Compared with traditional inserts, the new type of milling inserts have achieved significant performance improvements in many aspects, mainly reflected in the following key areas:

1. Material improvement

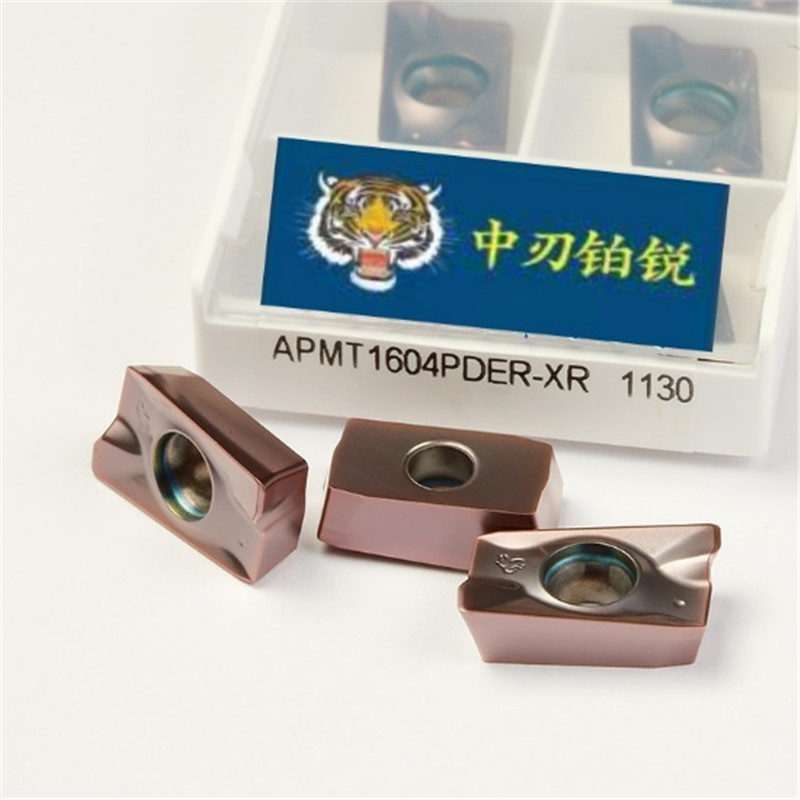

Modern milling inserts employ more advanced materials, such as ultrafine-grained cemented carbide, ceramics, and cubic boron nitride (CBN), etc. These materials have higher hardness and wear resistance, which can maintain the sharpness of the cutting edge during high-speed cutting, reduce wear, thereby extending the service life of the tool and improving processing efficiency.

2. Optimization of cutting edge design

The new type of blade features a more refined design of the cutting edge, adopting innovative designs such as wavy edges and chip distribution grooves, which help control the formation and discharge of chips, reduce cutting force and cutting temperature, minimize workpiece deformation and surface damage, and is particularly suitable for precision machining.

3. Progress in coating technology

The development of coating technology is one of the important factors for the performance improvement of new types of blades. Wear-resistant and heat-resistant coatings applied through methods such as physical vapor deposition (PVD) or chemical vapor deposition (CVD), such as TiAlN (titanium aluminum nitride) and CrN (chromium nitride), can significantly enhance the wear resistance of the cutting blade, improve its coefficient of friction, and reduce heat accumulation during the cutting process.

4. Enhanced multi-functionality and adaptability

To meet the demands of different materials and processing conditions, the new type of milling inserts have been designed to be more functional and adaptable. For example, some blades can work efficiently under dry or minimal lubrication conditions, which is both environmentally friendly and can reduce production costs. There are also some blades that have been specifically optimized for difficult-to-machine materials, such as high-temperature alloys and titanium alloys.

5. Improve processing accuracy and surface quality

Thanks to the improvements in all the above aspects, the new type of milling inserts can provide higher processing accuracy and better surface quality. Both dimensional accuracy and shape accuracy have been significantly improved compared with traditional blades. In addition, due to the more stable cutting process and reduced vibration, it further promotes the improvement of surface finish.

In conclusion, the new type of milling inserts, with the advancement of materials science, innovative design concepts, advanced coating technology and stronger adaptability, have not only significantly improved processing efficiency and product quality, but also provided strong support for the manufacturing industry to develop to a higher level. With the continuous advancement of technology, the performance of milling inserts will continue to be improved and perfected in the future.

Compared with traditional inserts, the new type of milling inserts have achieved significant performance improvements in many aspects, mainly reflected in the following key areas:

1. Material improvement

Modern milling inserts employ more advanced materials, such as ultrafine-grained cemented carbide, ceramics, and cubic boron nitride (CBN), etc. These materials have higher hardness and wear resistance, which can maintain the sharpness of the cutting edge during high-speed cutting, reduce wear, thereby extending the service life of the tool and improving processing efficiency.

2. Optimization of cutting edge design

The new type of blade features a more refined design of the cutting edge, adopting innovative designs such as wavy edges and chip distribution grooves, which help control the formation and discharge of chips, reduce cutting force and cutting temperature, minimize workpiece deformation and surface damage, and is particularly suitable for precision machining.

3. Progress in coating technology

The development of coating technology is one of the important factors for the performance improvement of new types of blades. Wear-resistant and heat-resistant coatings applied through methods such as physical vapor deposition (PVD) or chemical vapor deposition (CVD), such as TiAlN (titanium aluminum nitride) and CrN (chromium nitride), can significantly enhance the wear resistance of the cutting blade, improve its coefficient of friction, and reduce heat accumulation during the cutting process.

4. Enhanced multi-functionality and adaptability

To meet the demands of different materials and processing conditions, the new type of milling inserts have been designed to be more functional and adaptable. For example, some blades can work efficiently under dry or minimal lubrication conditions, which is both environmentally friendly and can reduce production costs. There are also some blades that have been specifically optimized for difficult-to-machine materials, such as high-temperature alloys and titanium alloys.

5. Improve processing accuracy and surface quality

Thanks to the improvements in all the above aspects, the new type of milling inserts can provide higher processing accuracy and better surface quality. Both dimensional accuracy and shape accuracy have been significantly improved compared with traditional blades. In addition, due to the more stable cutting process and reduced vibration, it further promotes the improvement of surface finish.

In conclusion, the new type of milling inserts, with the advancement of materials science, innovative design concepts, advanced coating technology and stronger adaptability, have not only significantly improved processing efficiency and product quality, but also provided strong support for the manufacturing industry to develop to a higher level. With the continuous advancement of technology, the performance of milling inserts will continue to be improved and perfected in the future.

Post time: May-19-2025