Q: What tools need to be sharpened?

A: Most of the tools can be trimmed, in the production design to take into account the subsequent tool grinding; Of course, on this basis, tool grinding should also take into account the overall cost and benefit; For most of the relatively low price, the tool with relatively high grinding cost can be scrapped directly and abandoned because its own added value is not high; For some forming tools, because the size after grinding will be small and affect the use, it can not be grinding; When some standard diameter taps, milling cutters, drill bits need to be repaired, when the overall cost is relatively high, you need to consider the tool grinding, in order to reduce production costs, reduce resource consumption of low-carbon green behavior.

Q: What are the key aspects of tool grinding?

A: When the blunt edge line is cut off, and then grind out a new edge on the more complete matrix; For hole machining drilling tools, it is necessary to consider the damage of the guide part before grinding; When the cutting edge is worn normally and evenly, repair grinding can be carried out directly. When the edge of the tool is relatively not very serious, the tool can be cut off the worn or broken parts and then grinding;

Q: Can the tool be coated again after grinding?

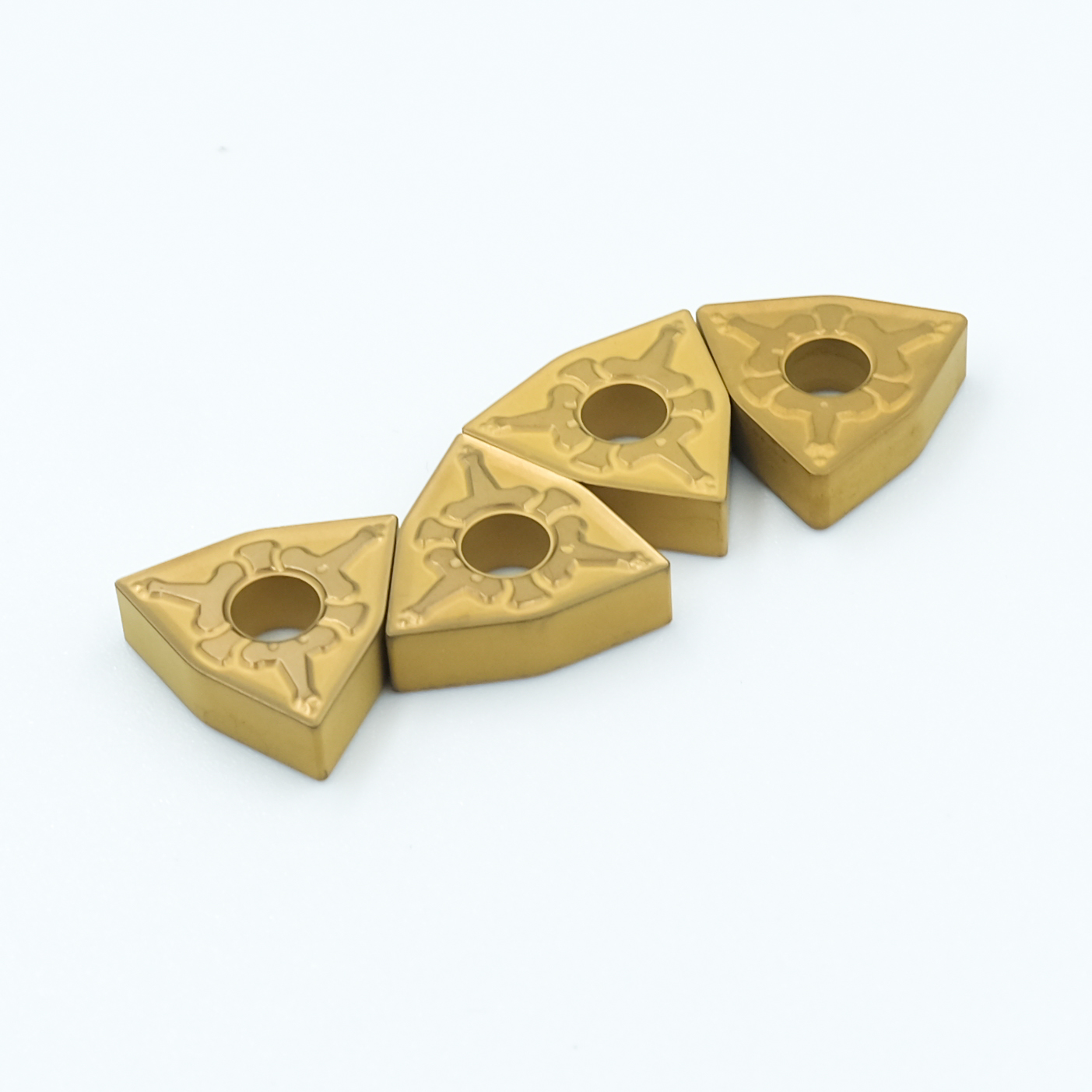

A: The new cutting edge of Shuo tool is produced after grinding the back tool face (and the front tool face); Select suitable front and rear angles and cutting edge treatment; According to customer requirements can be repaired tool accuracy requirements to choose whether to need coating.

Post time: Dec-11-2023