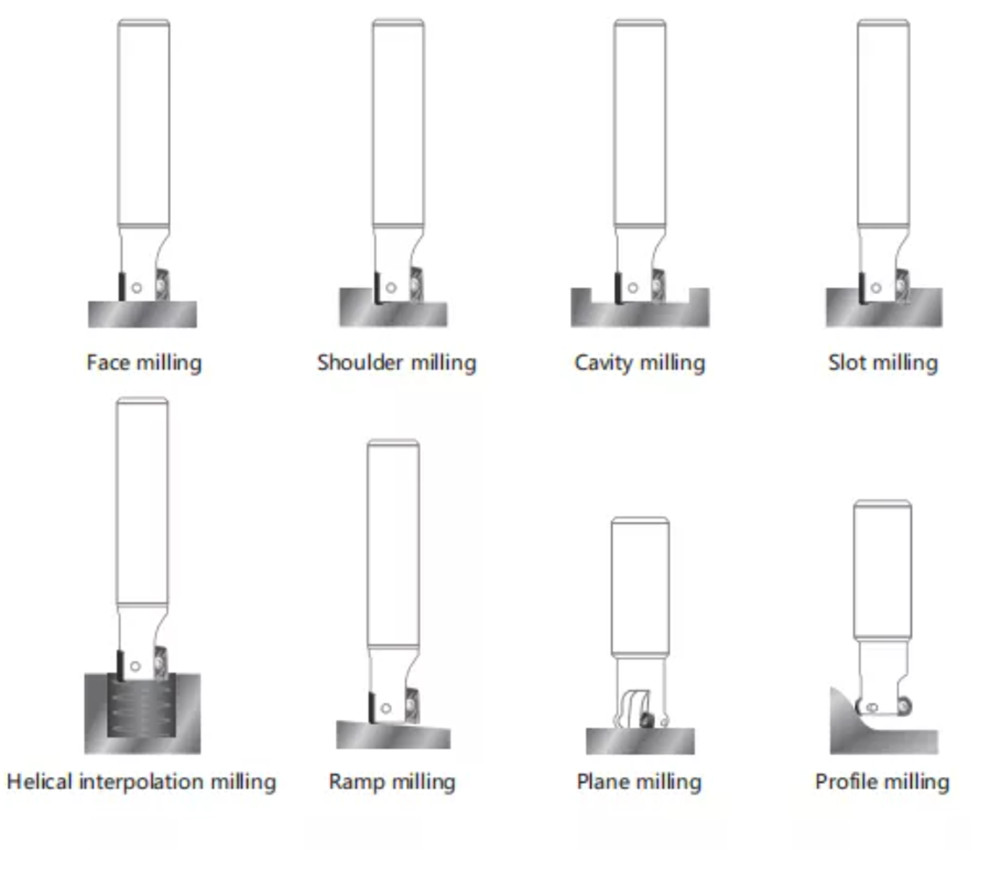

Whether you need a general milling or heavy milling inserts for face milling, shoulder milling, slot milling, profile milling, or ramp milling, or even milling higher requirements of surface smoothness, Our engineer can turn your design into a milling insert in just days.

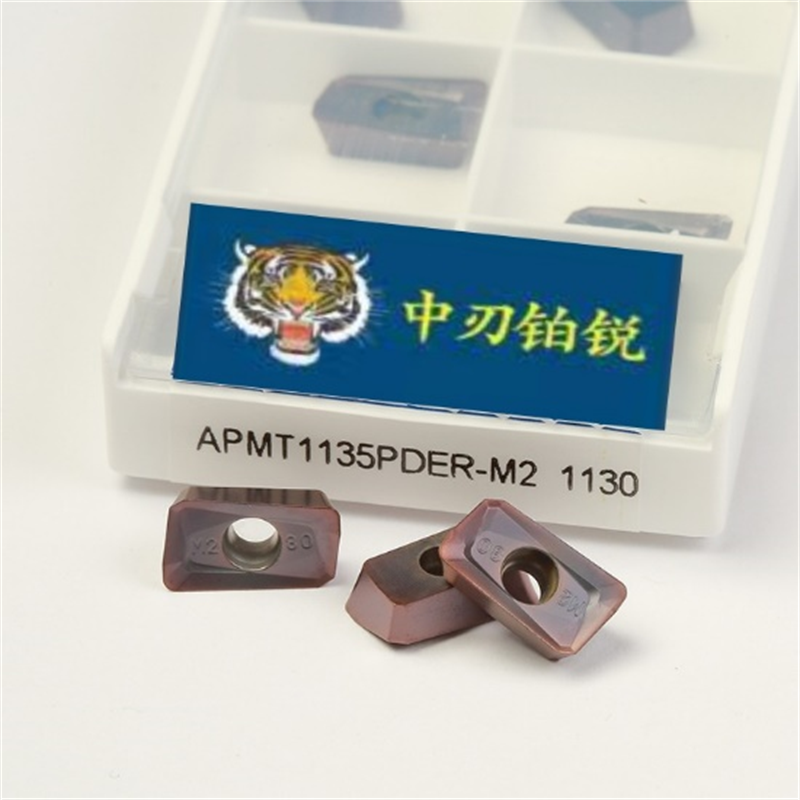

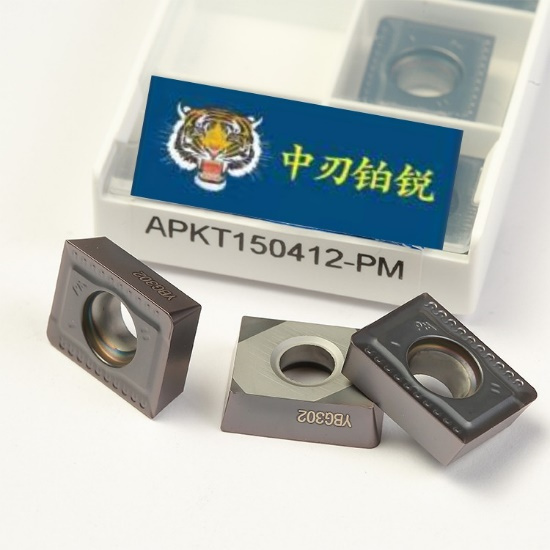

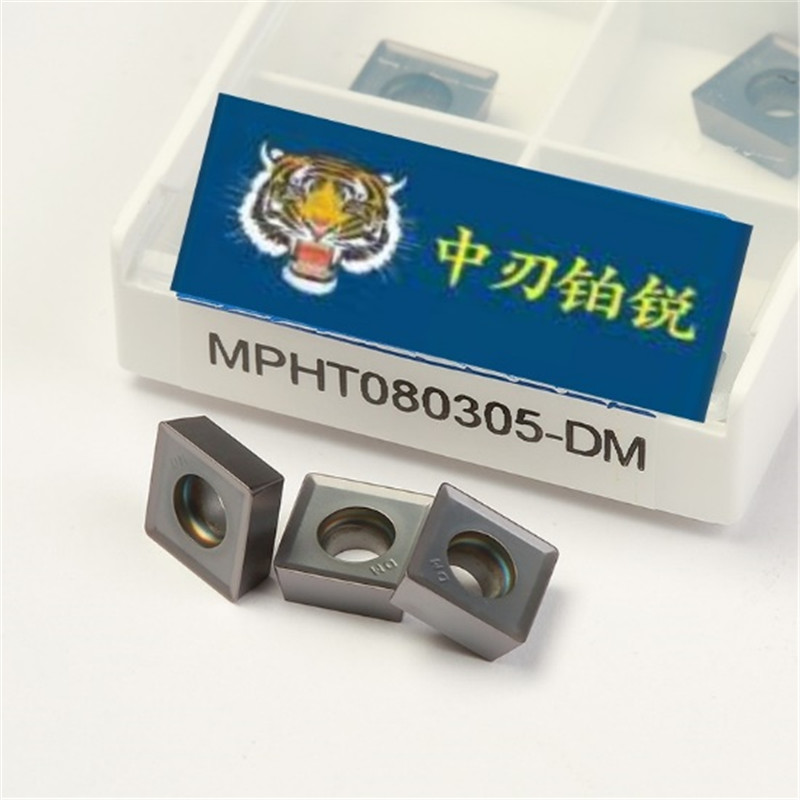

Coating Display

Certificates

Production Equipment

QC Equipments

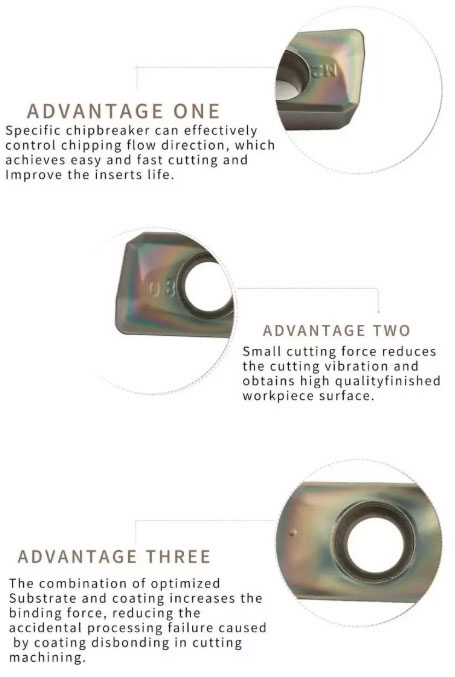

Advantages

1, High hardness (91.5~93HRA)

2, Good hot hardness (can reach 900~1000°C, keep 60HRC)

3, Excellent wear resistance

4, Higher cutting speed

5, Excellent production efficiency

6, Short production cycle.

FAQ

Are you a trading company or manufacturer?

A: We are a professional and excellent manufacturer, welcome to visit us.

Do you provide samples ? Is it free or extra?

A: Yes, we could offer the free sample (stock items including carbide insert, parting and grooving, milling etc) for testing, but shipping freight is to be paid by customer.

Is your company accept customization?

A:OEM and ODM are available. We have our own professional R&D team to satisfied your cutting tools solution. We also have our own mold department.

What is your payment terms?

L/C,T/T, Paypal, Western Union for different circumstances.

What's your delivery way?

Express delivery by DHL, FEDEX , TNT, EMS, UPS, sea shipping and by air are available for large volume order or for your request.

Can you produce special carbide tools?

Yes, we can produce special carbide tools according to your drawings or samples.