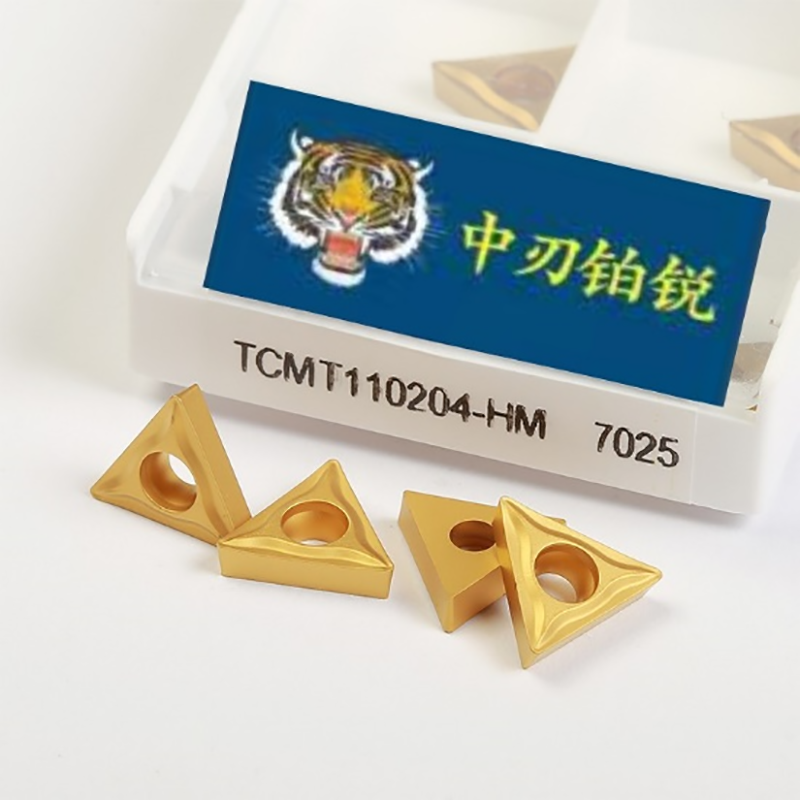

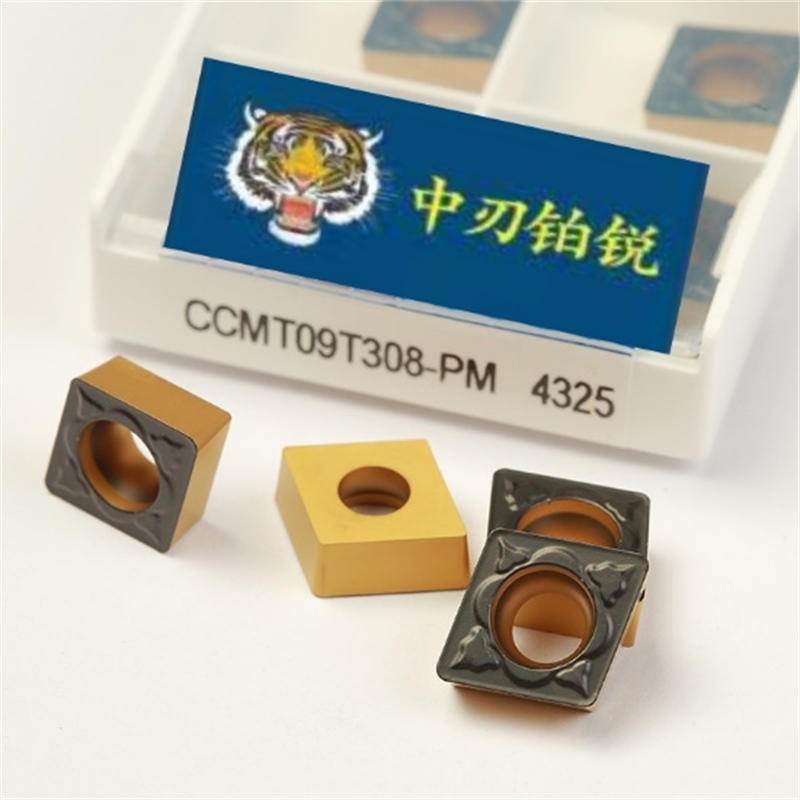

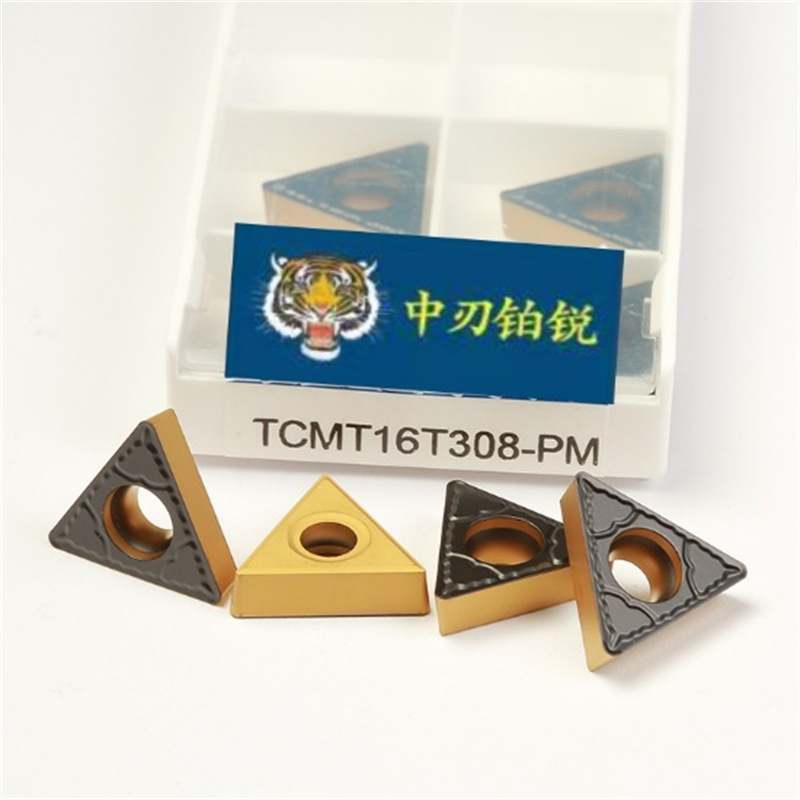

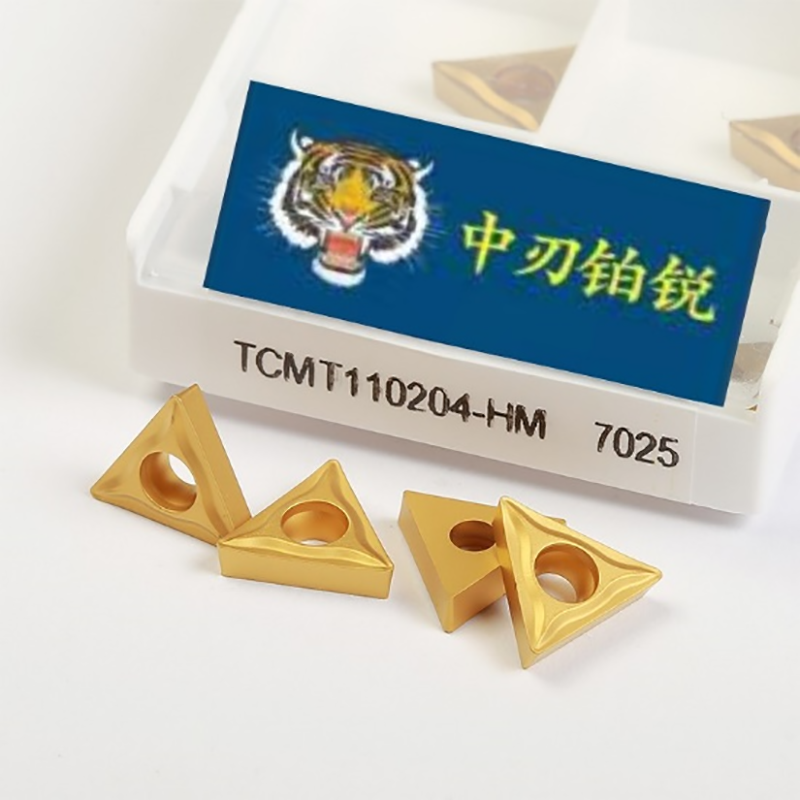

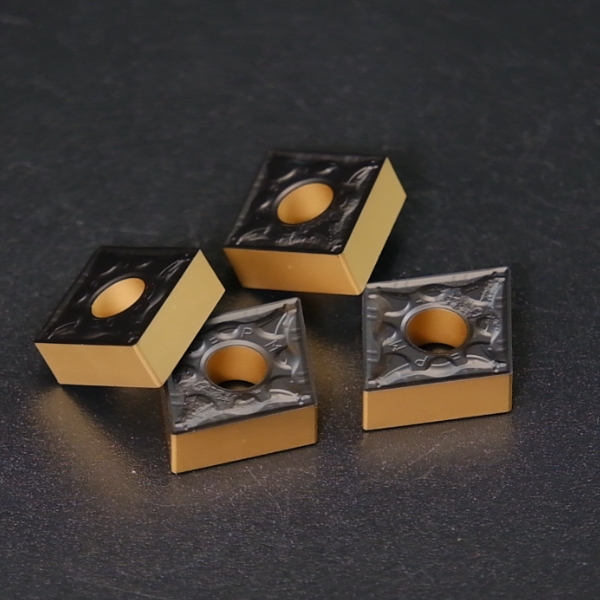

Factory Sale Tungsten Carbide Insert Milling Cutter Turning tools TCMT110204

Type

1.Tungsten carbide tools for Turning inserts

CNMG/TNMG/WNMG/DNMG/SNMG/VNMG/CCMT/DCMT/SCMT/TCMT/VBMT/KNUX

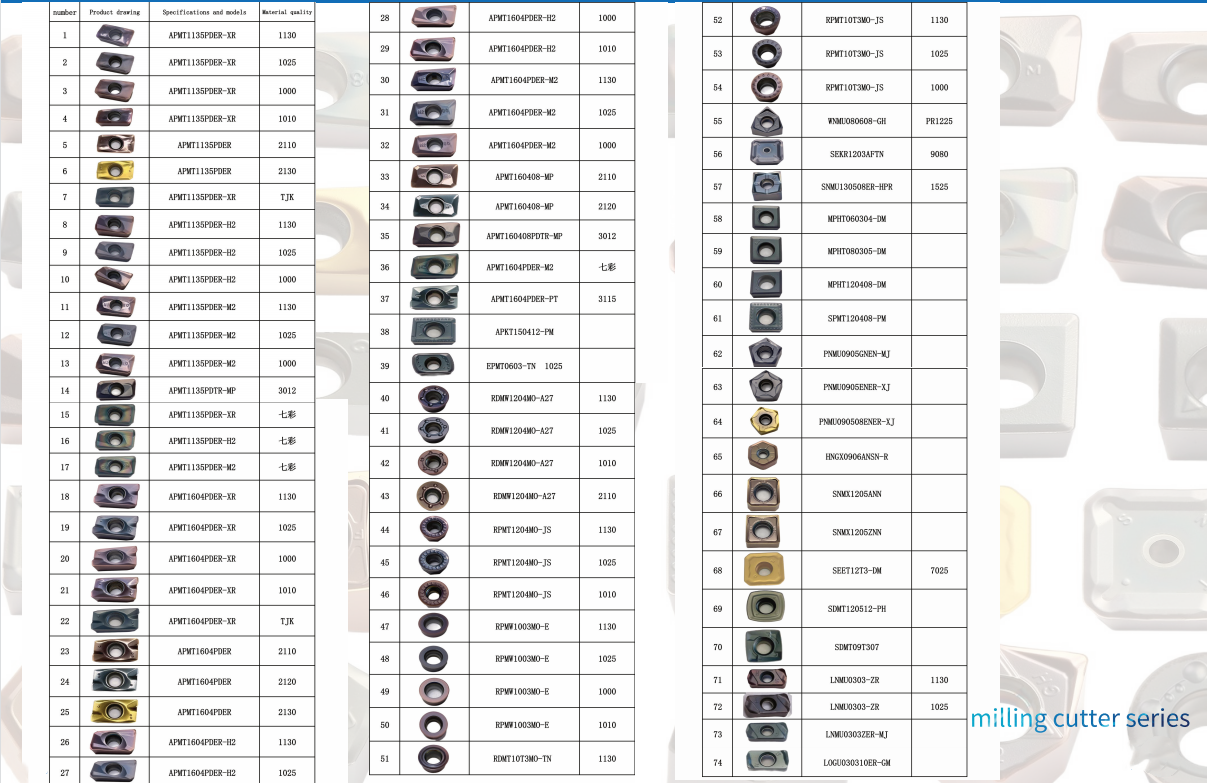

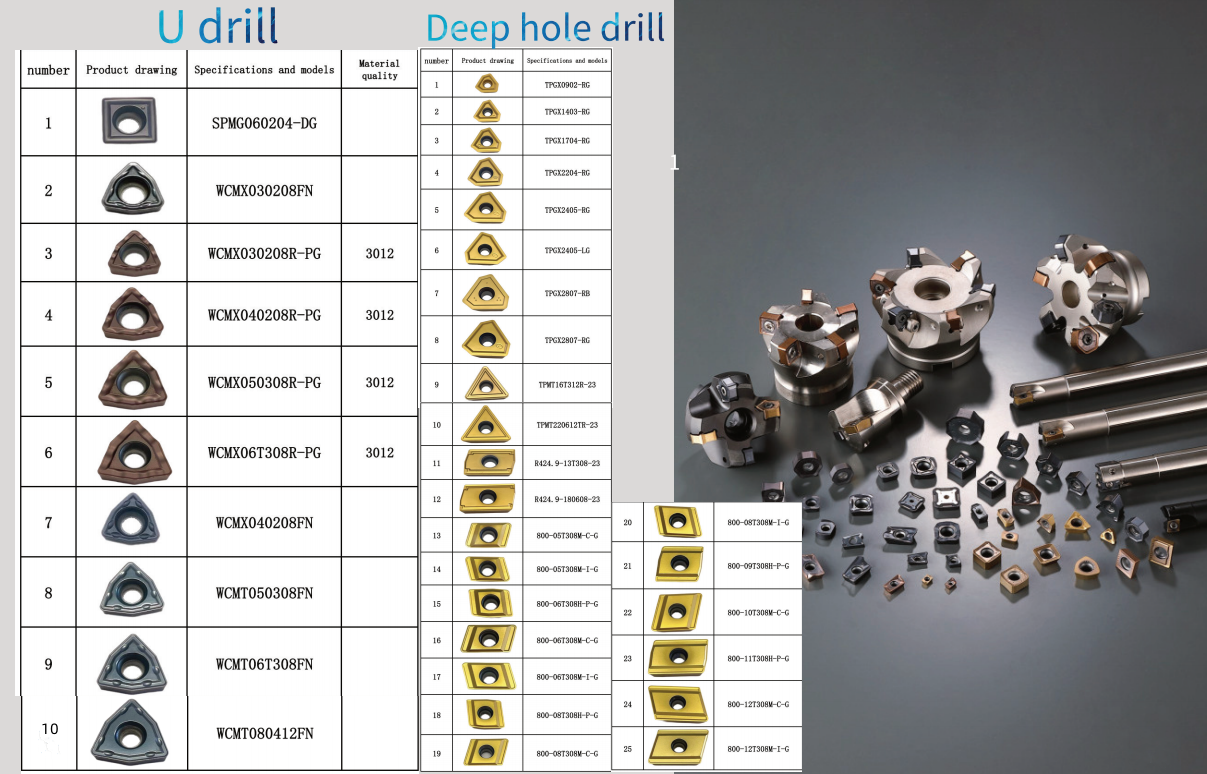

2.Tungsten carbide tools for milling inserts

APKT/APMT/RPKW/RDKW/RCMT/SPKN/TPKN

3.Tungsten carbide tools for Aluminium inserts cutting

CCGT/DCGX/SCGX/TCGX/VCGX

4.PCD &PCBN Tungsten carbide tools turning for inserts

CNGA/DNGA/SNGA/TNGA/VNGA/CCGW/DCGW/TCGW/VBGW

Main Application

Suitable for semi-finishing to coarse steel processing. Suitable for steel and stainless steel. 201, 304, 316, 316L stainless steel material.

Application Machine: Side row cutter lathe turning machine Towel cutter lathe turning machine

Automatic lathe turning machine

CAM type Swiss lathe machining

Turning Applicable machine

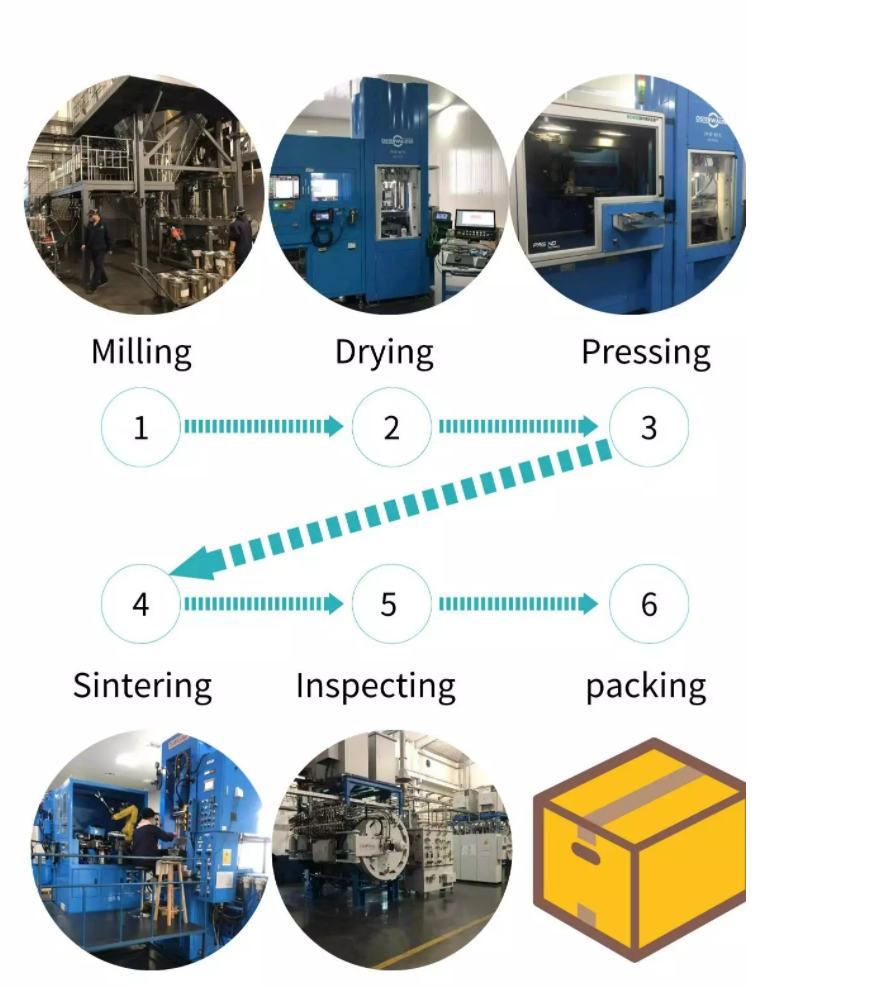

Production process

Material Grade Introduction

Introduction of turning material introduction:

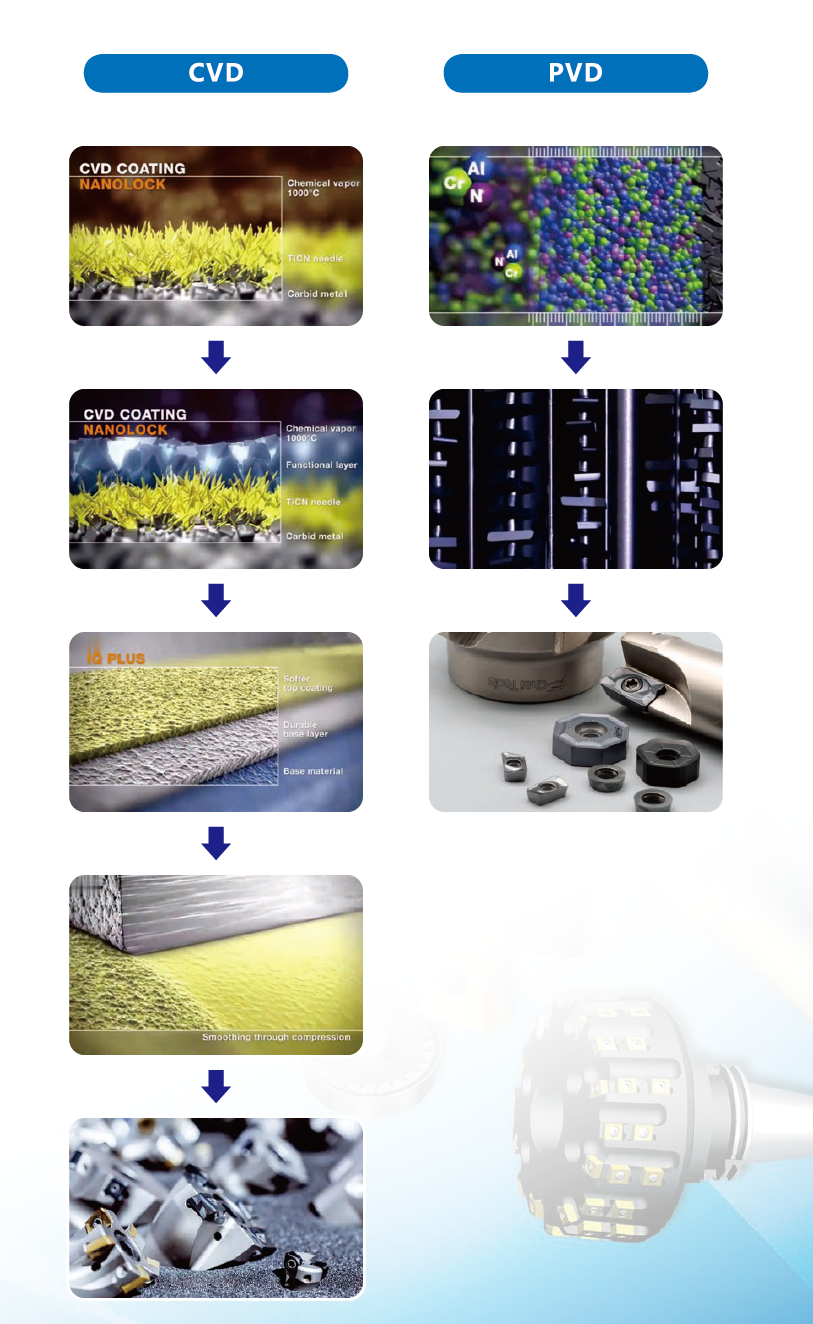

7215 has high strength and toughness of high toxicity resistance matrix, combined with MT-TICN, AL2O3,TIN excellent combination of coating process, and then through advanced coating post-treatment to eliminate the internal stress of blade layer, suitable for ordinary steel finishing.

7125 edge safety of high strength, high toughness matrix combined with MT-TICN and superfriction AL203 coating process, and then through advanced coating post-treatment process to eliminate the internal stress of the coating, suitable for ordinary steel rough processing, semi-finishing and part of the workpiece roughness requirements are not high finishing.

4025 high corrosion resistance, and through a certain pressure sintering process of high strength matrix and MT-TICN and super thick AL2O3 coating excellent combination, with advanced coating post-treatment technology to obtain smooth coating surface, suitable for the rough machining, semi-finishing and finishing of cast iron.

1030 fine grain, excellent deformation resistance and through the pressure sintering process to obtain ultra-high strength and wear resistance matrix, with nano PVD coating process, and then through advanced coating post-treatment to obtain smooth coating surface, suitable for ordinary steel finishing, quenched steel, chromium plated steel and stainless steel semi-finishing and finishing.

1120 ultra-fine grain, excellent deformation resistance, and through the pressure sintering process to obtain high strength and wear resistance matrix, with nano SI containing PVD coating process, after advanced coating post-treatment to obtain smooth coating surface. Suitable for grooving and cutting of ordinary steel, hardened steel and cast iron.

Introduction of milling and drilling materials

1030 NC-TIALN coating combined with strong and ductile matrix of fine particles is suitable for coarse and semi-finished milling of all kinds of processed materials. Grooving, cutting and drilling of half aperture.

1130 NC-TIALN coating containing SI is combined with fine particles and good toughness of hard alloy matrix, suitable for stainless steel, cast iron phase and semi-finish to processing, to achieve a perfect combination of safety and wear resistance.

5035 added wear and high temperature resistance elements of CVD coating, high coating hardness and excellent high temperature resistance to provide effective protection for the cutting edge, special coating treatment technology, coating and matrix more firmly, suitable for high temperature alloy, titanium alloy materials precision milling processing.

5135 NC-TIALN coating containing SI combined with carbide matrix with excellent impact toughness, suitable for steel parts, stainless steel, grooving, cutting deep cutting, fast feeding processing and large aperture drilling processing.

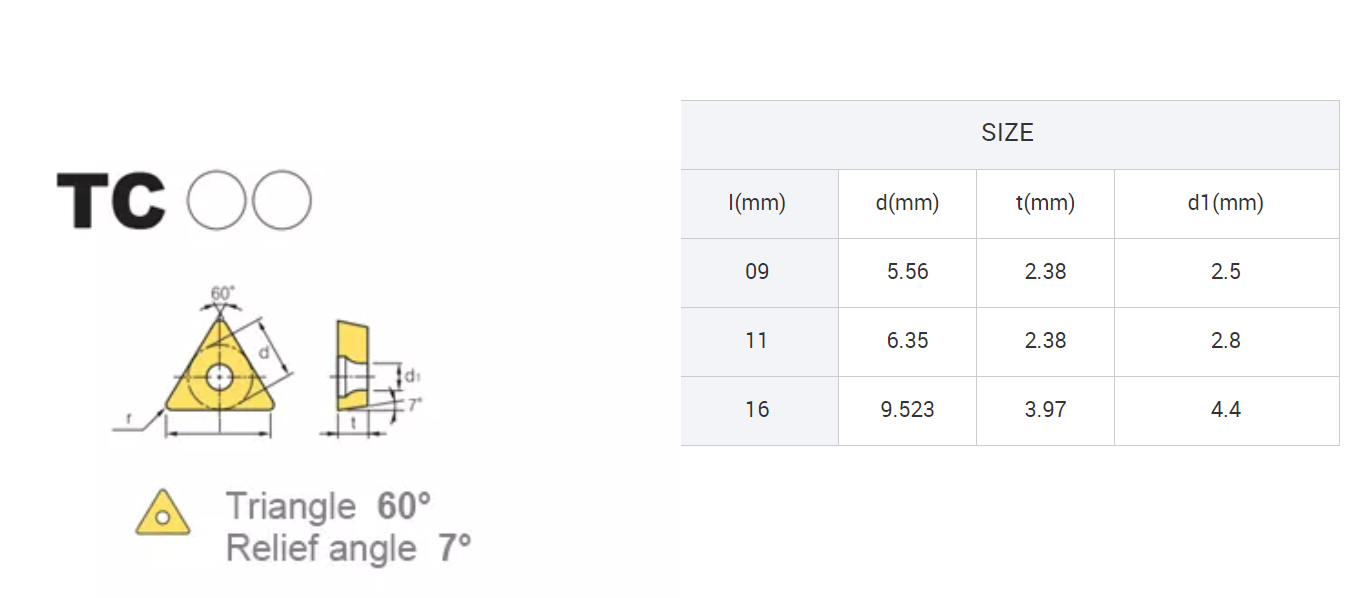

Product Specifications

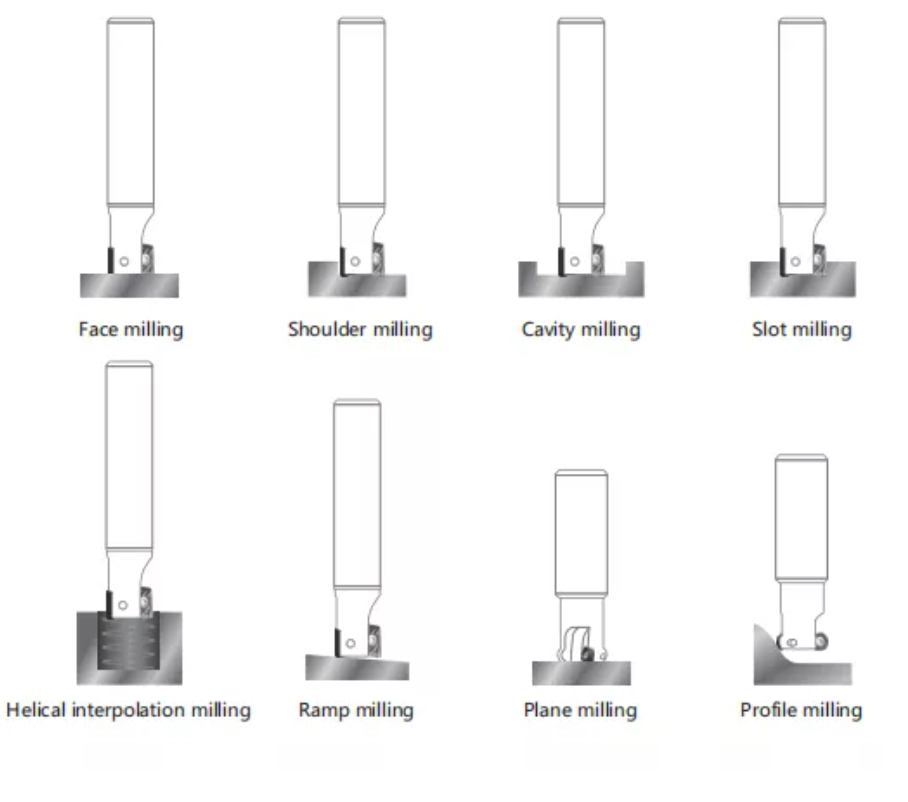

Whether you need a general milling or heavy milling inserts for face milling, shoulder milling, slot milling, profile milling, or ramp milling, or even milling higher requirements of surface smoothness, Our engineer can turn your design into a milling insert in just days.

COATING DISPLAY

PACKAGE AND SHIPMENT

100% anti-water package.

One plastic pipe pack one piece,10 pcs per group.

Put goods enclosed with air bubble paper into box.

Other package is accepted according to customer's requirement.

Orders processed timely after the payment verification. we have many shipping ways, like DHL, Fedex, EMS and so on, will choose the best one for you.

Advantages

1. All raw materials are tested in terms of density, hardness and T.R.S before use.

2. Every piece of product goes through in-process and final inspection.

3. Every batch of product can be traced.

Buying tips

1.Picture : The picture showing at our store are taken on the true products. Because of different light condition or camera

problem, if the color of packing is a little different, that would be normal.

2.Payment :We accept payment by ESCROW. Credit Cards, T/T, West Union and Paypal If you have any problem of payment, please contact us asap.

3.Refund :100% Money Back Guarantee on each item Please contact us within 24 hours upon your receipt of the item. A refund will be rendered

in the event that the item(s) is not as described and once the item(s)has been sent back in original condition.

4.Delivery :By sea, by air or by express courer.

5.Feedback :Your satisfaction and positive feedback is very important to us. Please leave positive feedback and 5 stars if you are satisfied

with our items and service.

If you have any problems with our items or services, please feel free to contact us first before you leave negative feedback. We

will solve the problems quickly and promise you 100% good products and services.

Your encouragement and support is our continuously forward momentum.

Certificates

Production Equipment

QC Equipments