Fast feed milling cutter LNMU0303ZER Carbide insert LNMU External turning insert LNMU0303 Lathe part tool

Basic Information

1.Type: LNMU0303ZER

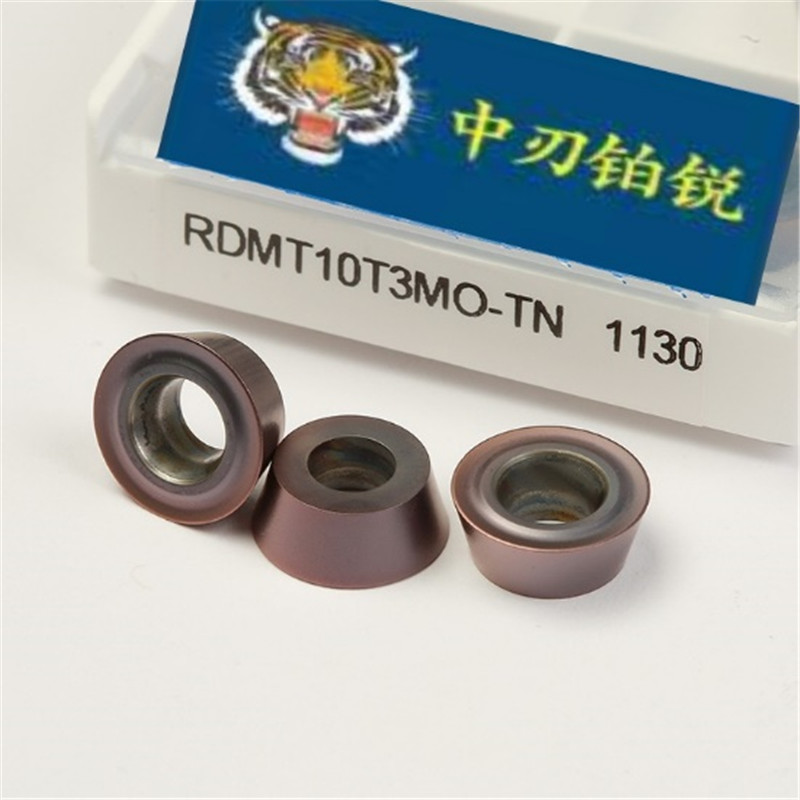

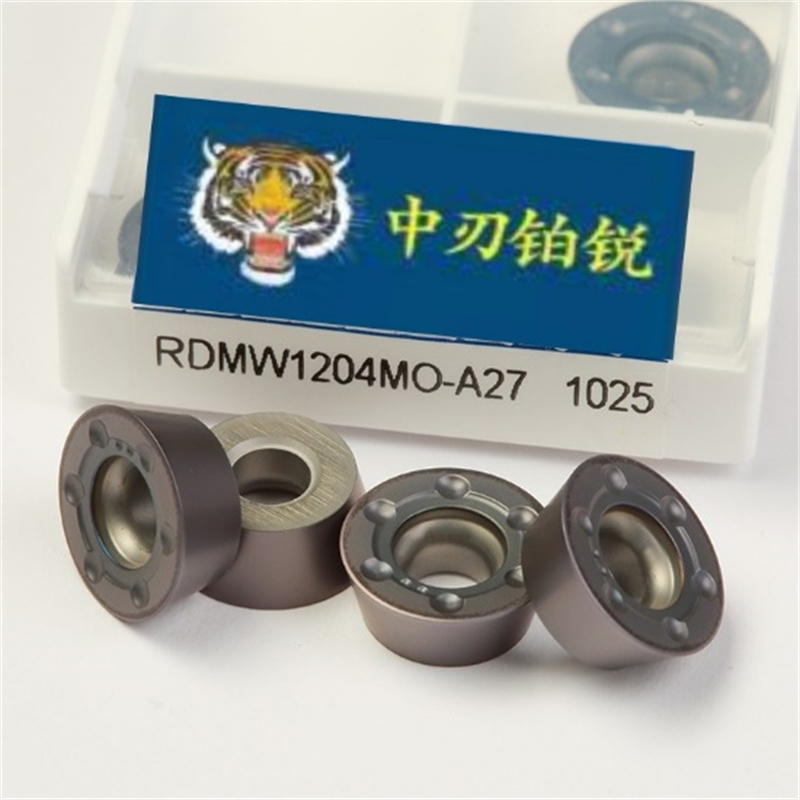

2.Material: 100% raw new material of tungsten carbide

3.Application: Machining steel, stainless steel

4.Coating: CVD/PVD

5.Standard: ISO international standard

6.Stock: Ask us

Application

Main Application: For processing carbon steel, cast iron, stainless steel

Industry of application: CNC turning and milling tungsten carbide tools products inserts are widely used in: Automotive manufacturing industry, Mold manufacturing industry, Aviation industry, Defense industry, Heavy processing industry and many other field.

we can produce various types tungsten carbide cutting tools insert according to different customized drawings.

we can provide the overall supporting solutions for the machining field.

Product Specifications

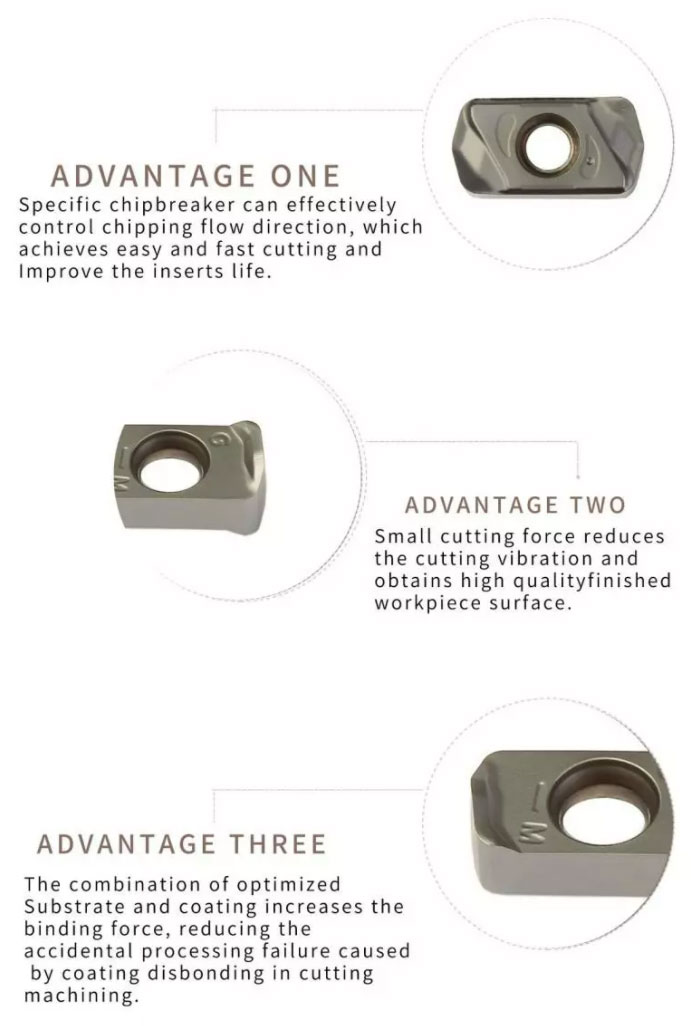

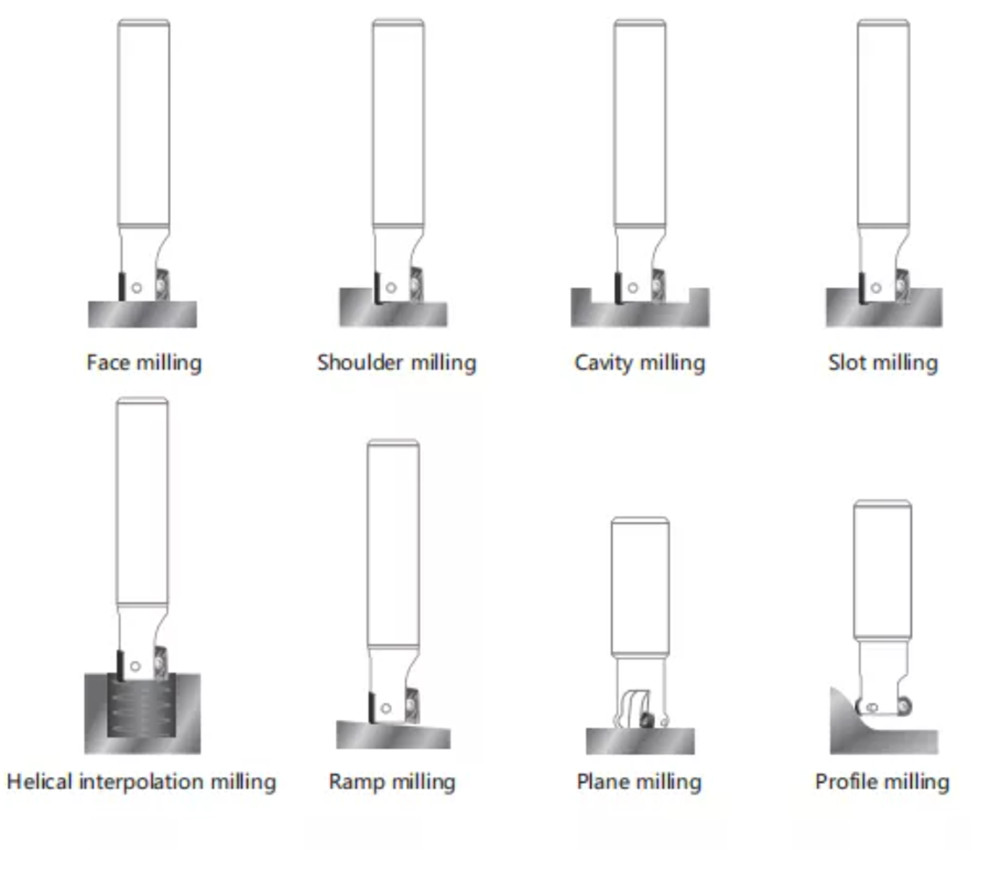

Whether you need a general milling or heavy milling inserts for face milling, shoulder milling, slot milling, profile milling, or ramp milling, or even milling higher requirements of surface smoothness, Our engineer can turn your design into a milling insert in just days.

Coating Display

Certificates

Production Equipment

QC Equipments

Features

1. Highly wear-resistant material specially designed for stainless steel material processing

2. Precise dimension and high accuracy

3. Strict quality management system to guarantee the consistent quality

4. Precision ground and polished, perfect cutting effect

5. PVD coating ensure the longer tool life.