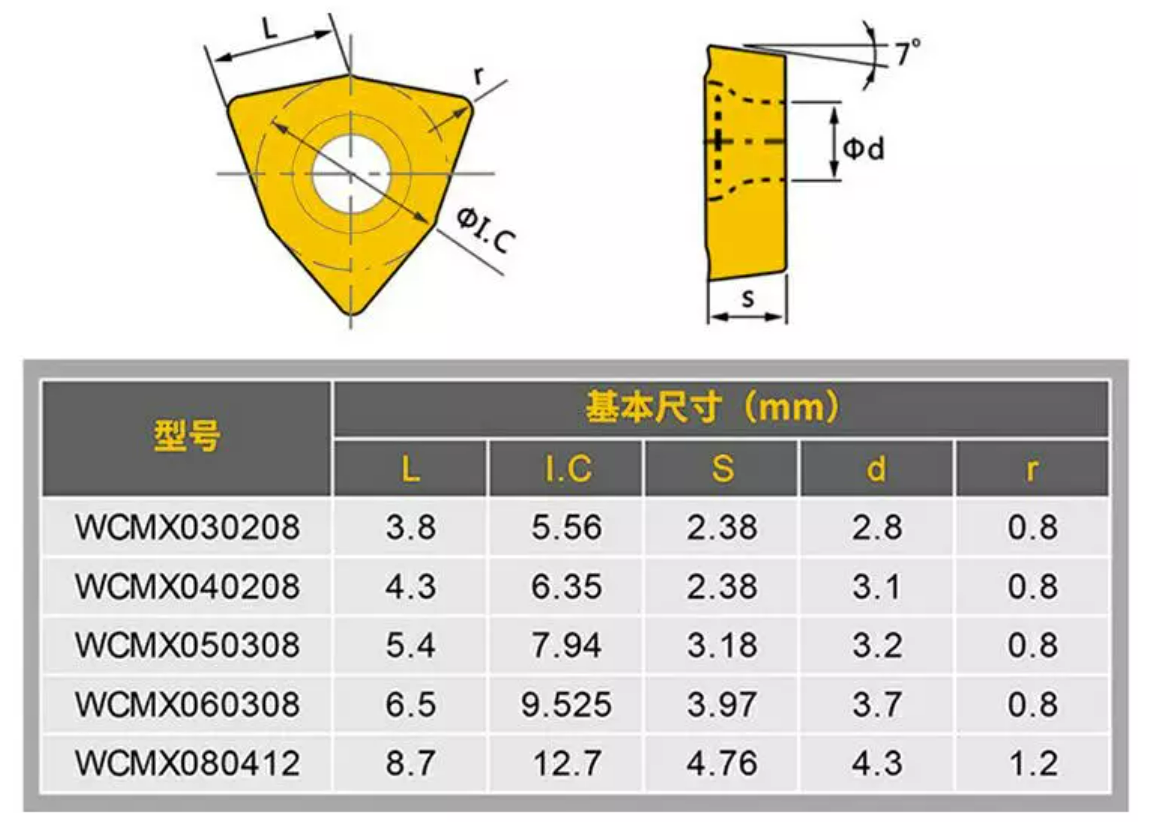

WCMX050308 Cnc Cutting Tools Indexble Carbide U Drilling Cutter Inserts For Hole Making

Major Products

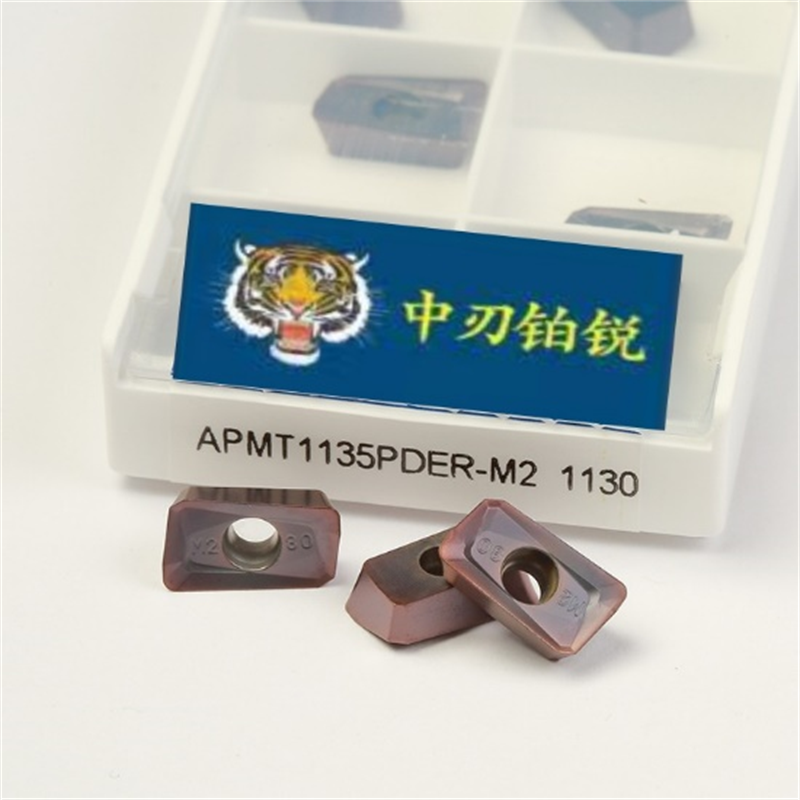

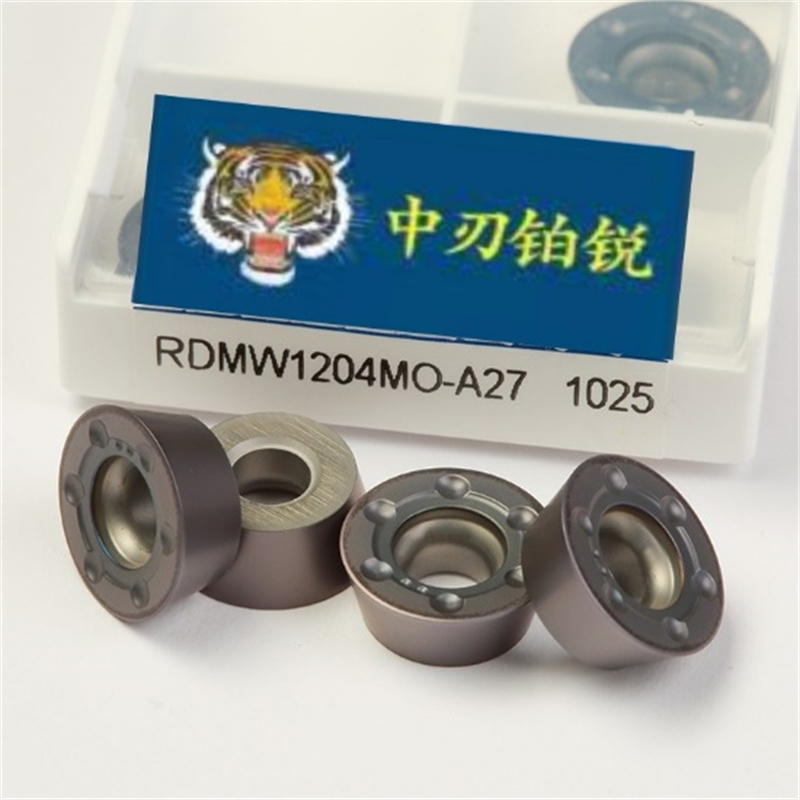

Milling : APMT APKT RDMT RPMT LNMU BLMP SEKT SDMT SOMT SEKN SEEN SPKN TPKN TPKR TPMR 3PKT WNMU SNMU ONMU AOMT JDMT R390 BDMT

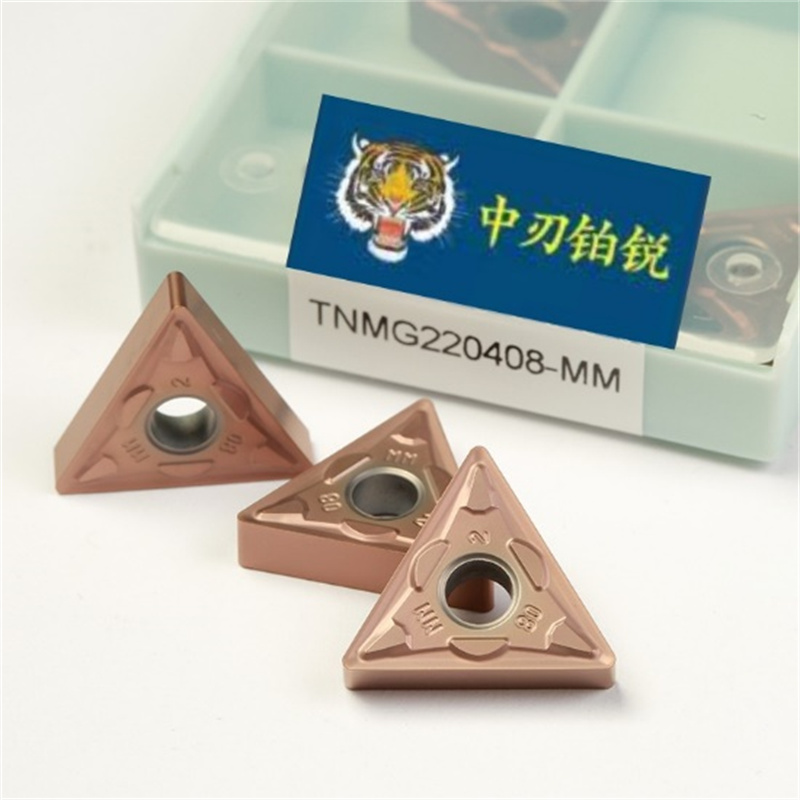

Turning: CNMG CCMT SNMG SCMT WNMG TNMG TCMT DCMT DNMG VNMG VBMT KNUX

Grooving : MGMN MRMN N151 N123 ZTFD TDC2 TDC3 TDC4

For aluminum : APGT APKT CCGT DCGT VCGT RCGT SCGT SEHT TCGT ZTED

Threading : 11IR 11ER 16ER 16IR 22ER 22IR

U Drill: SPMT WCMX WCMT

Cast Iron: CNMA DNMA SNMA TNMA VNMA WNMA

Our carbide cutting insert Select turning tools withstable unique cutting steel design, reduce chip emissions, suitable cutting conditions, more wear-resistant harp edge, easy to finish steel

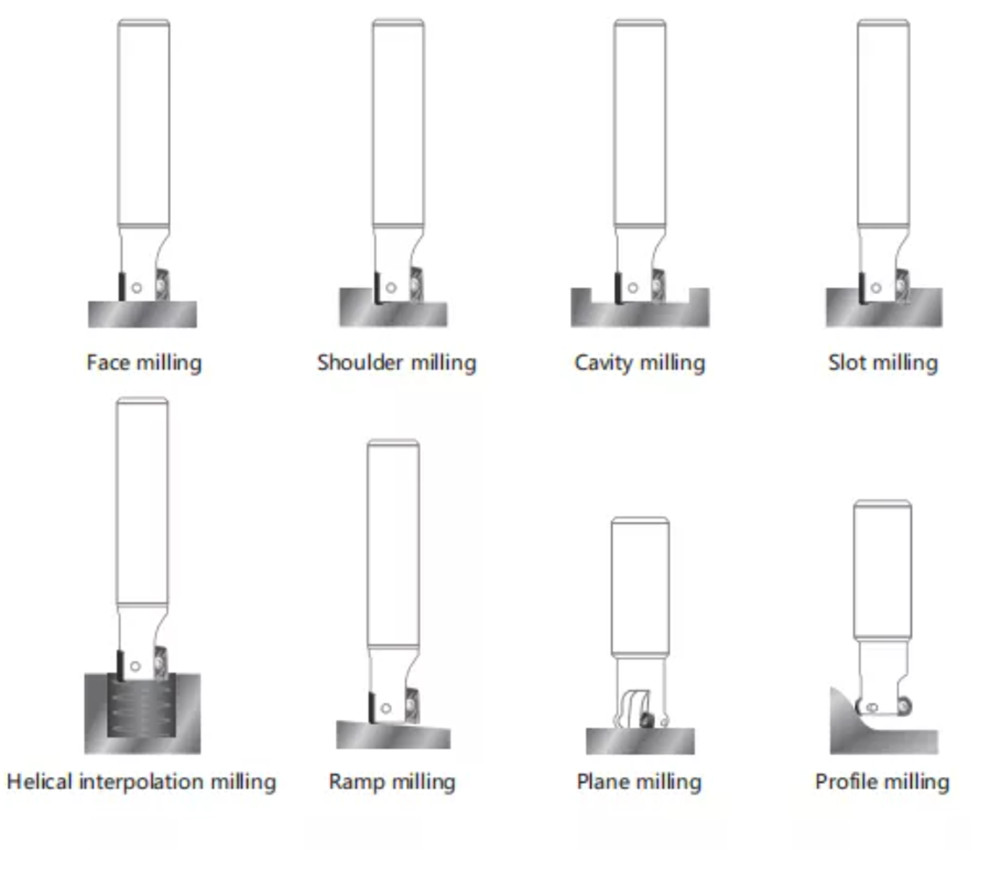

Application

Main Application: For processing carbon steel, cast iron, stainless steel

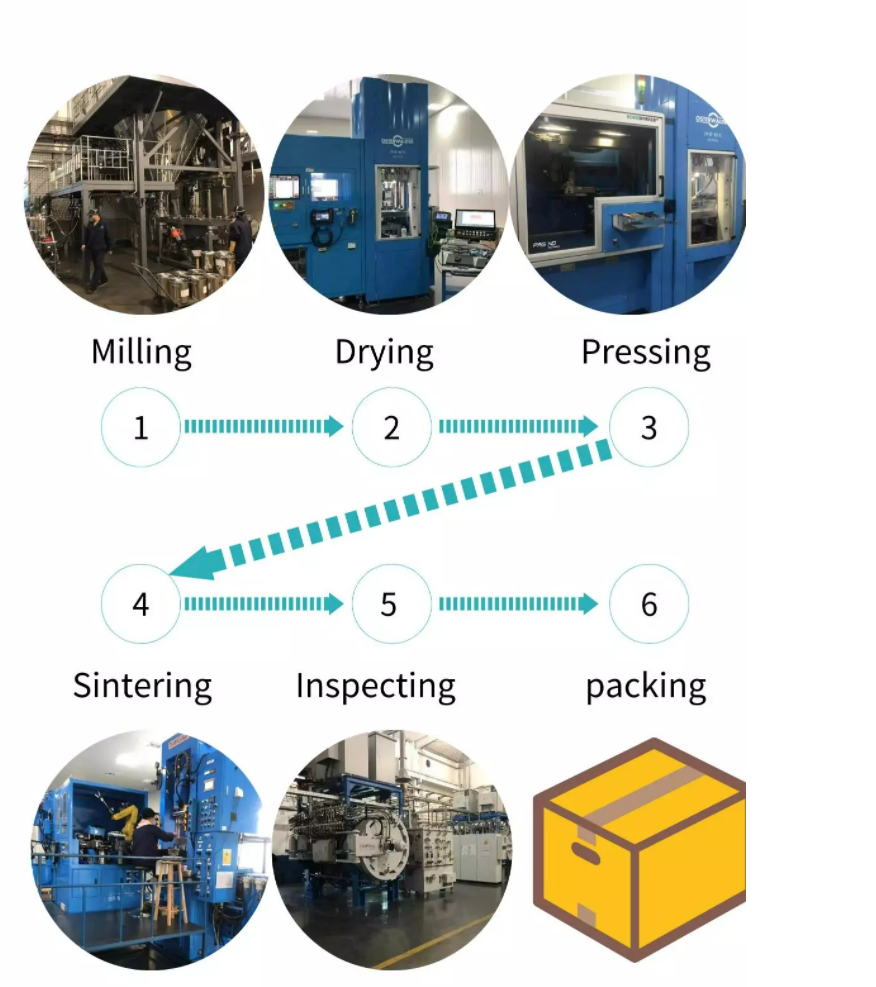

Production process

Product Specifications

Whether you need a general milling or heavy milling inserts for face milling, shoulder milling, slot milling, profile milling, or ramp milling, or even milling higher requirements of surface smoothness, Our engineer can turn your design into a milling insert in just days.

Coating Display

Package And Delivery

100% anti-walter package.

One plastic pipe pack one piece,10 pcs per group.

Put goods enclosed with air bubble paper into box.

Other package is accepted according to customer's requirement.

Orders processed timely after the payment verification. we have many shipping ways, like DHL, Fedex, EMS and so on, will choose the best one for you.

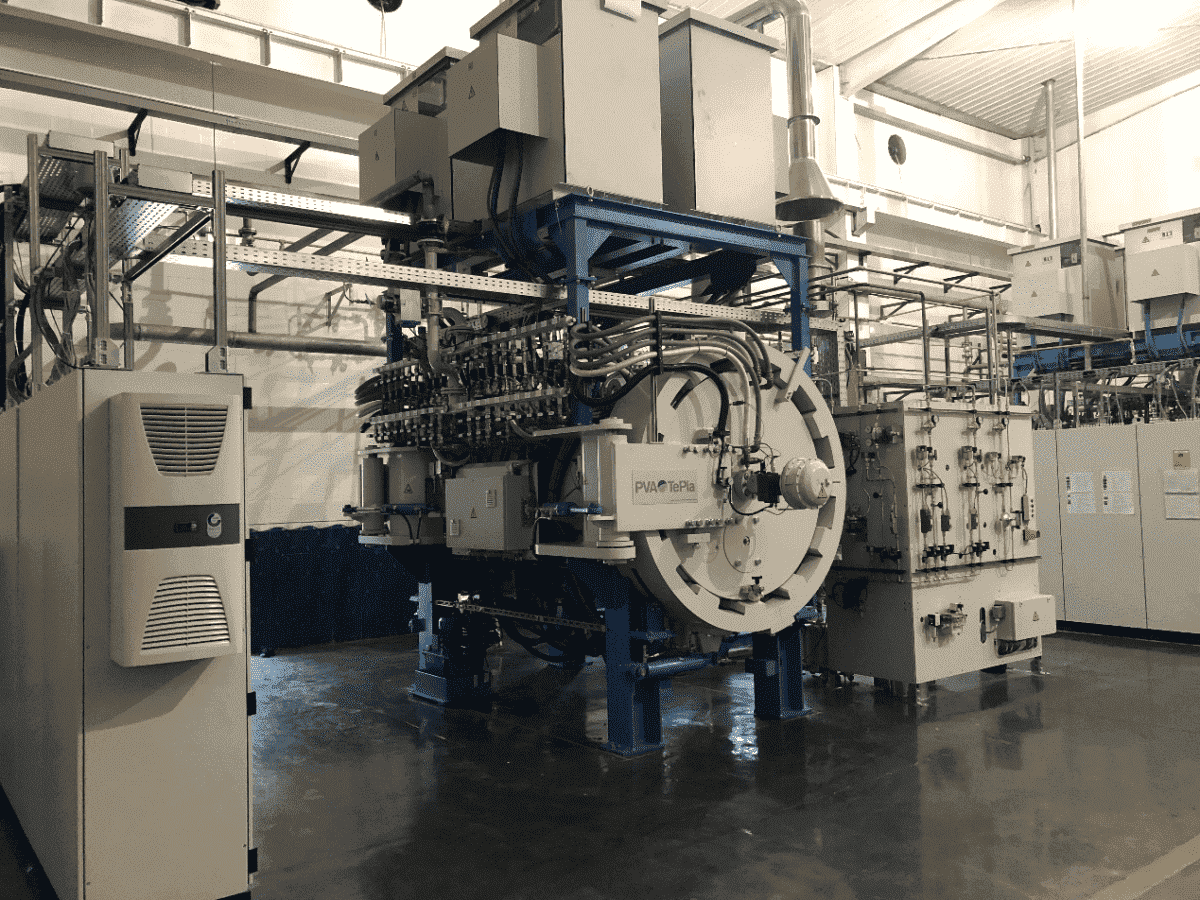

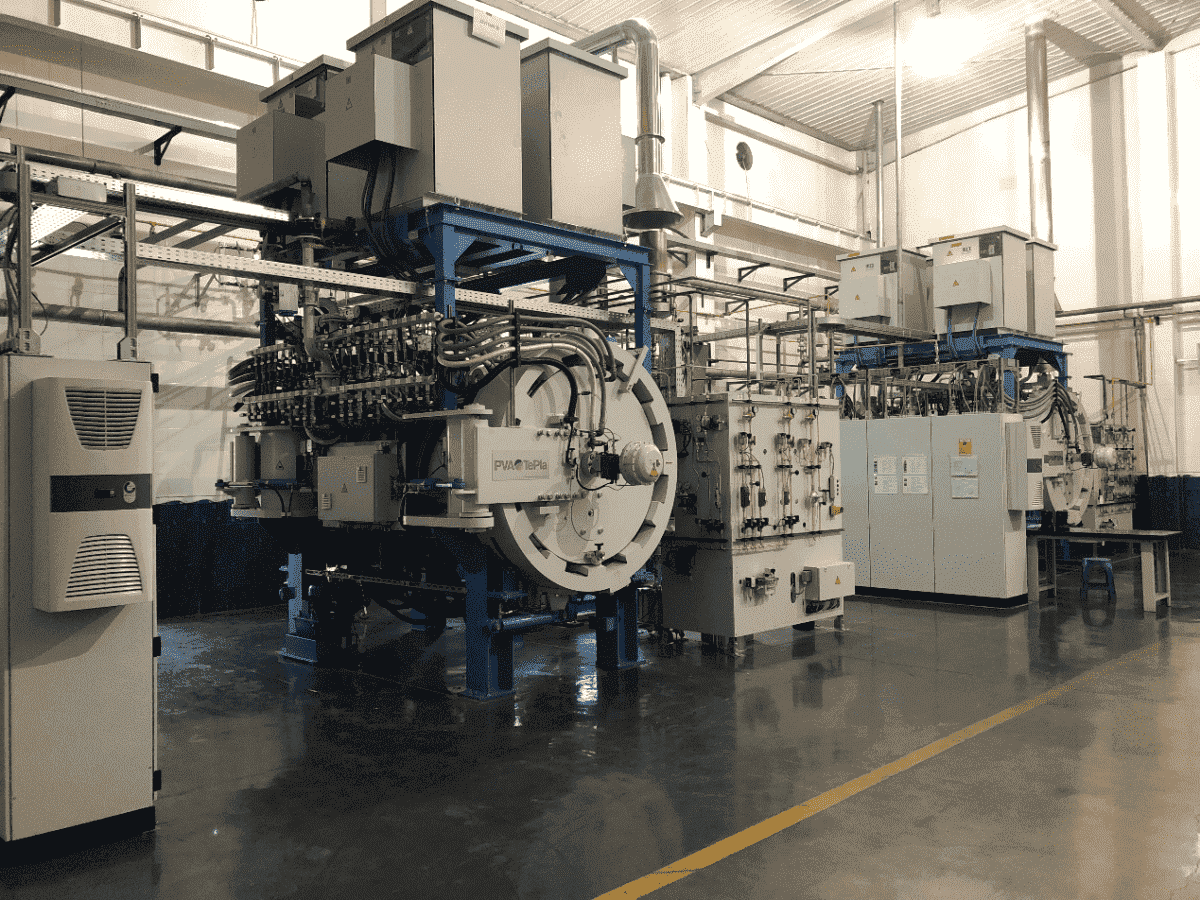

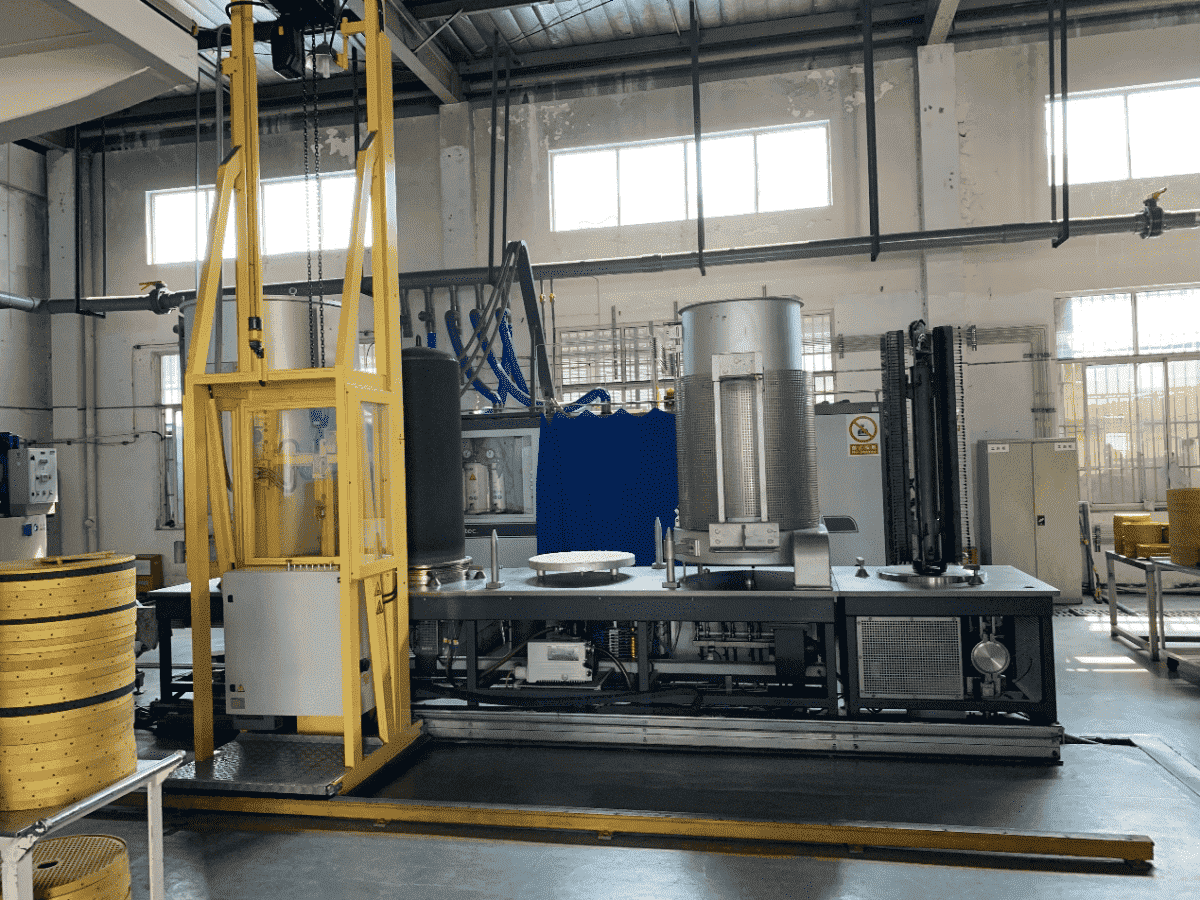

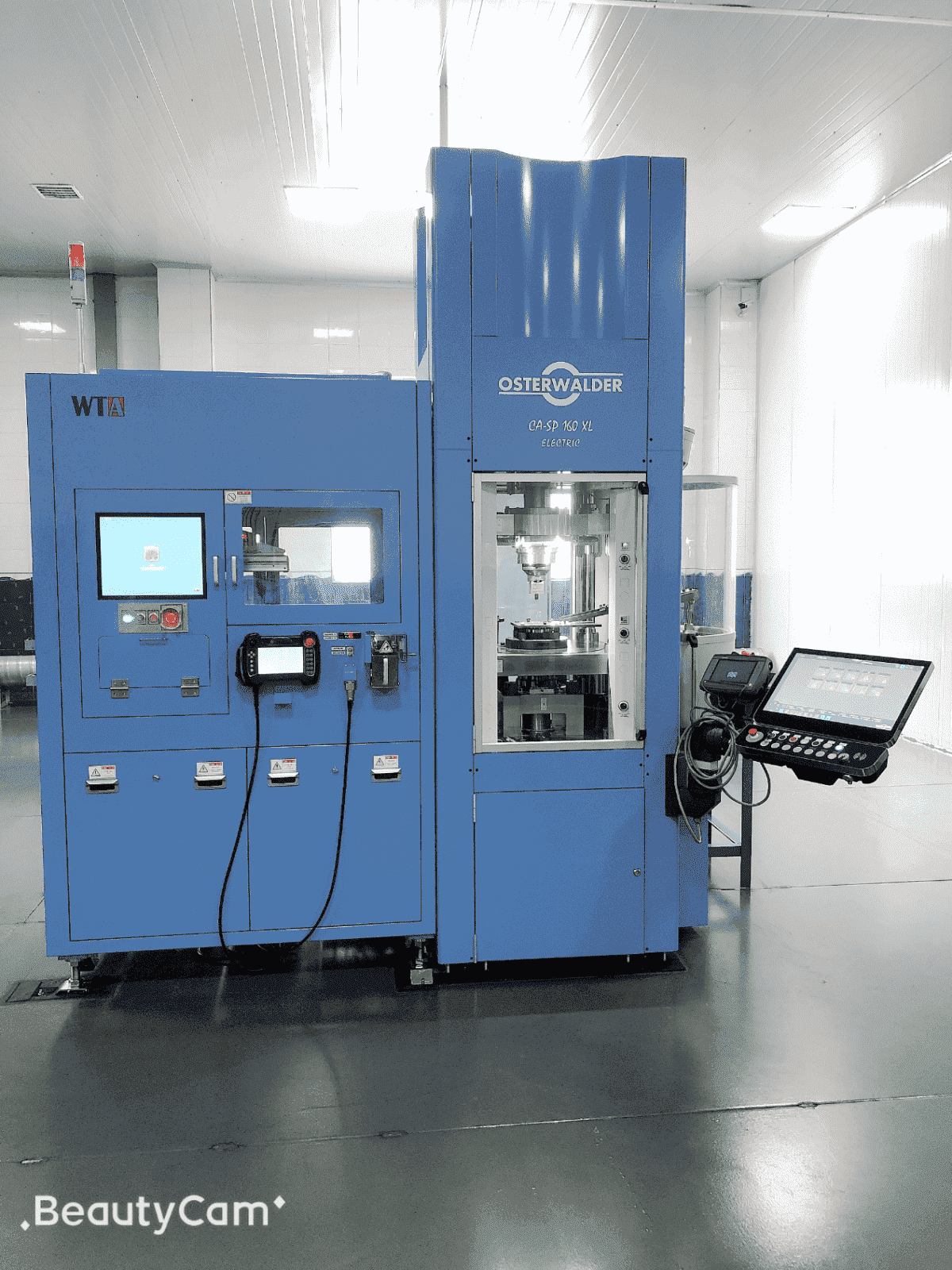

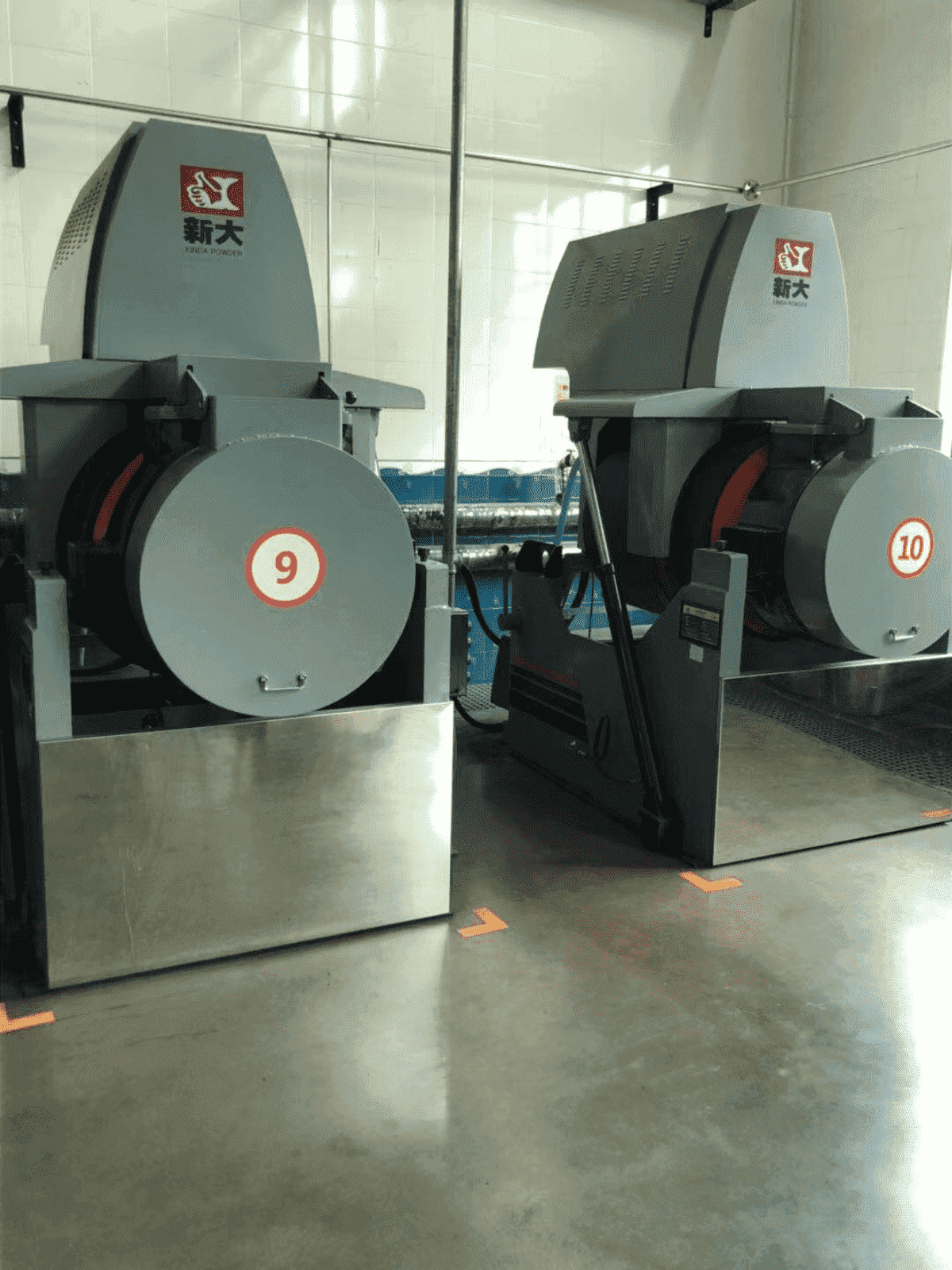

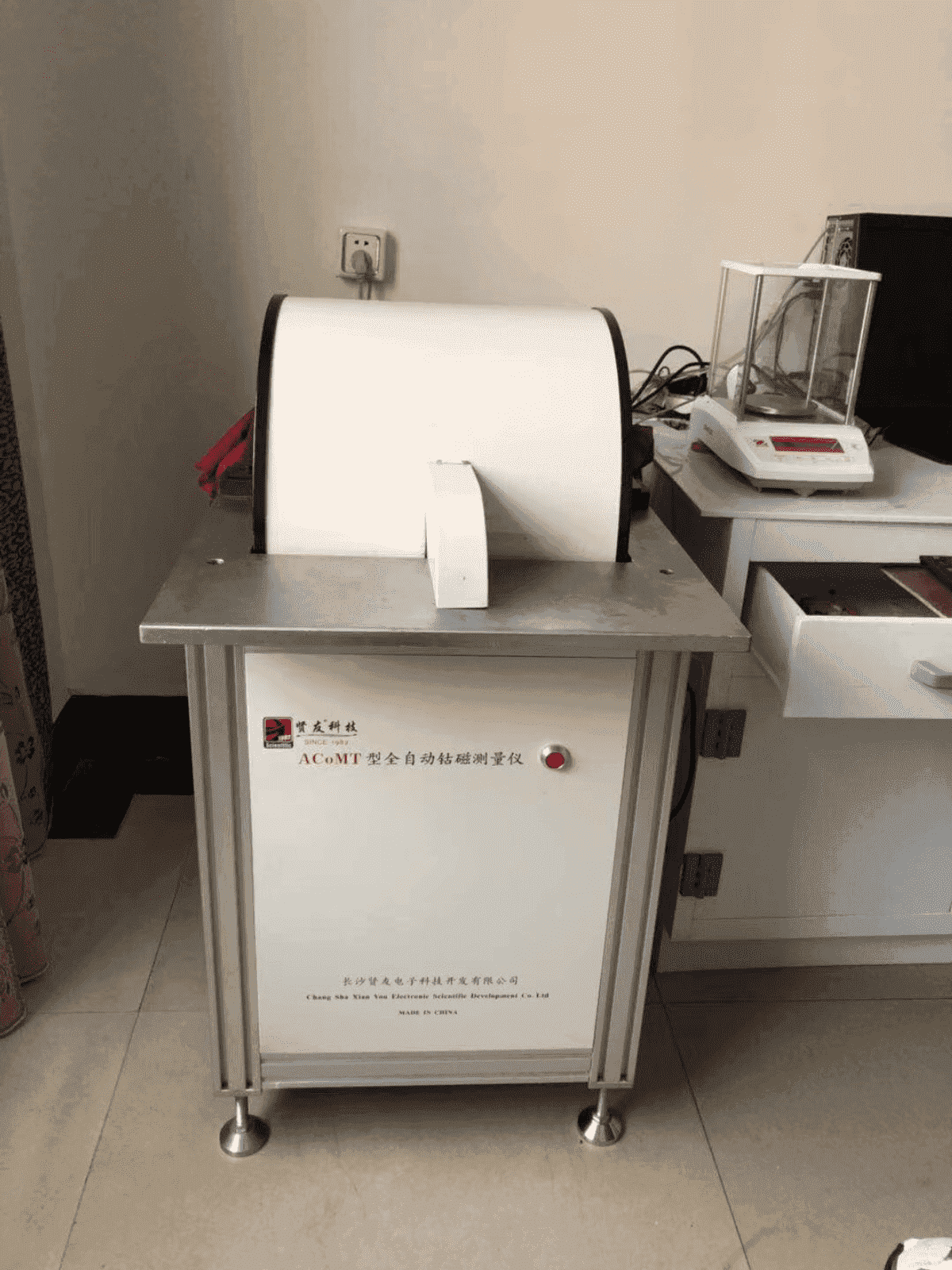

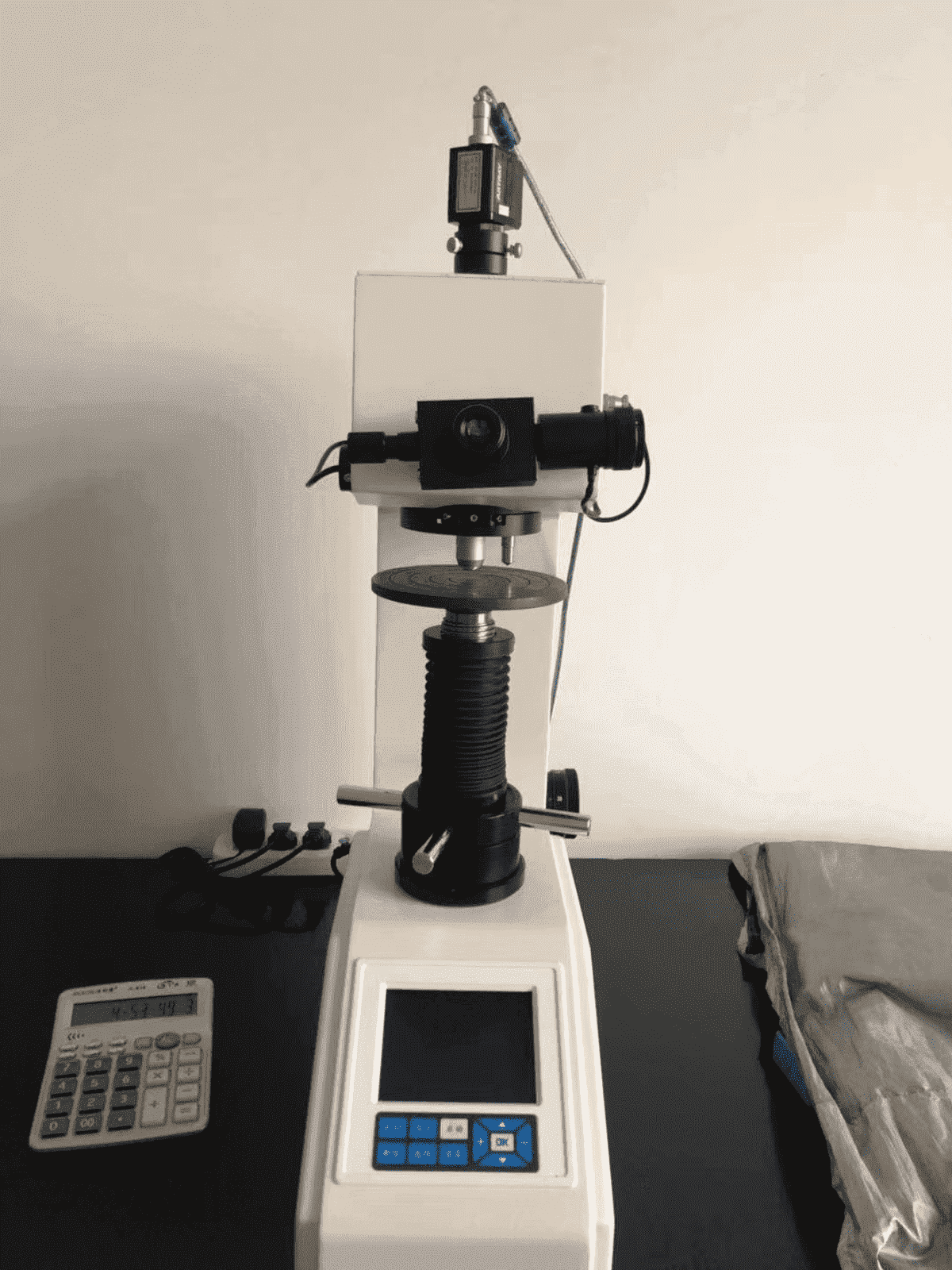

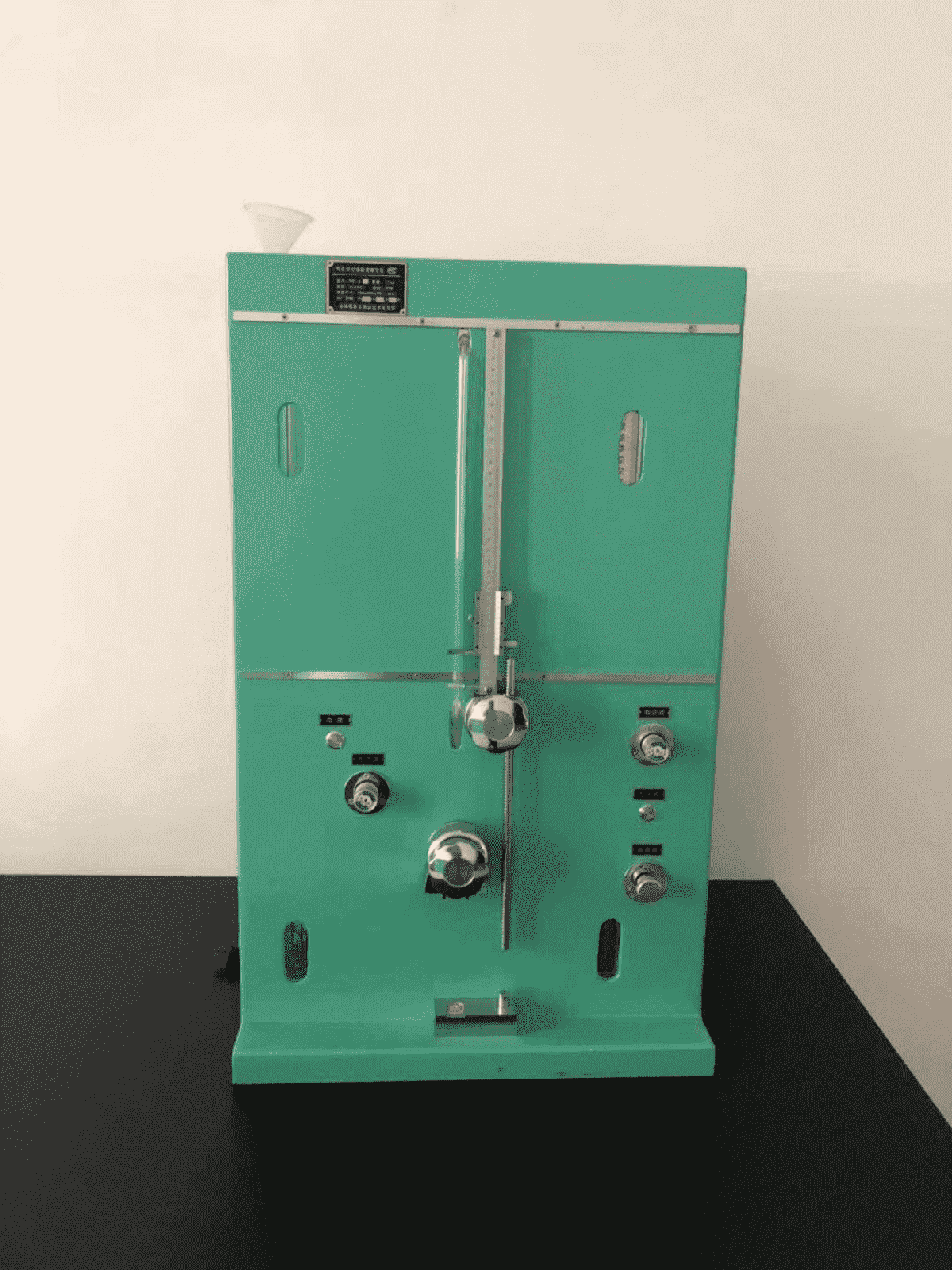

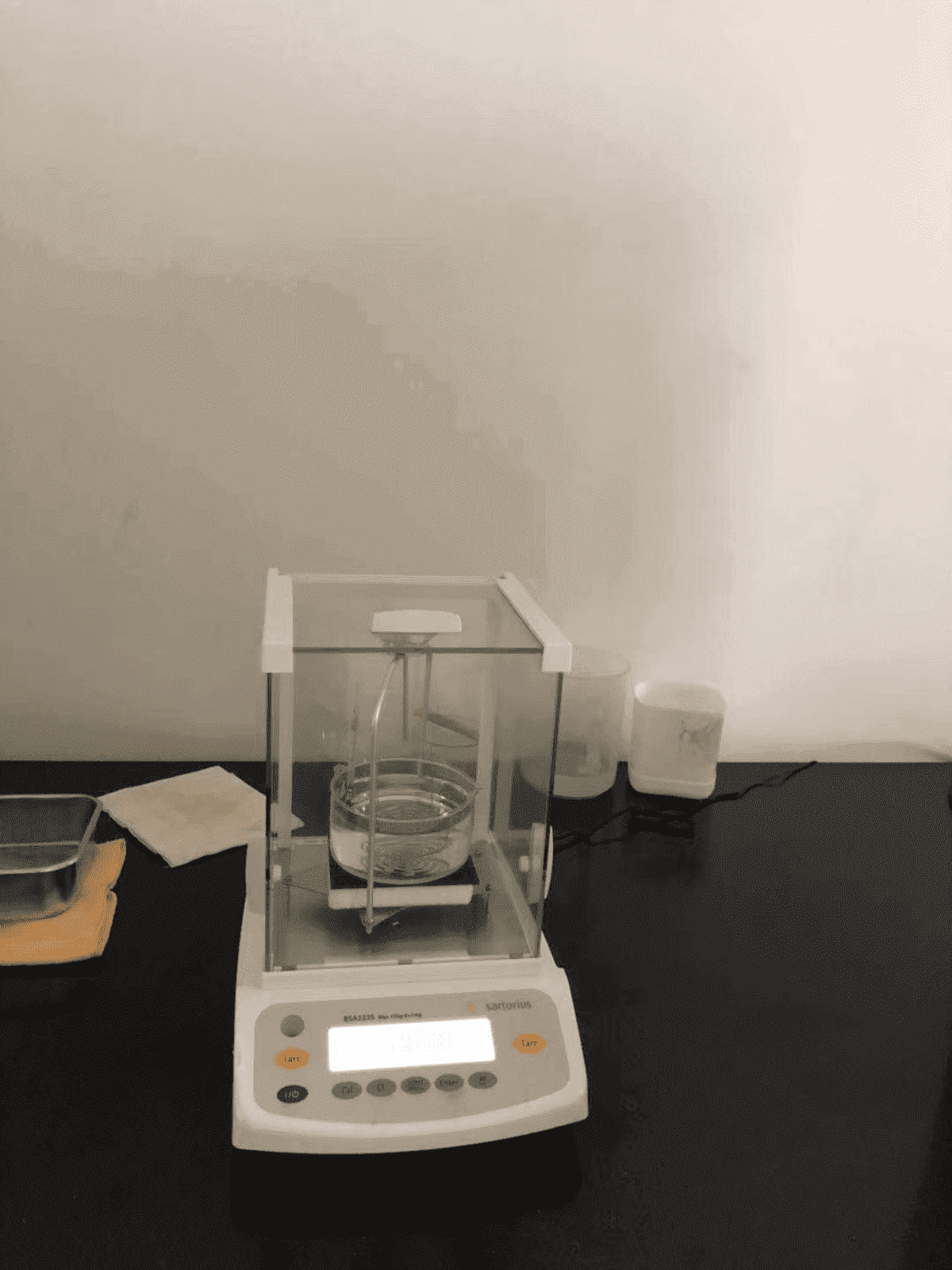

Production Equipment

QC Equipments

Certificates

Advantages

1.Good thermal conductivity and impact resistance, ensure a good surface

Material of Products:

2.Highly wear-resistant material specially designed for stainless steel material processing

3.Surface of Products: with smooth surface

4.Size of Products: Precise dimension and high accuracy

5.Lifetime of Products: Super long lifetime

6.OEM and ODM: Customized insert design, marking, packing are available.

FAQ

Q1: How long is your delivery time?

A: Uncoating with 10-15days. Coating with 20-25days.

Q2: Do you provide samples ? is it free or extra ?

A: Yes, we could provide samples with free.

Q3: What is your terms of payment ?

A: 30% payment in advance, 70% remit before shipment.

Q4: How about your MOQ?

A: 10pcs with one box.

Q5: How about your after sales service?

A: After sales service is sharpen and refurbish, the service person is online 24 hours.