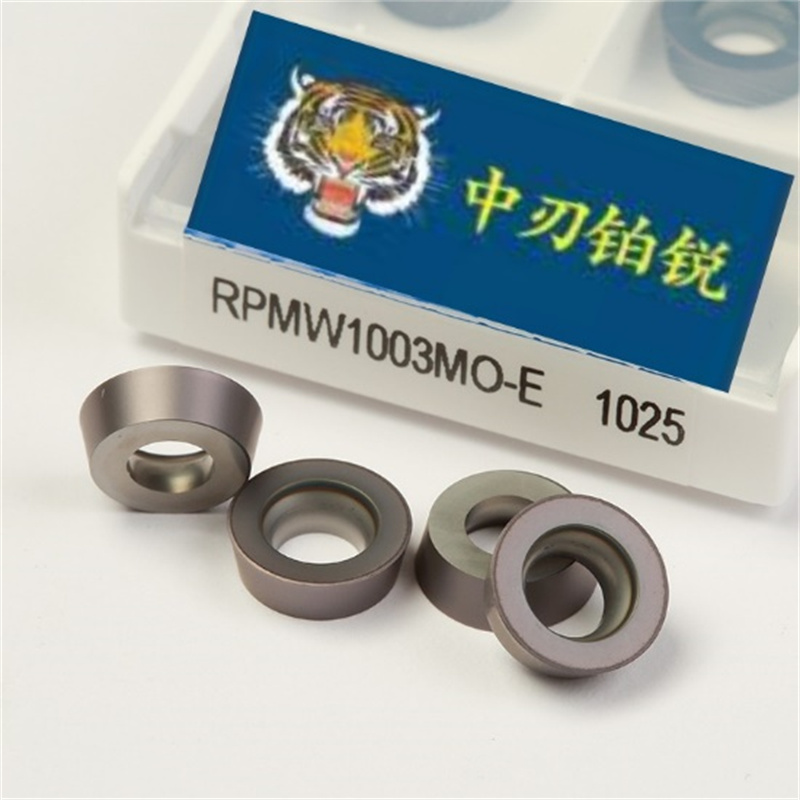

High Quality MITSUBISHI Carbide CNC Milling Inserts Milling Cutters RPMW

Basic Information

Customized support: OEM, ODM

Place of Origin: Shandong, China

Brand Name::Zhongbian Brite

Model Number: RPMW

Usage: For Milling

Hardness: HRC40-60

Coating:CVD/PVD/TIAN /TLIAN /TIN etc

Material:

Solid Carbide

Workpiece:Steel\ Stainless\ Cast Iron\Aluminium

Color: Black

MOQ:10 Pieces

Certification:ISO9001:2008

Payment:T/T\ Paypal\Escrow\L\Visa

Application

Main Application: For processing carbon steel, cast iron, stainless steel

Package and Shipment:

100% anti-water package.

One plastic pipe pack one piece,10 pcs per group.

Put goods enclosed with air bubble paper into box.

Other package is accepted according to customer's requirement.

1.If the quantity of order is not very big,we could send them to you by express delivery. such as TNT,DHL,UPS or EMS etc.

2.If order is big ,we will suggest you use Air Shipping or Sea Shipping through your designated Freight forwarder agent. our long-term cooperated agents ate also available.

3:About shipping time ups: about 7-10 working days FedEx: about 4-8 working days DHL: about 3-5 working days By sea: about 30 working days.

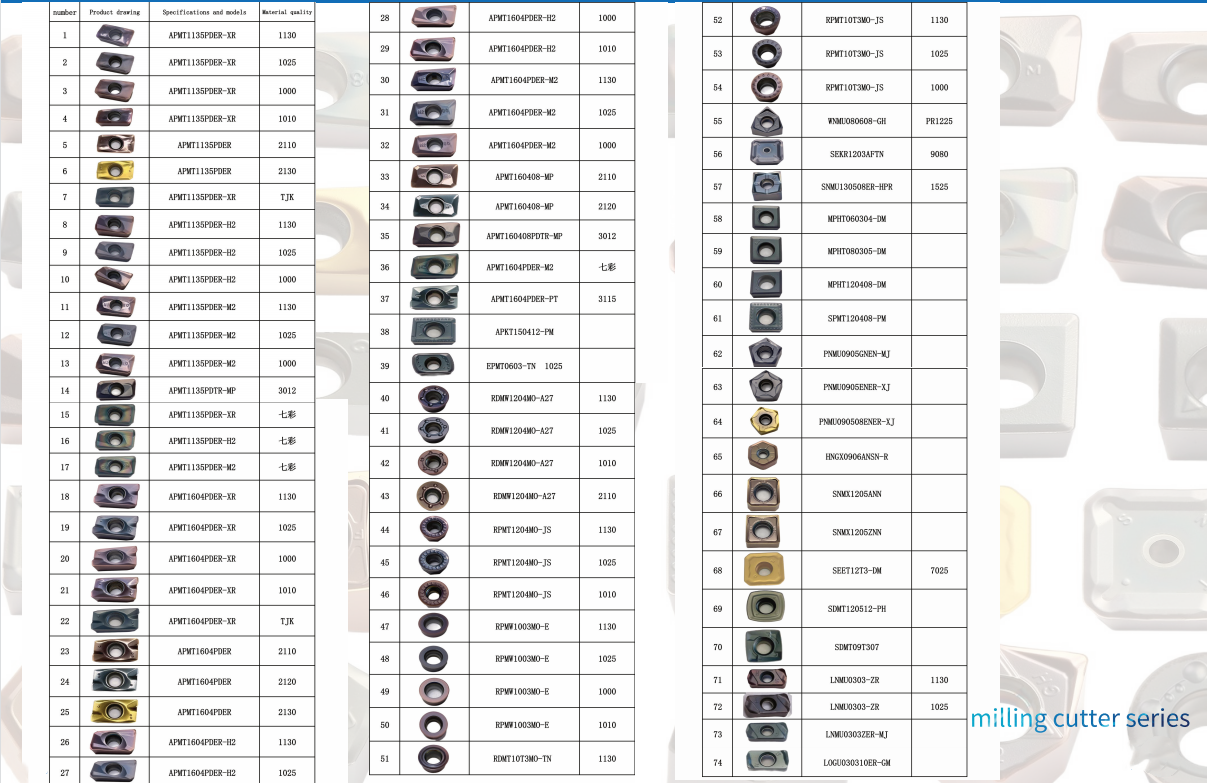

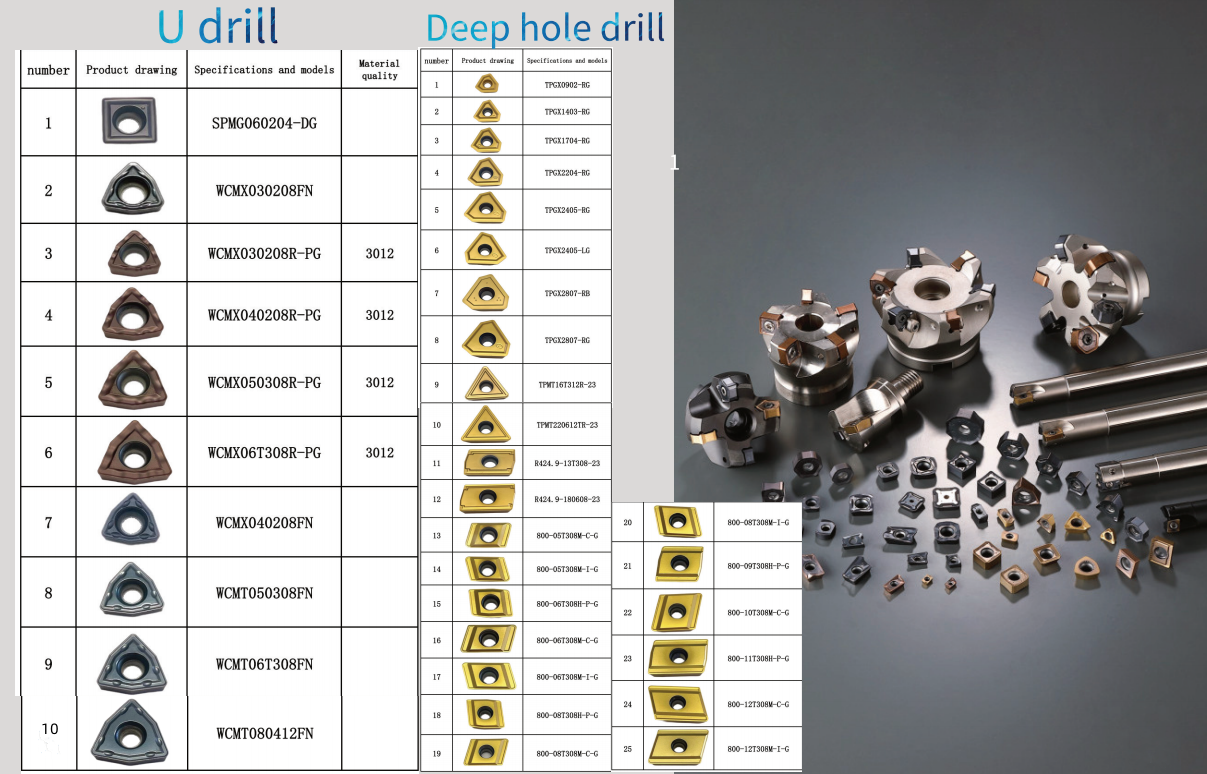

Coating Display

Certificates

Production Equipment

QC Equipments

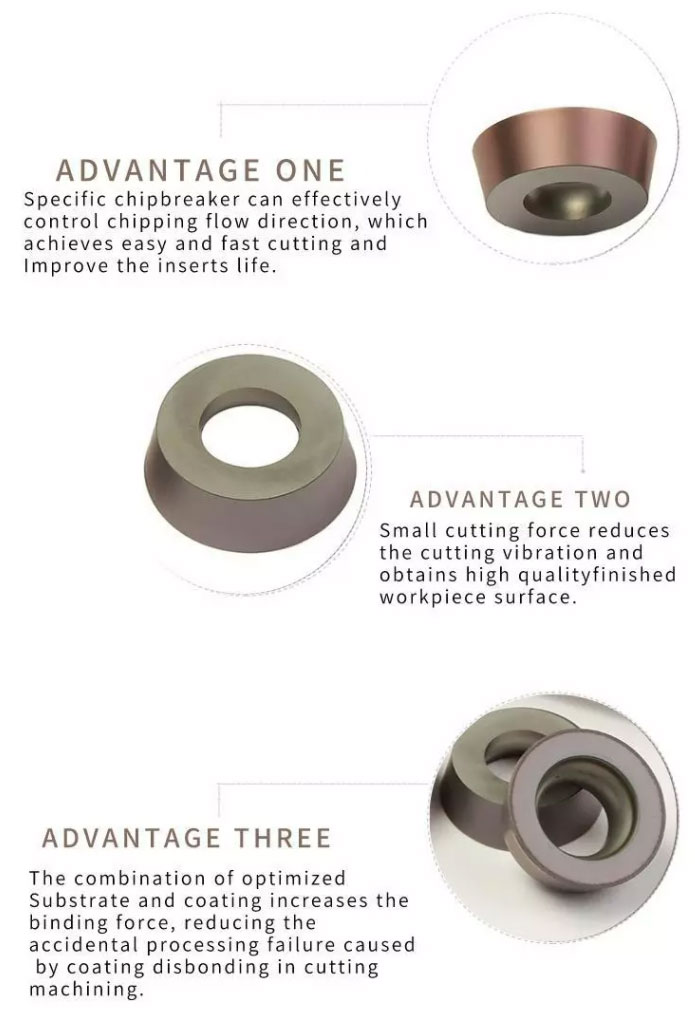

Features

1. Highly wear-resistant material specially designed for stainless steel material processing

2. Precise dimension and high accuracy

3. Strict quality management system to guarantee the consistent quality

4. Precision ground and polished, perfect cutting effect

5. PVD coating ensure the longer tool life.