100% Original CNC cutting tools carbide inserts cutters blade 880-070406H-C-LM for Drilling

Basic Information

1. 100% original carbide powder and excellent wear resistance and toughness;

2. with super hard and smooth surface;

3. Professional chip-breaker design and provides perfect cutting performance;

4. Precise dimension, high accuracy;

5.Super long tool lifespan;

6. Customized insert design, marking, packing are available.

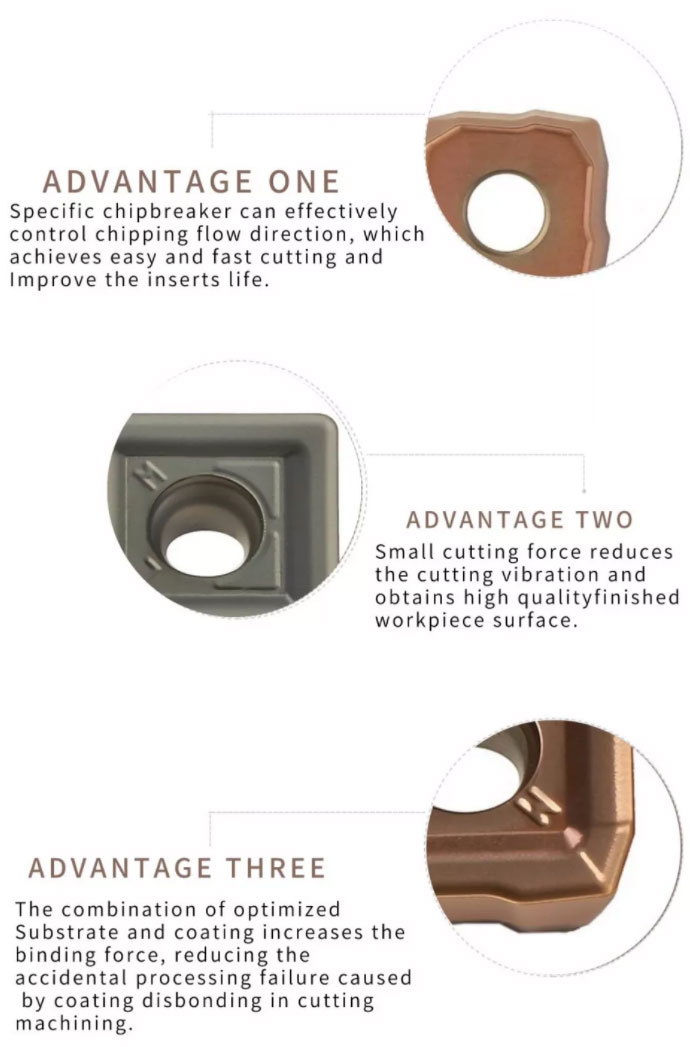

Advantages

- 1 Top quality in China. Our tungsten carbide tools inserts quality of steel cutting, cast iron cutting, stainless steel cutting inserts is equal to ZCC-CT.

- 2 Most advanced equipments. Our production equipments include "HIP-Sinter furnace, CNC high precision presser, Five axis machining center, CVD coating furnace, PVD coating furnace."

- 3 Strong technical support. Our senior engineers are engaged in cutting tools industry for decades, we provide excellent service in grade selection, cuting data recommendation, and solution for your tools.

- 4 Reputation among our customers. We have big customers of carbide inserts in Europe, such as Germany, Italy, UK, Poland, Czech, Ukraine. In South America, such as Brazil, Peru. And in Asia, such as India, Iran.

Product Specifications

Our Service

Pre-sale Service:

We have professional sales staff, who can get to know the details about your needs and offer feedback.

Sales Service:

After the signing of the contract, our professional sales staff will communicate and work on the production schedules or your change of demand.

After-sale Service:

We will arrange the returning and changing of the products timely if they have quality problems. At the same time, return visits will be made regularly to know service condition of our products.

Coating Display

Certificates

Production Equipment

QC Equipments

FAQ

Q: 1. Are you a trading company or manufacturer?

A: Our company is a professional producer with more than 10 years experience in this field.

Q: 2. Can you produce Special Carbide Tools?

A: Yes, we can. We can produce according to your drawing or sample.

Q: 3. What's your MOQ?

A: 10 pieces.

Q: 4. How long is the delivery time?

A: Stock product: We have stock for some regular product, we can send them immediately once order confirmed. For Non-stock product: Within 10-15 days

Q: 5. Do you provide samples?

A: Yes, we can offer samples for testing as support.