APMT1135 Tungsten Carbide Milling Tools Inserts pder CNC Indexable Cutting Tools

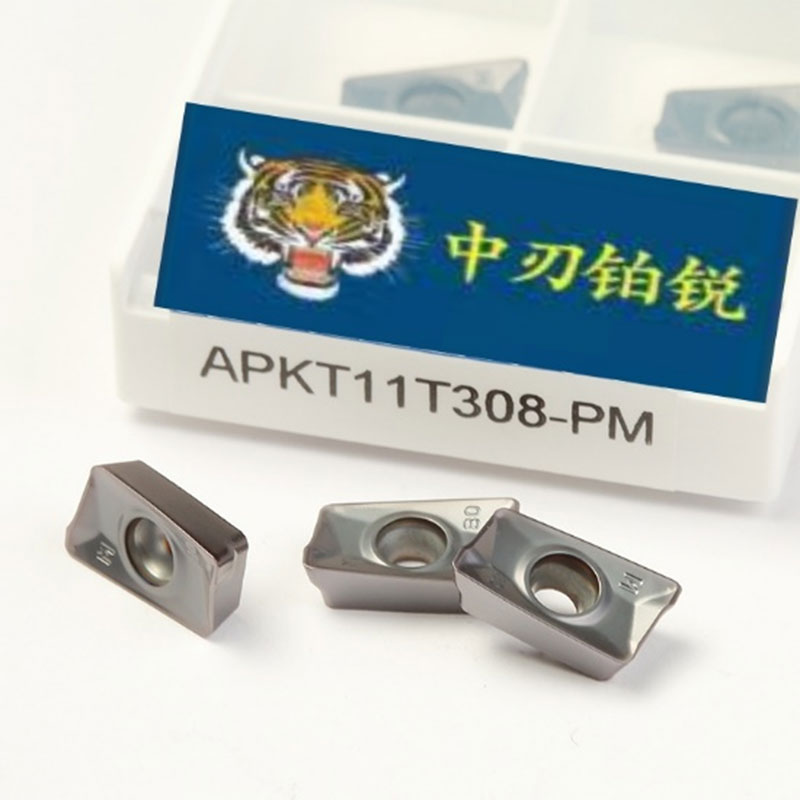

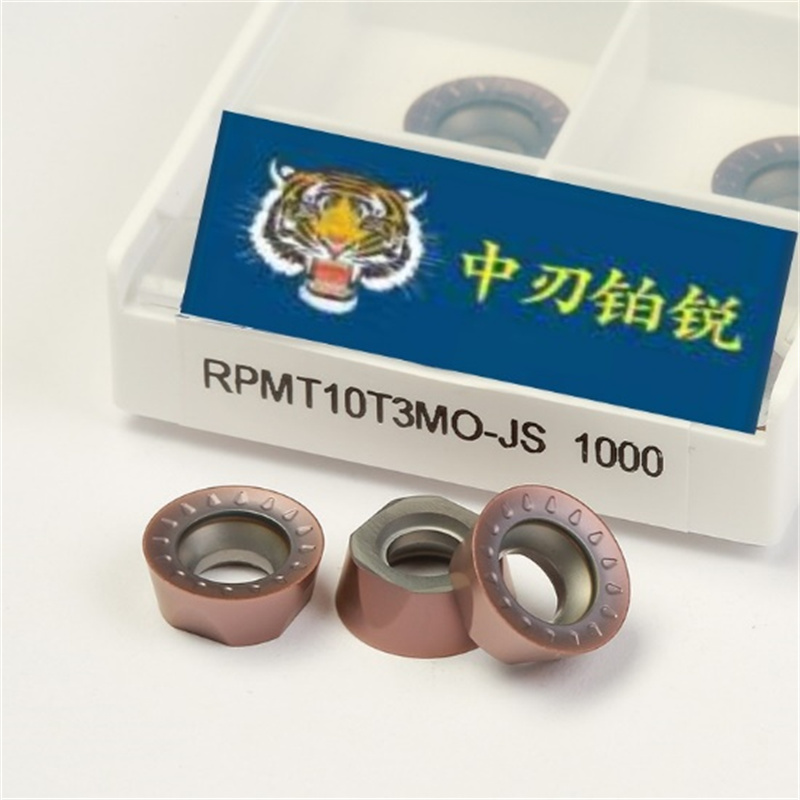

Major Products

CNC inserts are the general name for indexable turning inserts and are the mainstream products in modern metal cutting applications. Mainly used in metal turning, milling, cutting and grooving, thread turning and other fields.

CNC inserts are mainly used in metal turning, milling, cutting and grooving, thread turning and other fields. According to the material can be divided into coated blades, cermet blades, non-metallic ceramic blades, carbide blades, super hard blades and so on. It is characterized by high efficiency and high wear resistance, which is more than 4 times more efficient than traditional welding inserts and alloy inserts. With the continuous advancement of coating technology, breakthroughs in key technologies of wear resistance and high temperature resistance will further improve efficiency and reduce processing costs.

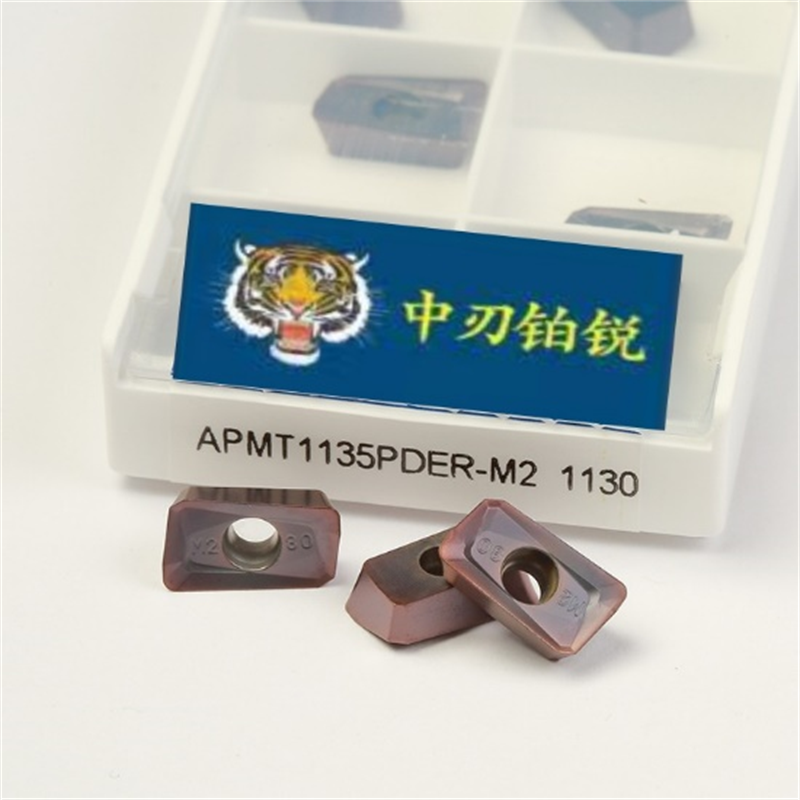

Model NO.: APMT1135PDER-M2

Item: CNC Tungsten Carbide Milling Inserts

Manufacturing Process: Mould Processing

Milling Hardness: HRC 0-45

Usage: Milling Tools

Application: Metal Working Tools

Service: OEM

Machine Type: Lathe Tools

Transport Package: Standard Exporting Package

Specification: APMT1135PDER-M2

Origin: China

HS Code:8208101900

Production Capacity:400000PCS/Month

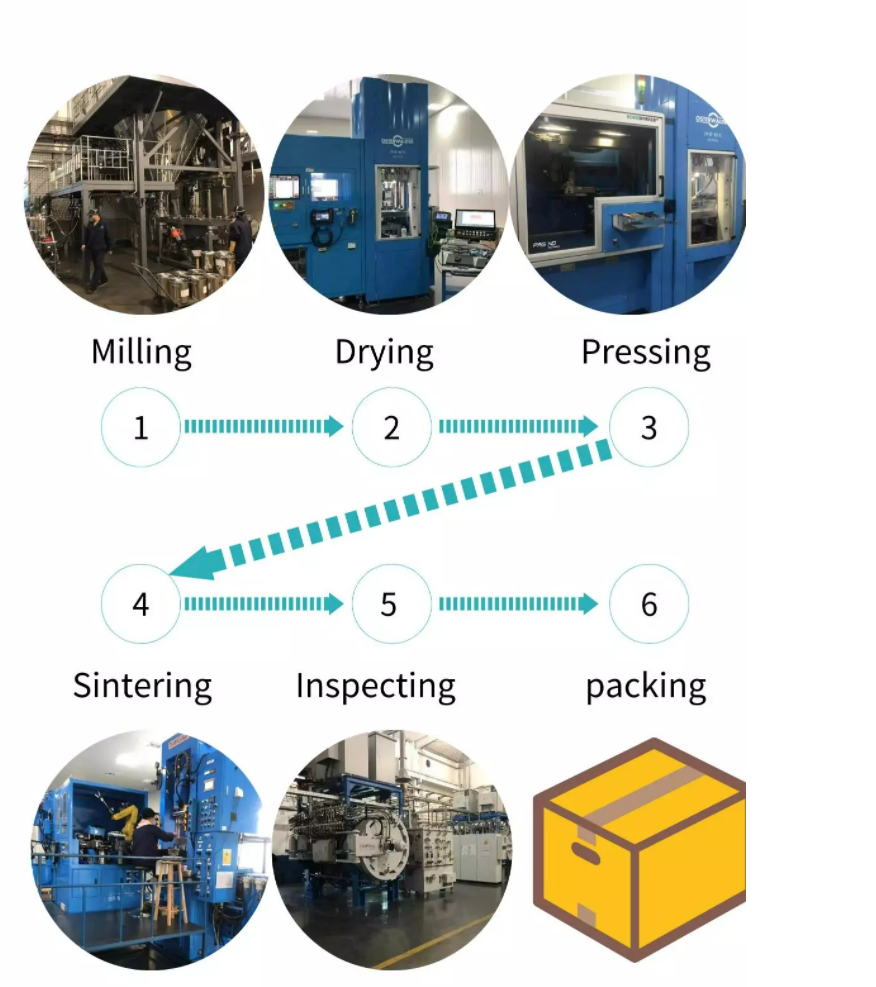

Production process

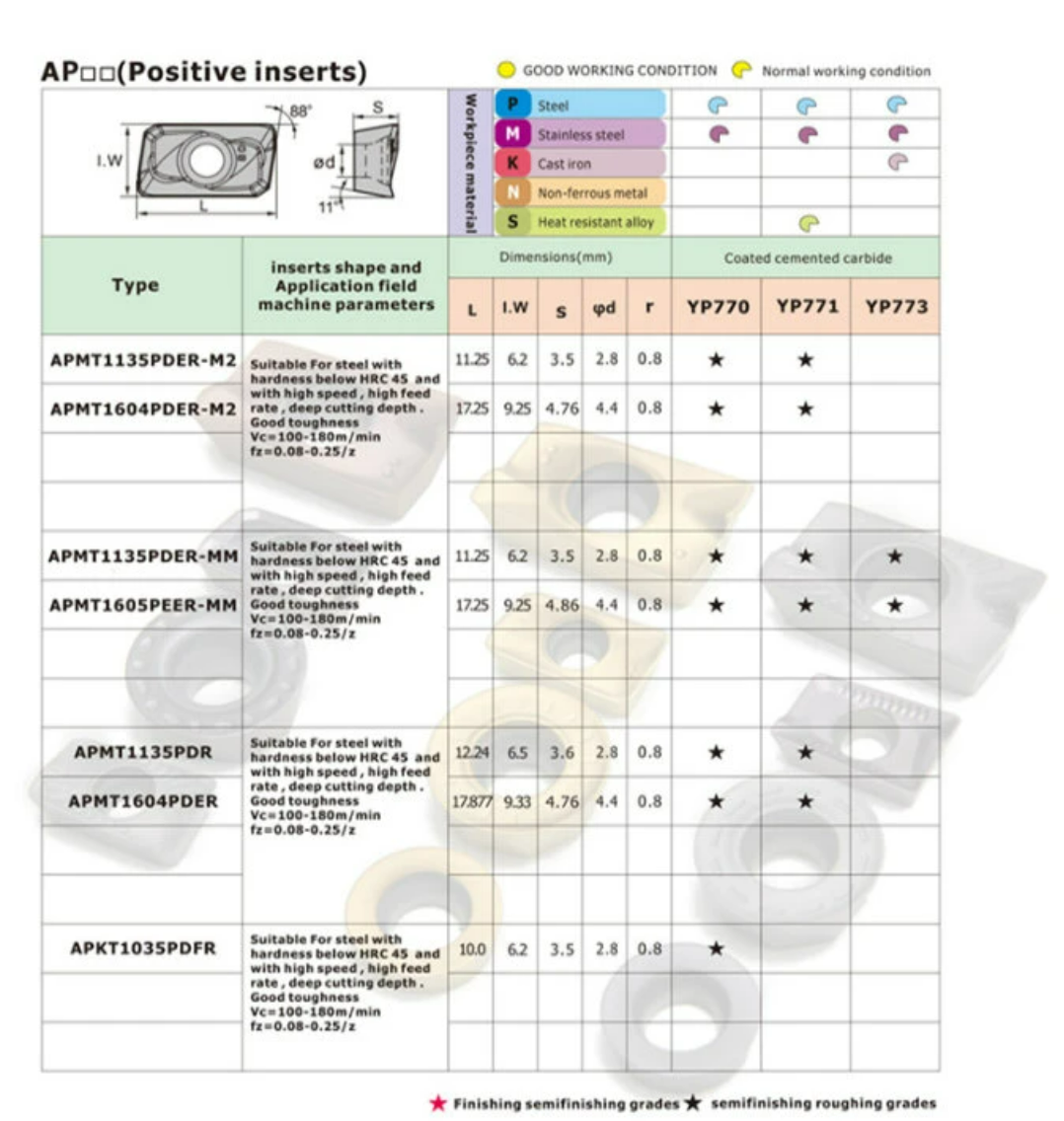

Product Specifications

Coating Display

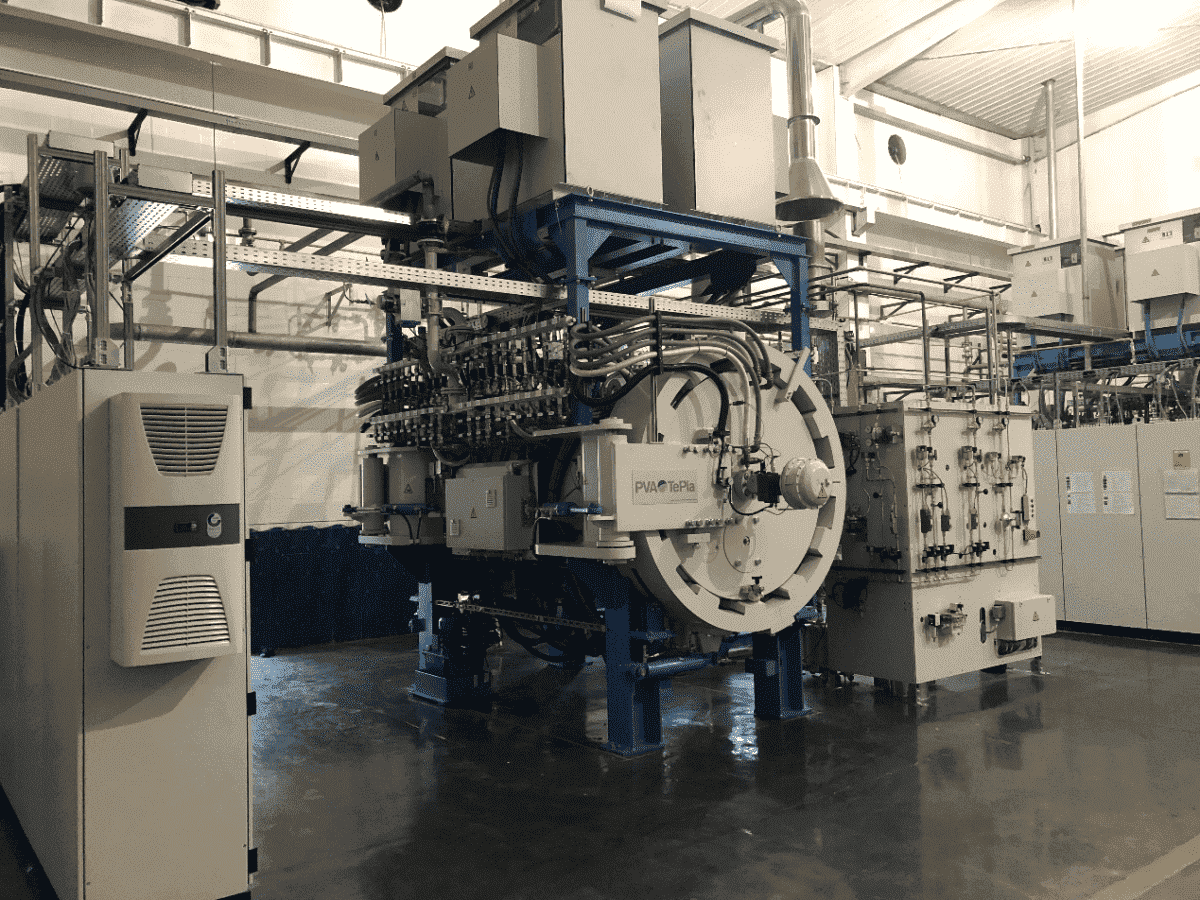

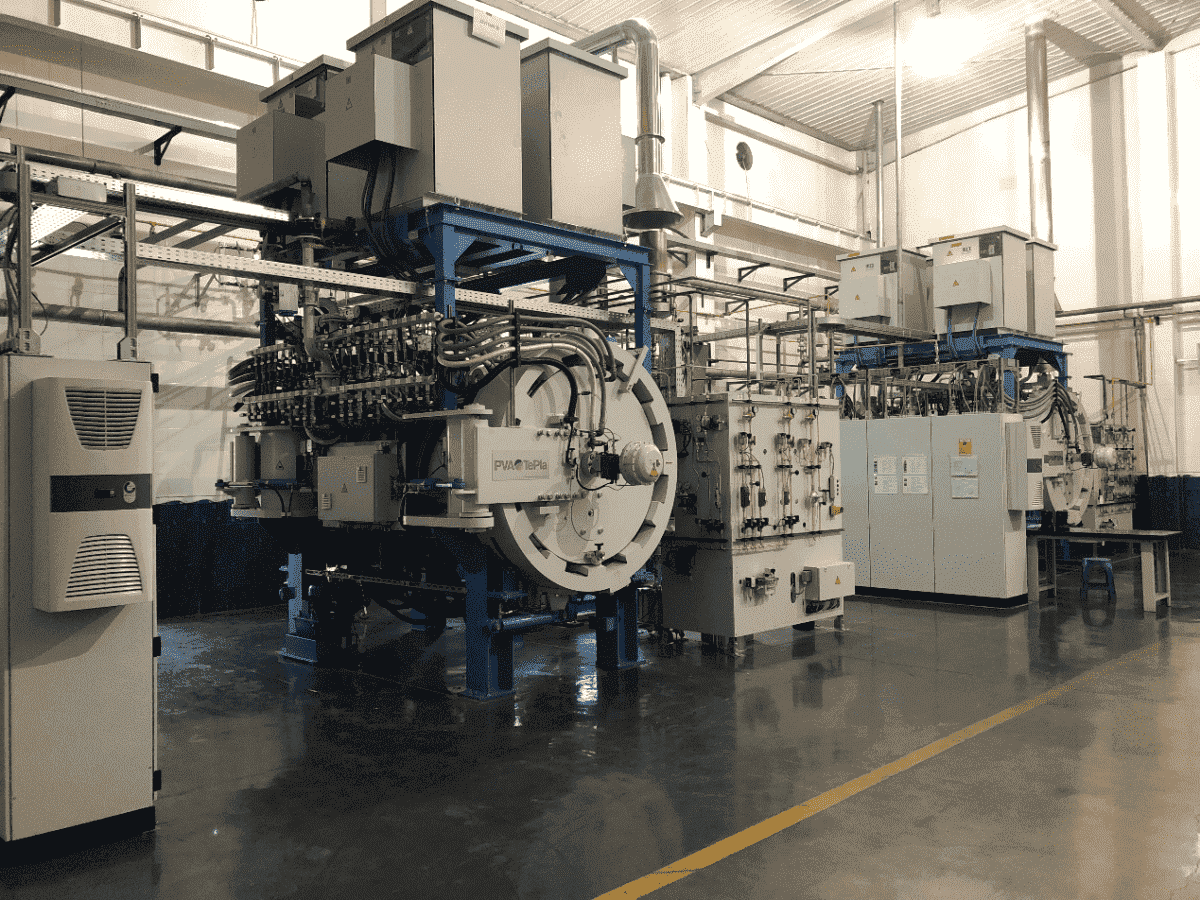

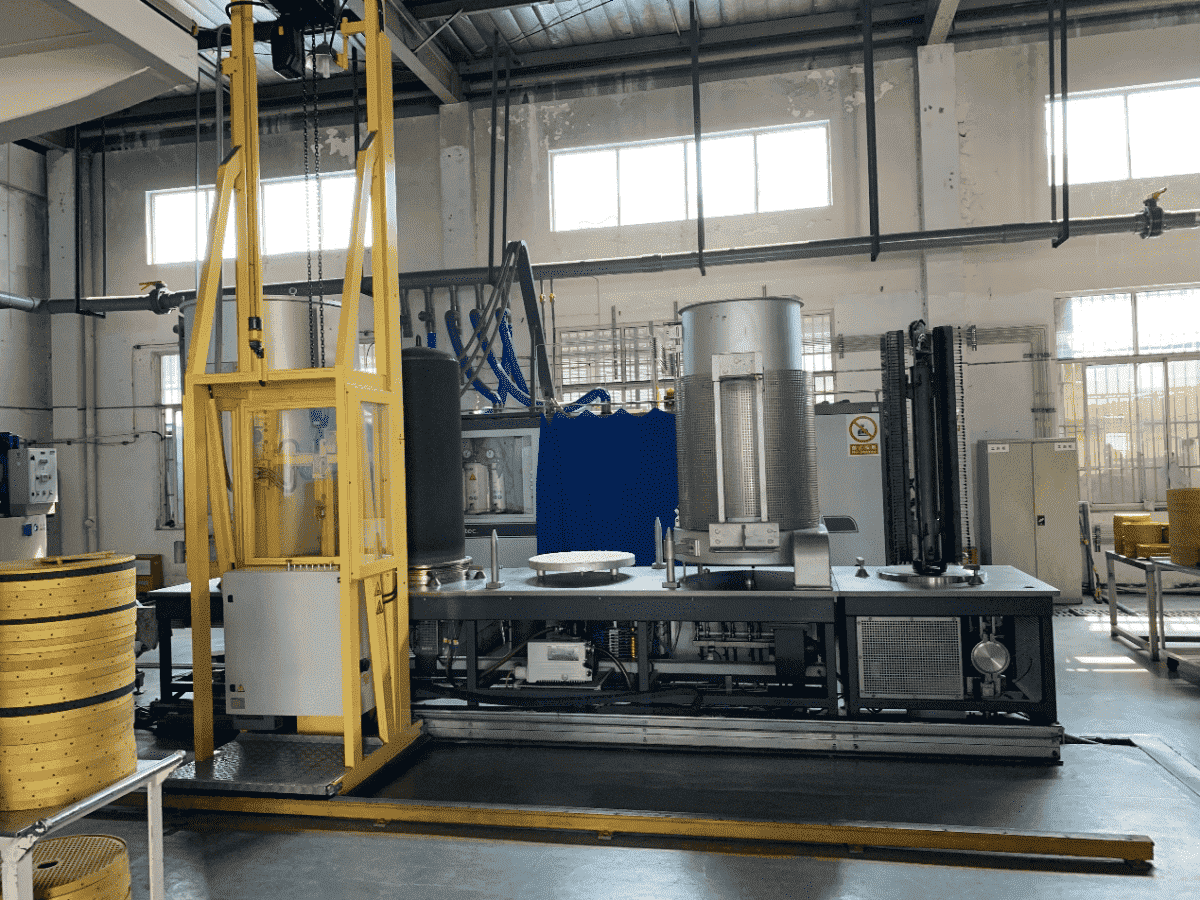

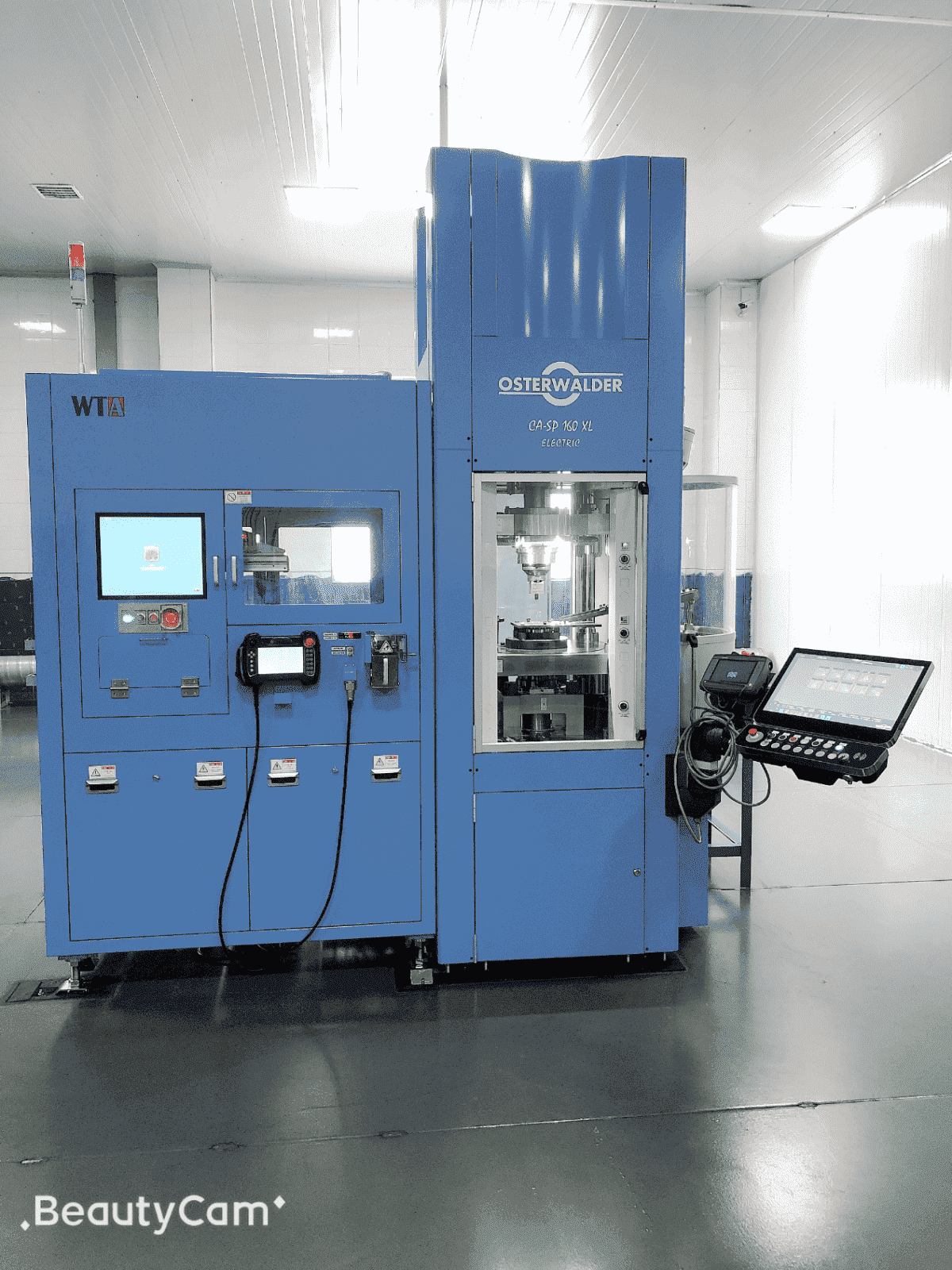

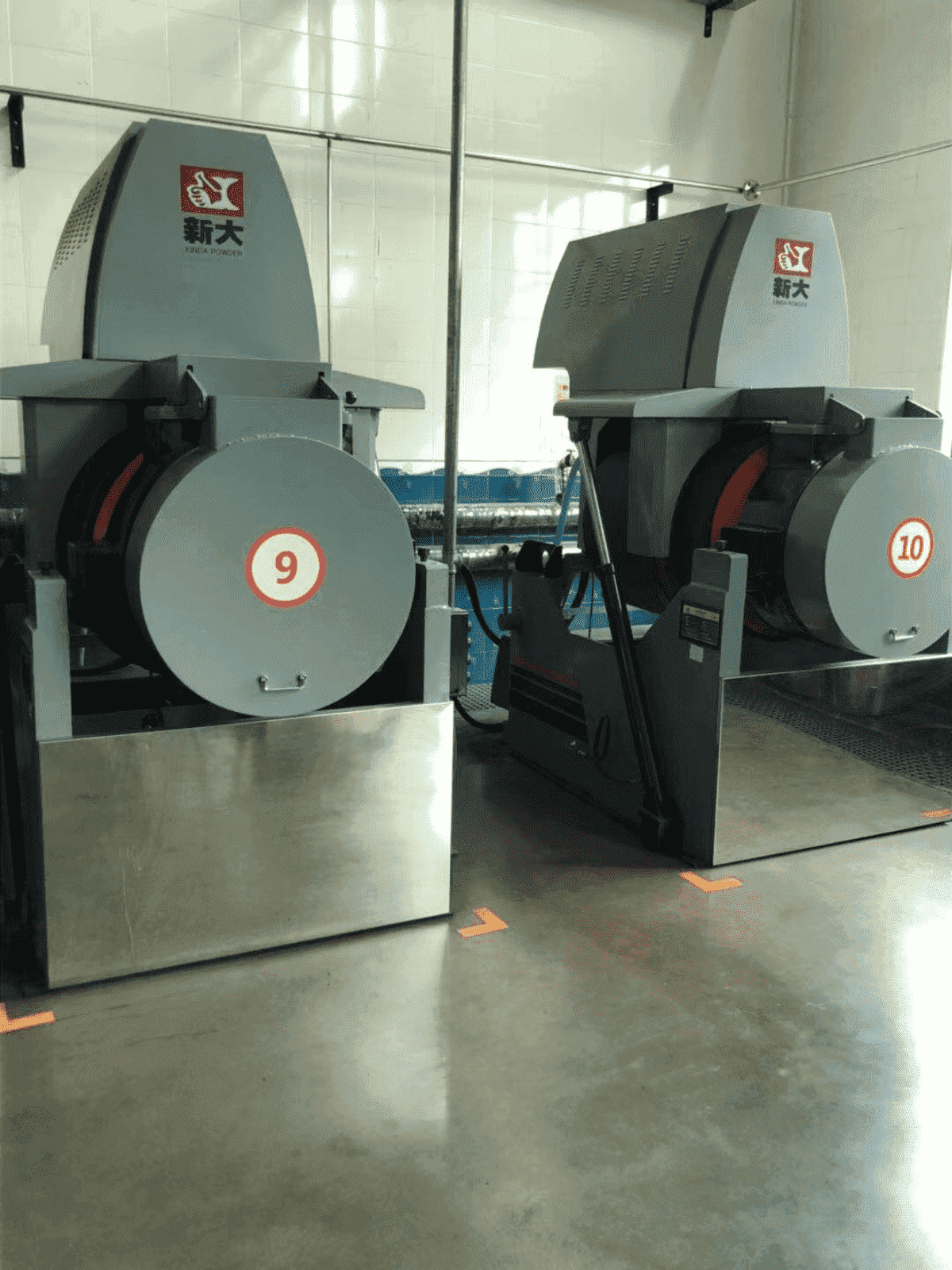

Production Equipment

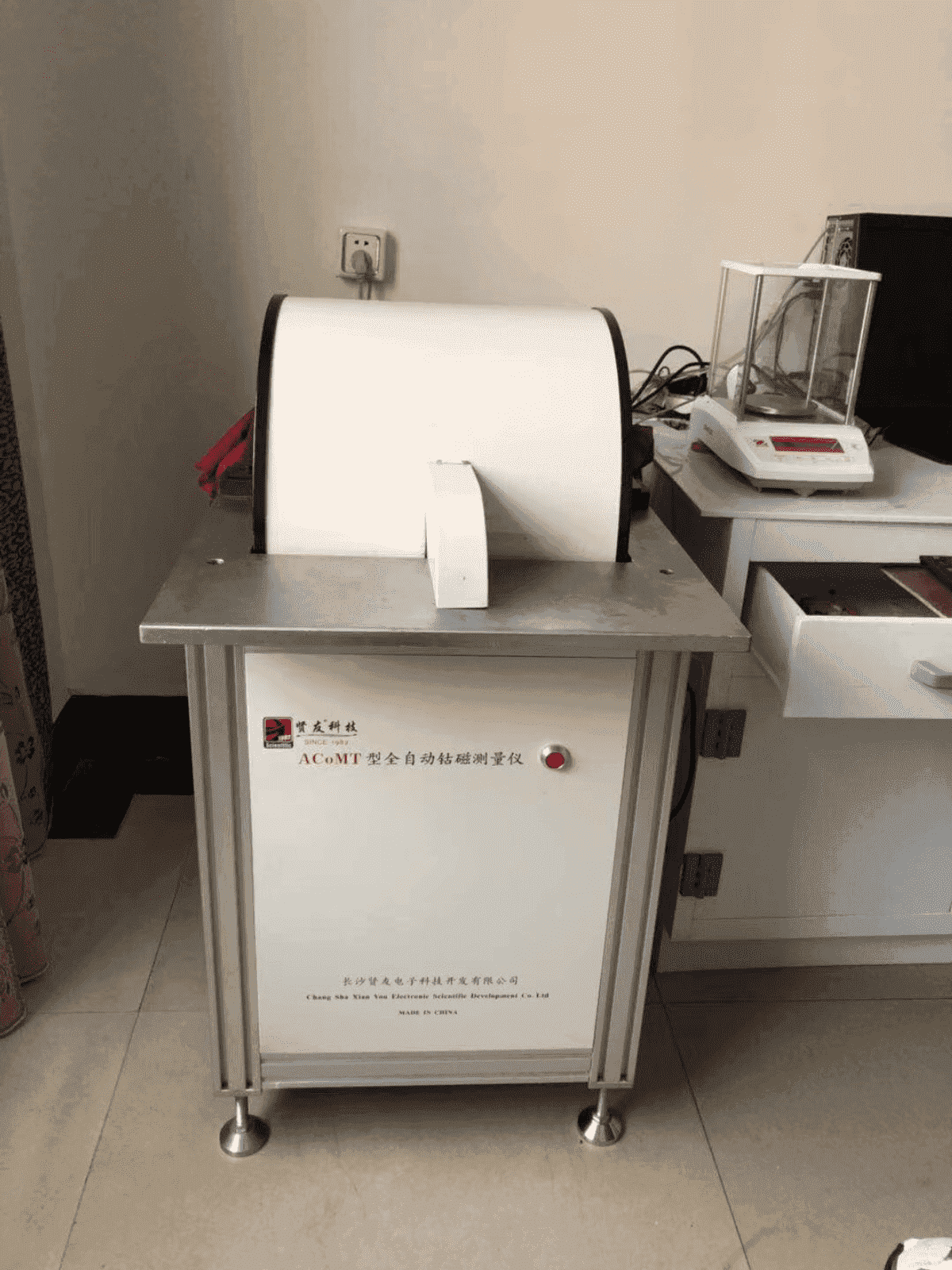

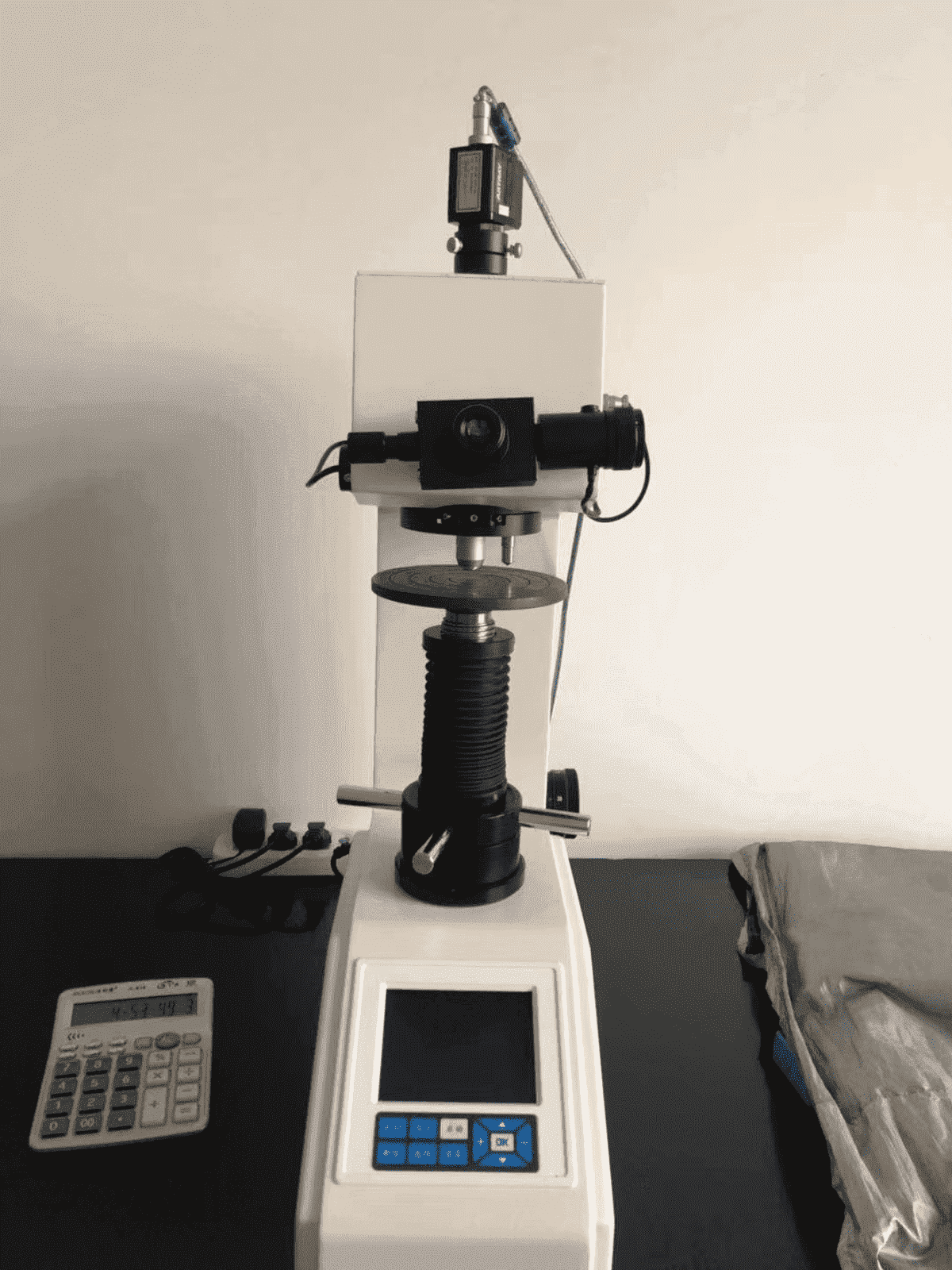

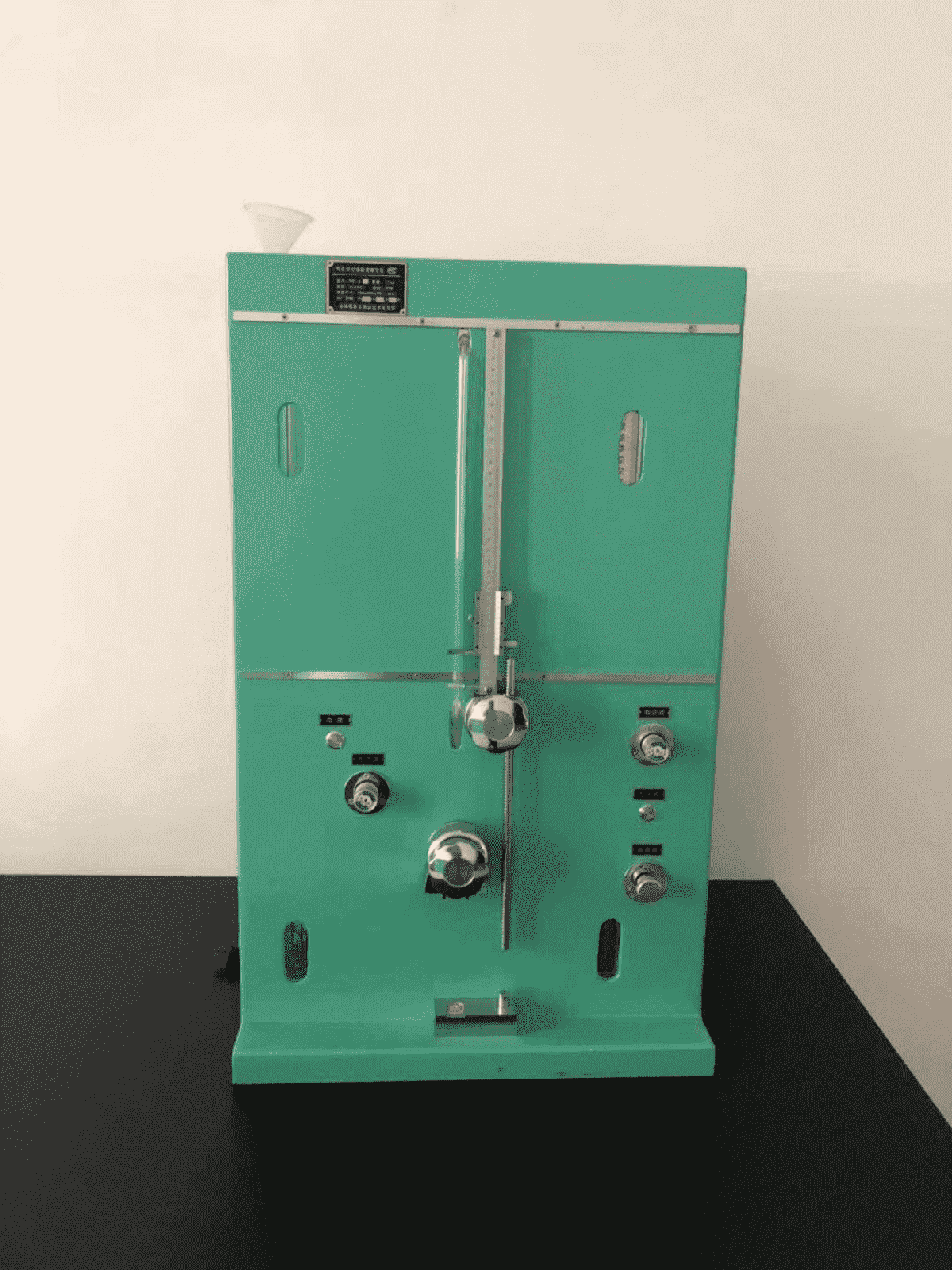

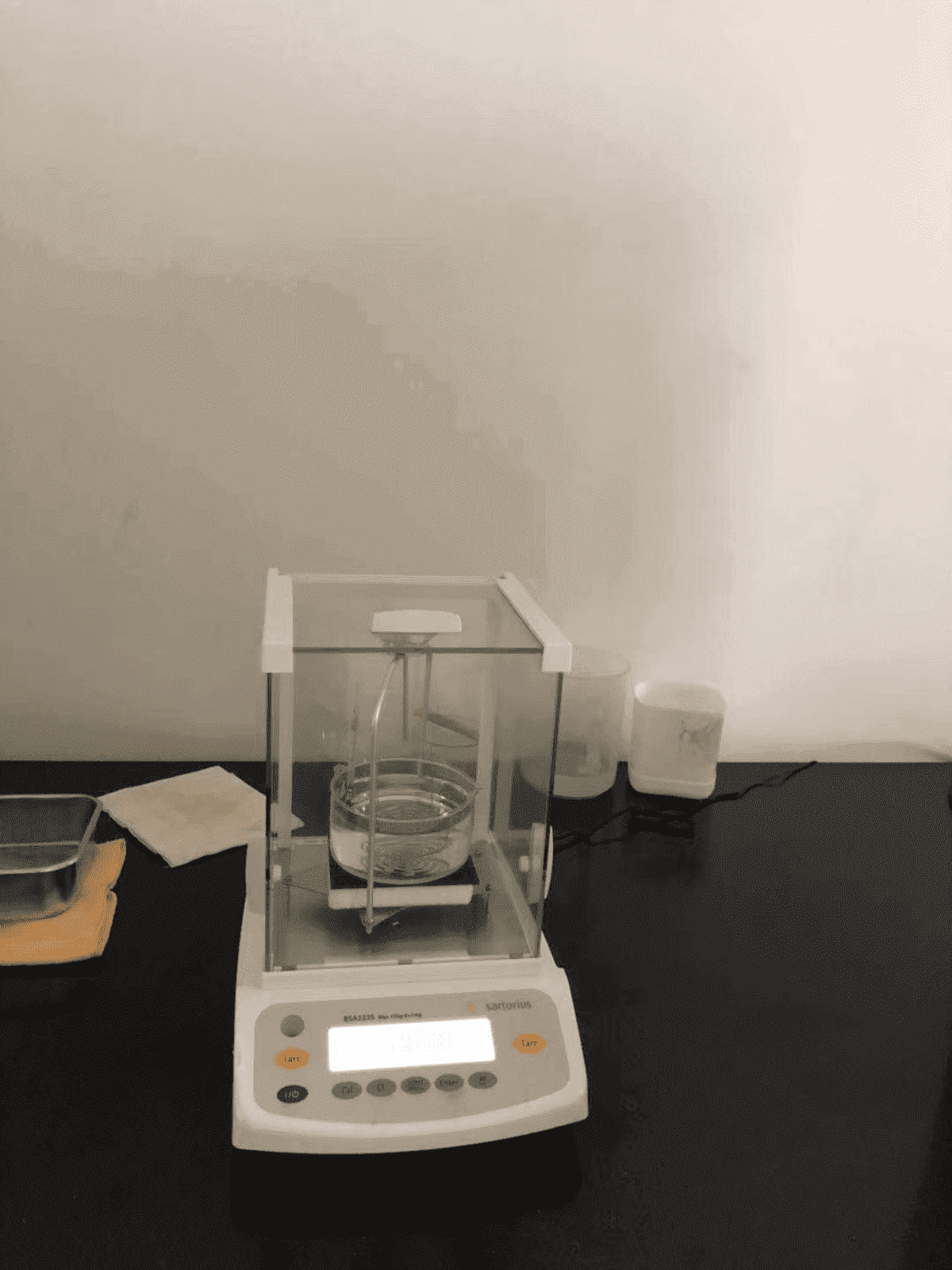

QC Equipments

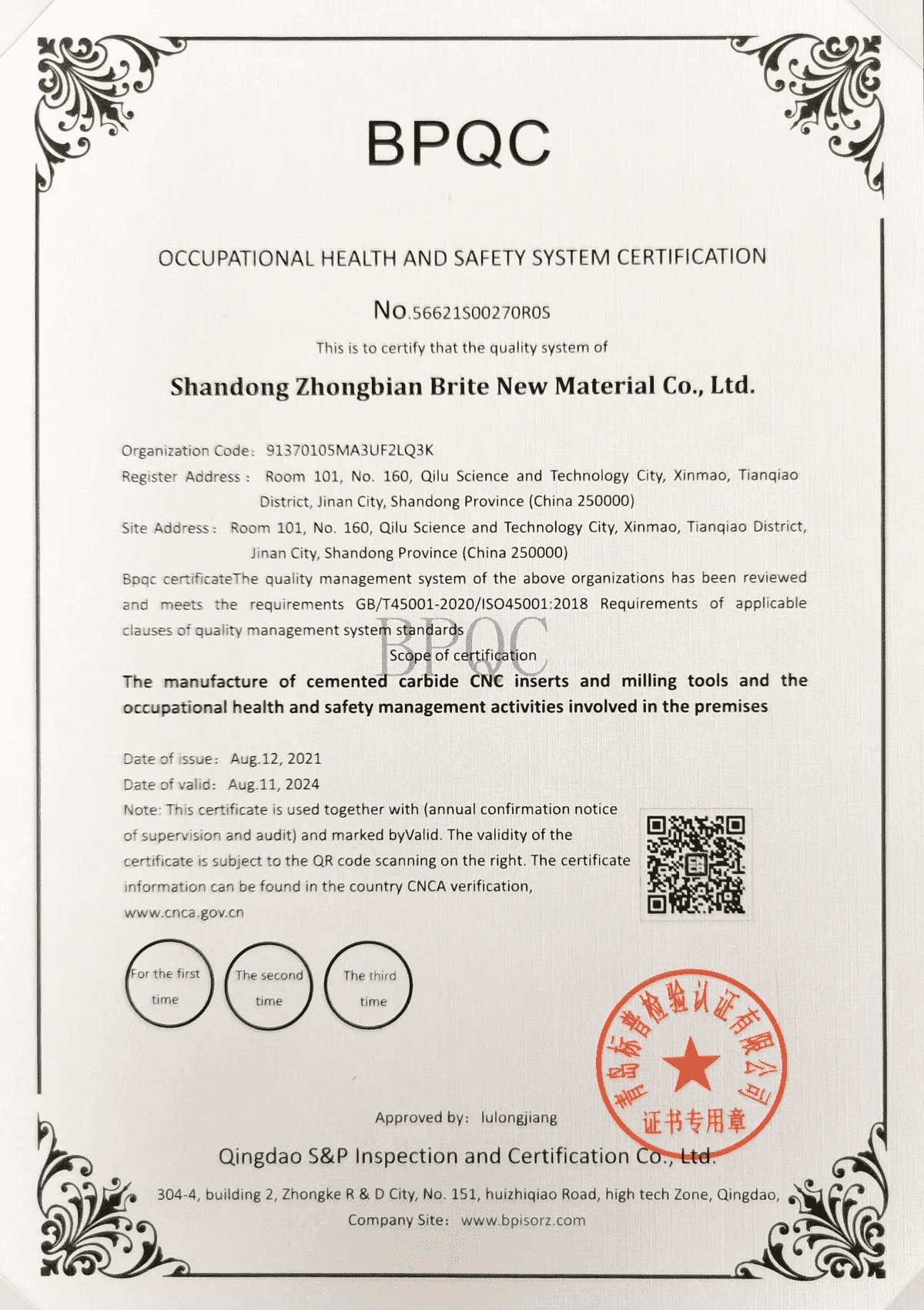

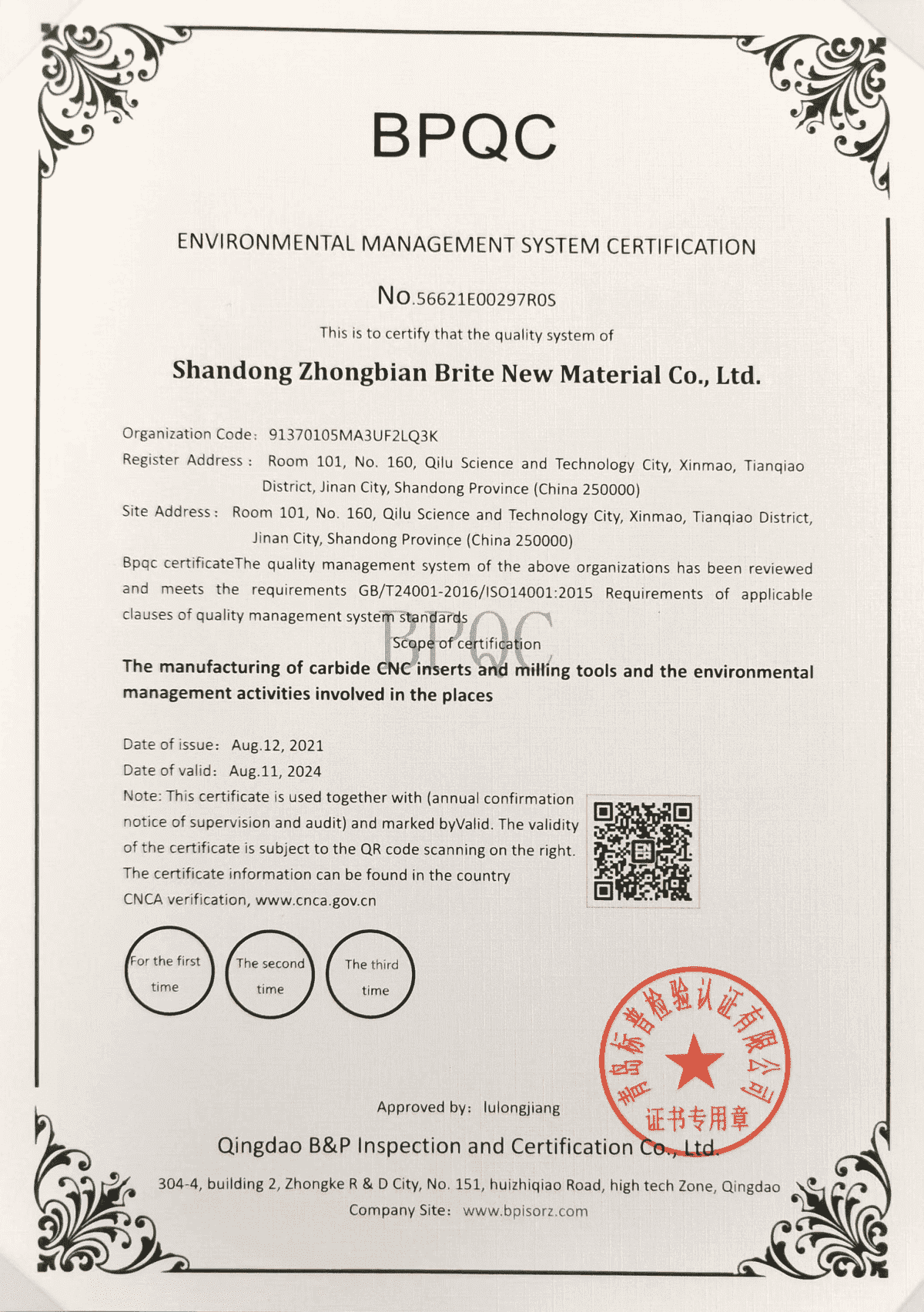

Certificates

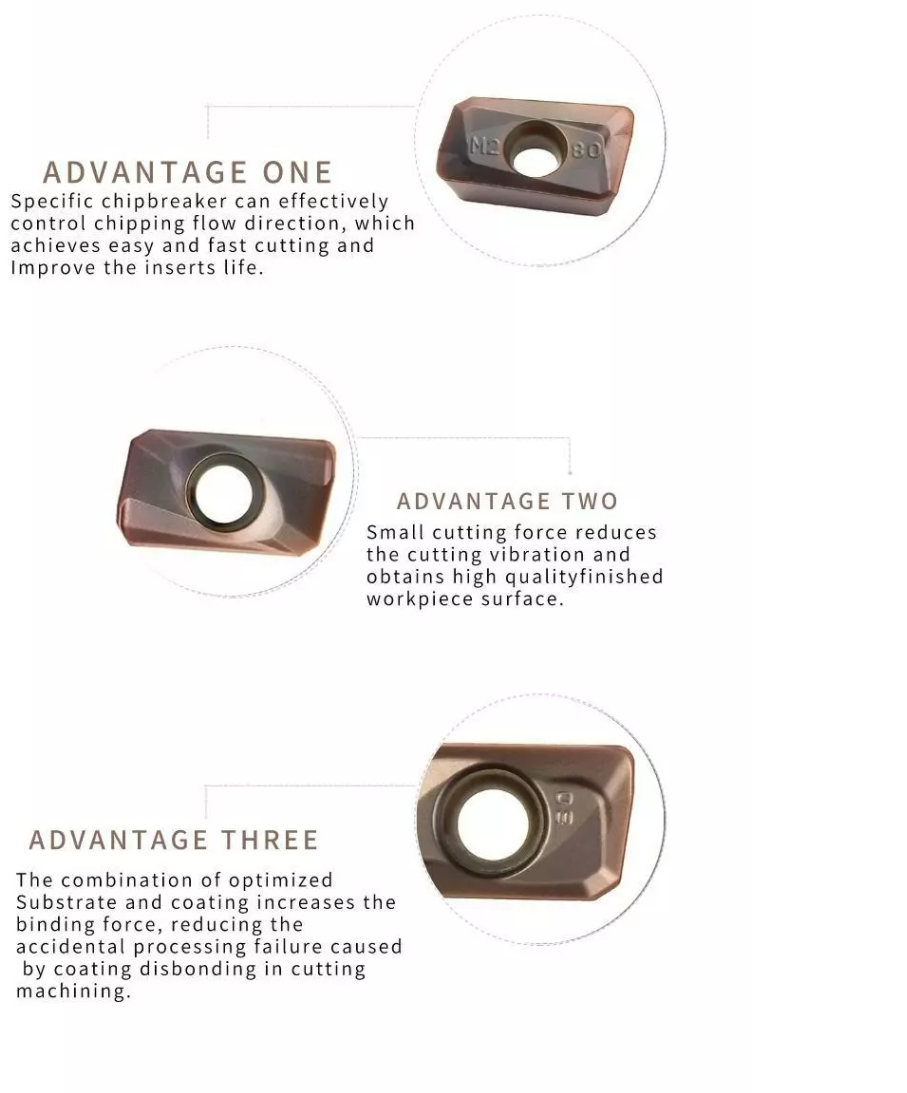

Advantages

1. Produced with advanced equipments and process

2. High quality with competitive price.

3. Large stock available.

4. 100% factory manufacture and factory direct sales

5. Small orders are also welcomed.

6. Delivery fast.

Customer Notice

1. Top quality in China. Our tungsten carbide tools inserts quality of steel cutting, cast iron cutting, stainless steel cutting inserts is equal to ZCC-CT.

2. Most advanced equipments. Our production equipments include "HIP-Sinter furnace, CNC high precision presser, Five axis machining center, CVD coating furnace, PVD coating furnace."

3. Strong technical support. Our senior engineers are engaged in cutting tools industry for decades, we provide excellent service in grade selection, cutting data recommendation, and solution for your tools.

4 Reputation among our customers. We have big customers of carbide inserts in Europe, such as Germany, Italy, UK, Poland, Czech, Ukraine. In South America, such as Brazil, Peru. And in Asia, such as India, Iran.