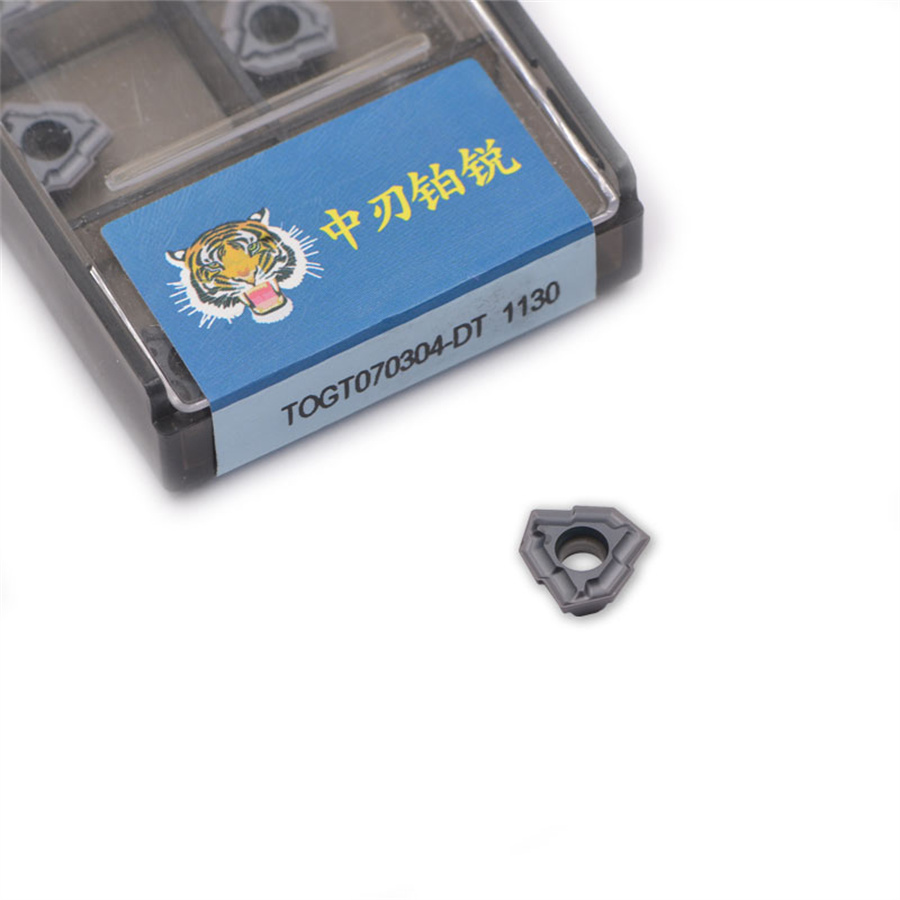

High efficiency U-drill CNC indexable inserts CNC cutting tools carbide inserts cutters blade 880-0503W05H-P-GM

Basic Information

Customized support: OEM, ODM

Place of Origin: Shandong, China

Brand Name::Zhongbian Brite

Model Number: 880-0503W05H-P-GM

Usage: For Milling

Hardness: HRC40-60

Coating:CVD/PVD/TIAN /TLIAN /TIN etc

Material:

Solid Carbide

Workpiece:Steel\ Stainless\ Cast Iron\Aluminium

Color: Black

MOQ:10 Pieces

Certification:ISO9001:2008

Payment: T/T\ Paypal\Escrow\L\Visa

1.Groove design, the cutting control is smooth, effectively reduce cutting resistance, to ensure longer tool life;

2.High quality materials;

3.Fine grinding process, we using imported production machine, automatic peripheral grinding process, higher precision, sharp wear

Why choose us

1.Advanced Equipment: Our workshop is fully equipped with spray tower, ball mill, automatic press, low pressure sintering furnace, tool grinder, CNC grinder and other equipment.

2. Cost-effective price: Cooperate with LONBOND and OERLIKON coating companies to ensure that your products are beautiful and have a longer tool life.

3.Advanced testing equipment: include hardness tester, density meter, high-power microscope, magnetic tester, metallographic tester, etc.

4.Clean and tidy environment: Managed in strict accordance with ISO9001 and 6S standard systems, scientifically and comprehensively control every link in the production process, guarantee product quality while efficient production, and provide customers with high-quality products.

5. Competitive shipping charge: Have cooperated with our shipping agent for more than 10 years. They can give us competitive price to save your money.

Coating Display

Certificates

Production Equipment

QC Equipments