Good Quality Carbide inserts Internal Deep Hole Threading Milling Inserts 16UI DE60

Basic Information

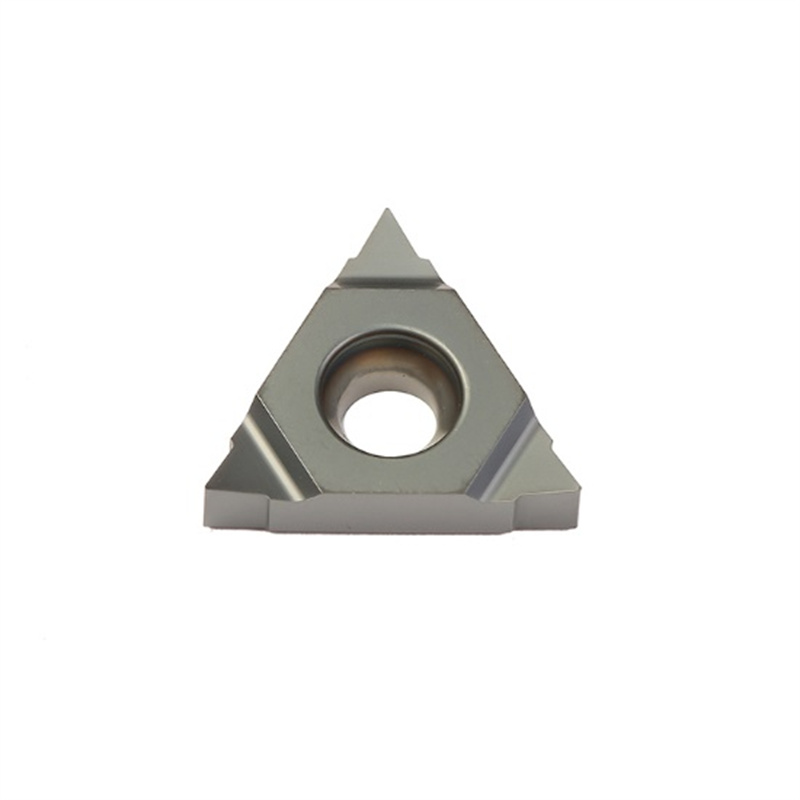

Select stable cutting tool unique cutting steel design, reduce chip emissions, suitable cutting conditions, more wear-resistant harp edge, for steel finishing

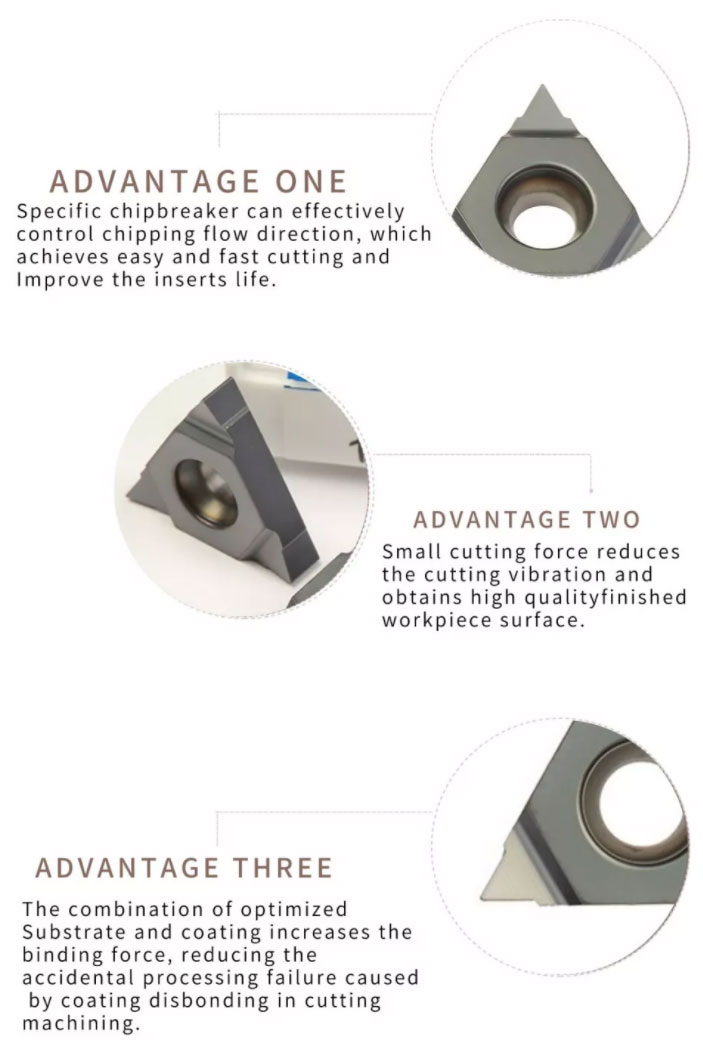

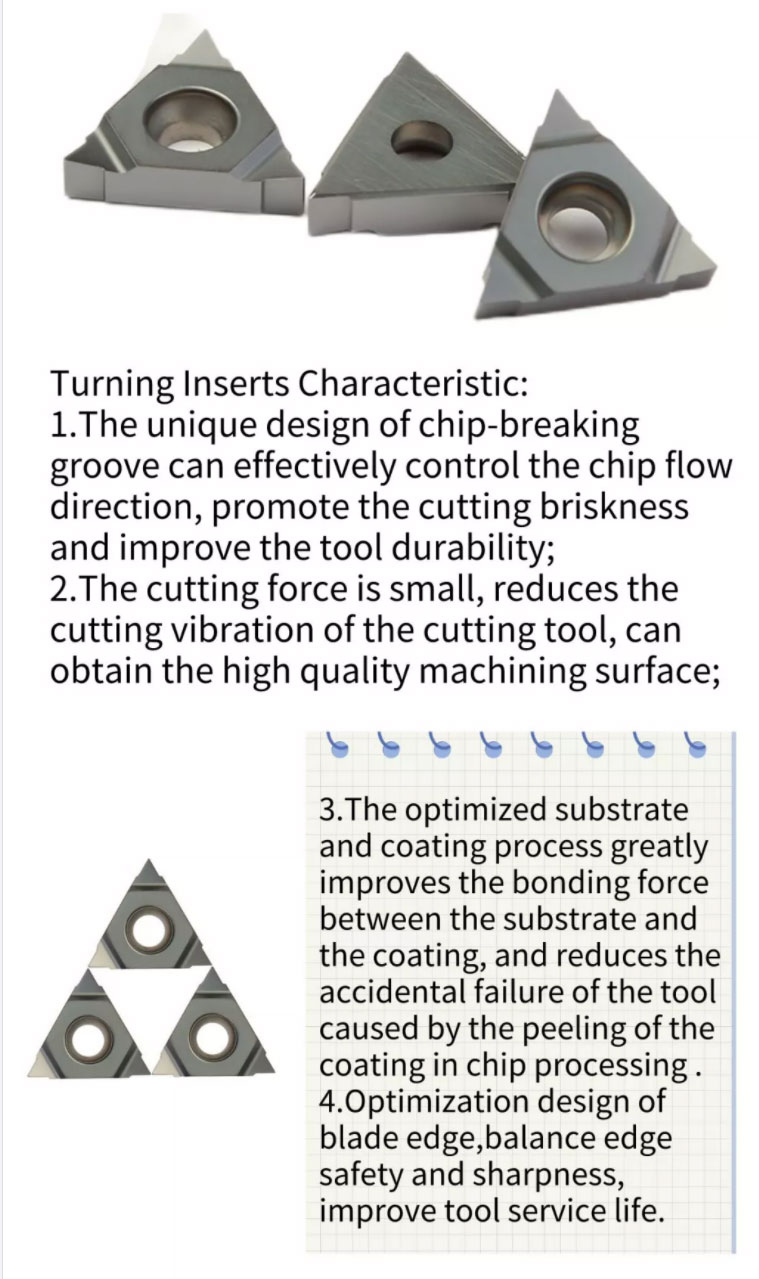

Features

1. Highly wear-resistant material specially designed for stainless steel material processing

2. Precise dimension and high accuracy

3. Strict quality management system to guarantee the consistent quality

4. Precision ground and polished, perfect cutting effect

5. PVD coating ensure the longer tool life.

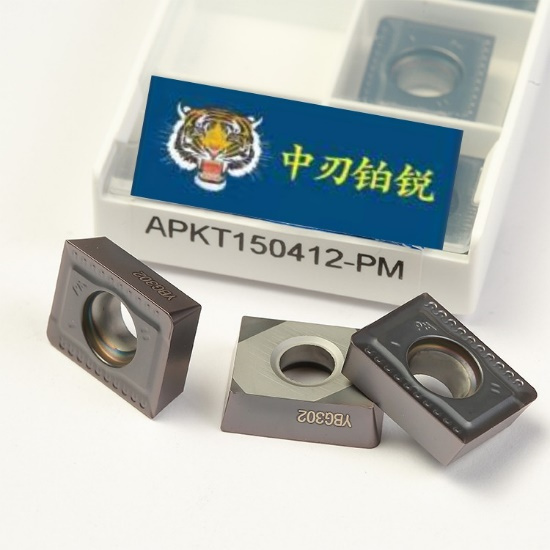

Product Specifications

Coating Display

Certificates

Production Equipment

QC Equipments

FAQ

- Who are we?

1.We are a professional CNC tool manufacturer, the company was established in the beginning of the research and development of carbide CNC blades and production. Based on years of practical experience in production, the company has accumulated rich experience in manufacturing and application. At present, the company has formed a steel parts, castings, stainless steel rough processing, semi-finishing mainly brand, has reached the domestic leading level.

2. How can we guarantee the quality?

We have our own scientific research and production team, from batching to pressing, passivation, polishing and other links have special quality inspection, in the production process of blade sampling, before mass production, we will produce a small number of samples in advance for small batch testing; The goods are still subject to final inspection.

3. What can you buy from us?

CNC cutting tools, CNC blades, carbide blades, machine tool parts, carbide drill bits, milling cutters, U-shaped drill bits, tool holders, tool handles and other accessories.

4. Why do you want to buy from us instead of other suppliers?

We are CNC tool manufacturers, independent research and development groove and advanced production technology, factory direct sales, good quality, low price, comprehensive cost performance advantage, suitable for different customer needs.