Indexable CNC cutting tools milling cutter tungsten Carbide Inserts SEET12T3 for CNC Machining

Basic Information

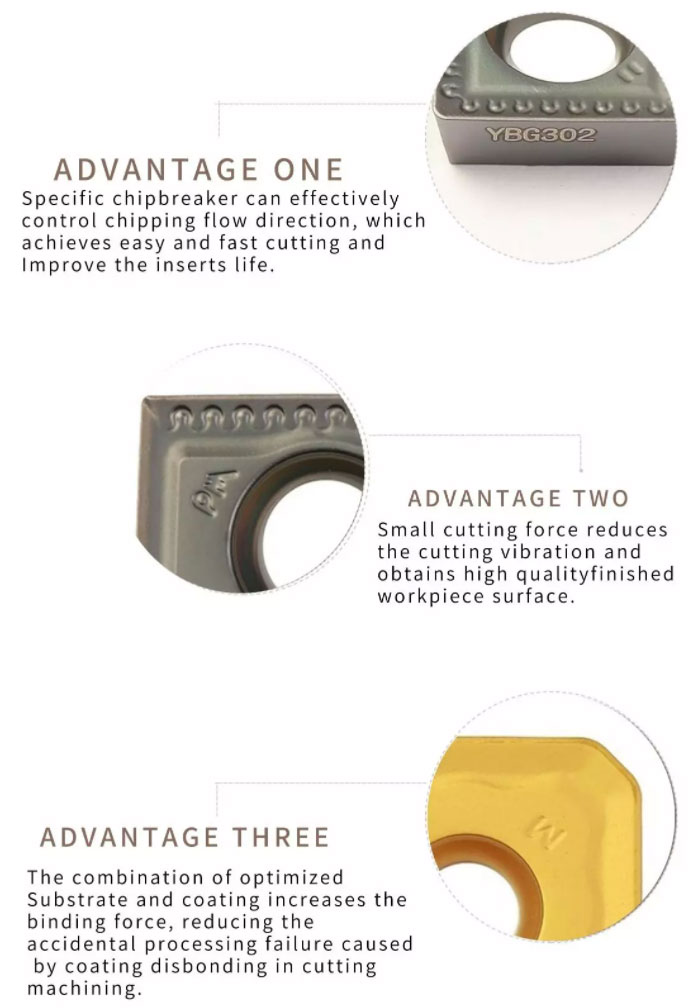

Our carbide cutting insert has high chemical stability, the friction coefficient is small in the cutting process, the cutting temperature is low, can prevent the material interatomic diffusion in the cutting process, the anti-stick tool and wear resistance is much higher than hard alloy. But also has better red hardness and crater wear resistance.

Main Application: For processing carbon steel, cast iron, stainless steel

Material Grade Introduction

Application

Main Application: For processing carbon steel, cast iron, stainless steel

Industry of application:

CNC turning and milling tungsten carbide tools products inserts are widely used in: Automotive manufacturing industry, Mold manufacturing industry, Aviation industry, Defense industry, Heavy processing industry and many other field.

we can produce various types tungsten carbide cutting tools insert according to different customized drawings.

we can provide the overall supporting solutions for the machining field.

Product Specifications

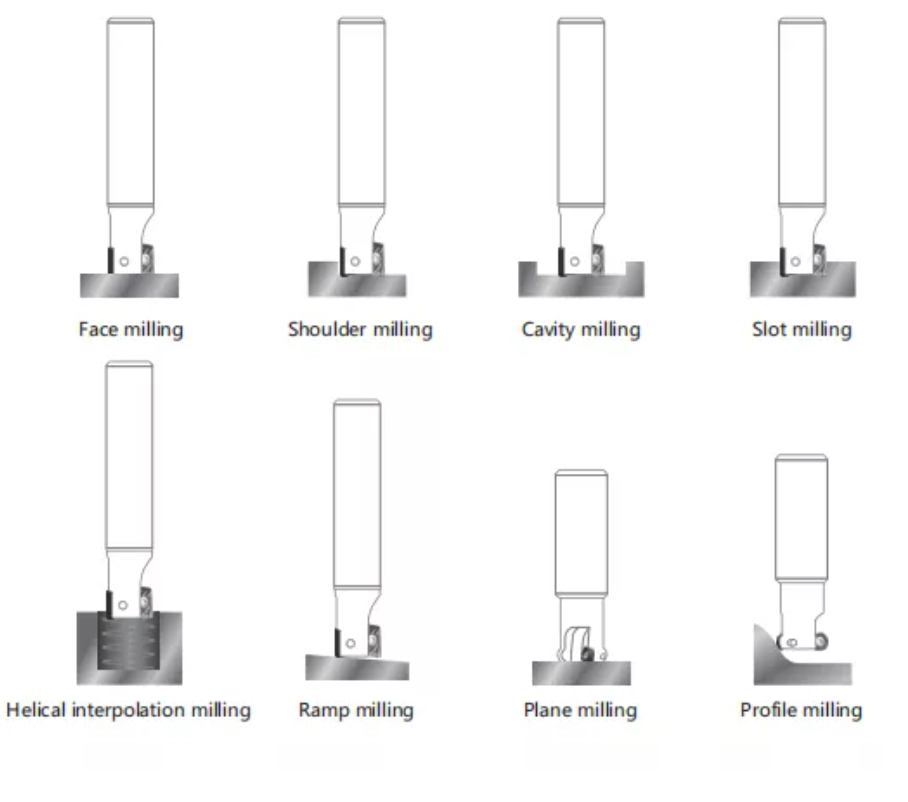

Whether you need a general milling or heavy milling inserts for face milling, shoulder milling, slot milling, profile milling, or ramp milling, or even milling higher requirements of surface smoothness, Our engineer can turn your design into a milling insert in just days.

Coating Display

Certificates

Production Equipment

QC Equipments

FAQ:

Q: 1. Are you a trading company or manufacturer?

A: Our company is a professional producer with more than 10 years experience in this field.

Q: 2. Can you produce Special Carbide Tools?

A: Yes, we can. We can produce according to your drawing or sample.

Q: 3. What's your MOQ?

A: 10 pieces.

Q: 4. How long is the delivery time?

A: Stock product: We have stock for some regular product, we can send them immediately once order confirmed. For Non-stock product: Within 10-15 days

Q: 5. Do you provide samples?

A: Yes, we can offer samples for testing as support.